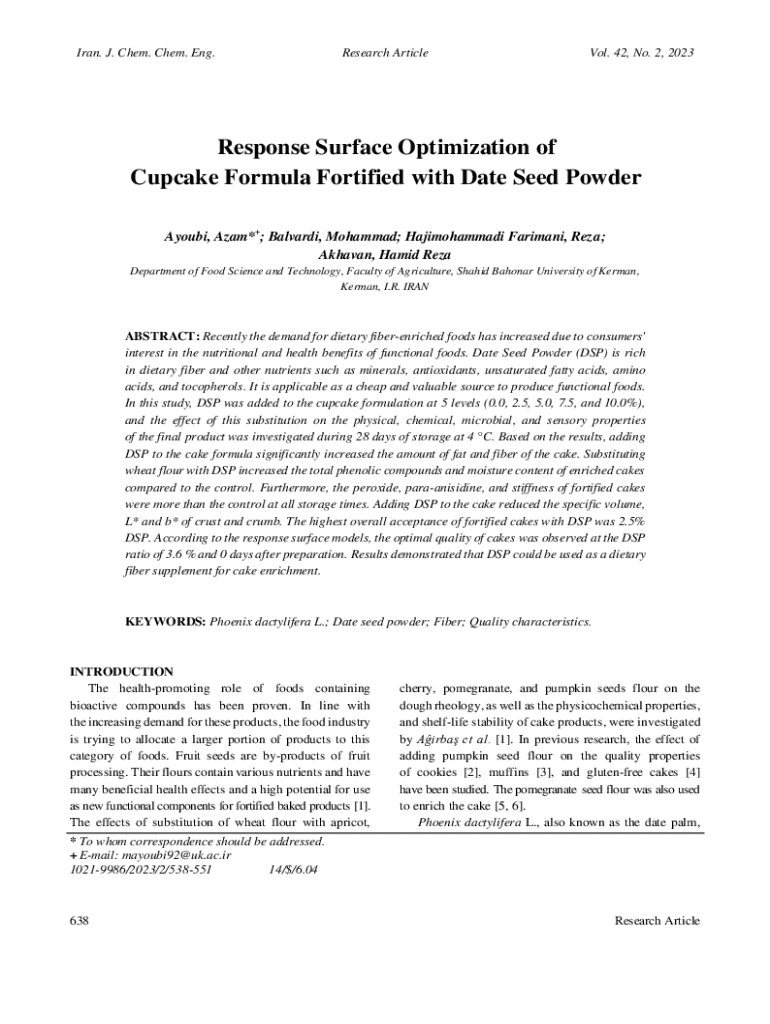

Get the free Response Surface Optimization of Cupcake Formula ...

Get, Create, Make and Sign response surface optimization of

Editing response surface optimization of online

Uncompromising security for your PDF editing and eSignature needs

How to fill out response surface optimization of

How to fill out response surface optimization of

Who needs response surface optimization of?

Response surface optimization of form: A comprehensive guide

Understanding response surface optimization

Response Surface Methodology (RSM) is a powerful statistical technique that focuses on optimizing processes and systems by exploring the relationships between multiple variables. RSM is primarily concerned with understanding how the responses are affected by different factors in a process and finding the optimum conditions for desired outcomes. This methodology is vital in various fields, where optimization can lead to better product formulations, improved production methods, and more efficient processes.

RSM's importance lies in its ability to inform better decision-making by providing insights through graphical representation of data, allowing stakeholders to visualize complex relationships intuitively. In the context of response surface optimization of form, industries can benefit greatly by applying RSM to refine their processes, maximize yield, and enhance product quality.

Applications of RSM in various industries

RSM finds applications across diverse sectors, including:

Key concepts in response surface optimization

To effectively implement RSM, it is essential to understand a few key concepts, the foremost being response variables and factors. Response variables are the measurable outcomes influenced by the factors you manipulate within experiments. Identifying these response variables is critical since they reflect the performance and quality of the product or process being optimized.

Factors, which can be independent variables, are the parameters that you control in your experiment. For example, in a manufacturing setting, factors might include temperature, pressure, and ingredient concentrations. By varying these factors thoughtfully, you can better understand their relationship with the response variables.

Design of experiments in RSM

The design of experiments (DOE) is a fundamental aspect of RSM, setting the foundation for how experiments are structured. A full factorial design allows for the exploration of all combinations of factors at different levels, providing comprehensive insights into their effects. In contrast, a fractional factorial design focuses on a subset of combinations, significantly reducing the number of experiments needed while still providing useful information.

Choosing the appropriate design is crucial as it should align with the objectives and constraints of your optimization project. In settings with limited resources, fractional designs can be especially effective, while full factorial designs may be preferable when comprehensive data is needed.

Steps in response surface optimization

The process of response surface optimization typically involves several well-defined steps, each contributing to the eventual goal of finding optimal conditions for the desired outcome.

Defining the objective function

Defining the objective function is crucial because it describes what you are trying to optimize. Whether it's maximizing product yield, minimizing cost, or improving quality, a clear definition provides a roadmap for experimentation. For instance, in pharmaceuticals, the objective function could be the efficacy of a drug under varying pH levels and temperature.

Choosing a suitable design type

After clearly defining the objective, the next step involves choosing a suitable design type for the experiment. Two commonly used designs in RSM are the Central Composite Design (CCD) and the Box-Behnken Design (BBD). The CCD is highly efficient for exploring quadratic effects and is suitable for a larger number of factors, whereas the BBD is easier to execute as it often requires fewer experimental runs.

Performing the experiments

Setting up the laboratory and conducting experiments is where theories meet practice. Proper setup is essential to ensure that experiments are reproducible and that data is reliable. This stage involves detailed planning of every aspect of the experiment, including equipment calibration and method validation.

Analyzing data using RSM

Once experiments have been performed, the next step is to analyze the collected data using RSM techniques. This generally involves building response surface models to visualize the relationships between factors and responses. Tools and software such as R and MATLAB can facilitate this analysis, allowing users to assess the effectiveness of their designs and determine optimal conditions.

Advanced techniques in response surface optimization

For more complex optimization scenarios, advanced techniques in RSM can be highly beneficial. One notable approach is sequential experimentation, wherein initial experiments inform subsequent ones to refine the optimization process over time. This iterative process allows for greater adjustments based on findings, increasing the likelihood of achieving the desired outcome.

Multi-objective optimization is another advanced technique wherein multiple responses are balanced simultaneously. This approach can be particularly useful when trade-offs are required between competing objectives, such as cost versus quality. Finally, incorporating uncertainty into RSM using techniques like Monte Carlo simulations can enhance the robustness of the optimization process, making the outcomes more reliable in the face of inherent variability.

Practical examples of response surface optimization

Understanding theoretical concepts is one thing, but seeing how they translate to real-world applications offers invaluable insights. In pharmaceuticals, for instance, a case study might involve the optimization of a drug formulation by varying components like excipients and active pharmaceutical ingredients. By employing RSM, the formulation team can iteratively refine the mix to achieve the maximum therapeutic effect while minimizing side effects.

Case study: process optimization in manufacturing

In manufacturing, a similar example might entail optimizing a production line for component assembly. Utilizing RSM, engineers can model various assembly parameters—like speed, temperature, and pressure—to determine the optimal conditions that yield the highest quality product at the lowest cost. Insights gained from such studies not only drive efficiency but also inform future iterations of product manufacturing.

Best practices for implementing RSM

To maximize the benefits of RSM, it's essential to adopt best practices. First and foremost is collaborating with cross-functional teams. Engagement across diverse disciplines—be it chemistry, engineering, marketing, or quality assurance—ensures that all relevant perspectives contribute to the optimization strategy.

Additionally, maintaining a continuous improvement mindset through feedback loops can help refine response surfaces based on ongoing findings and adapt to new conditions. Lastly, thorough documentation and knowledge sharing are critical not just for transparency but for fostering learning and evolution within teams, making it easier for future projects to build on past experiences.

Exploring the future of response surface optimization

As technology continues to evolve, so do the methodologies around response surface optimization. The integration of artificial intelligence (AI) into RSM holds the potential to transform traditional optimization techniques. Machine learning algorithms can analyze vast datasets far more efficiently than humans, uncovering patterns and relationships that may not be immediately apparent.

Current trends indicate a growing industry adoption of RSM, particularly as manufacturers seek to become more adaptive in the face of fluctuating market demands and supply chain challenges. As more industries embrace data-driven decision-making, the integration of RSM with other modern methodologies will only prove vital for robust form optimization.

Additional considerations for using pdfFiller in document management

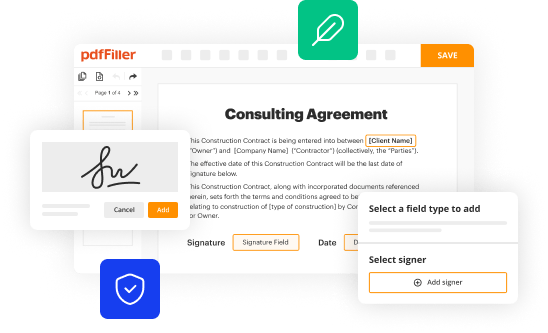

In the course of response surface optimization, effective document management is critical. pdfFiller provides a seamless solution for editing and collaborating on documents, making it a vital tool for teams engaged in optimization projects. With features allowing for easy modifications of forms and templates, pdfFiller streamlines the documentation processes associated with RSM.

eSigning and secure document handling

Security is paramount in maintaining the integrity of sensitive data. pdfFiller facilitates secure document handling and eSigning, ensuring that all modifications to forms are tracked, and signatures are securely verified. This capability is particularly useful during the iterative process of response surface optimization, where documentation often undergoes numerous revisions.

Interactive tools and resources

Utilizing effective tools can greatly enhance the efficiency of response surface optimization endeavors. pdfFiller offers customizable templates for response surface designs, making it easier for users to implement and manage experiments. These templates are not only user-friendly but also adaptable to specific project needs.

Sample calculation and analysis tools

Additionally, pdfFiller includes resources for sample calculation and analysis, which are essential for interpreting the results obtained from experiments. With built-in tools specifically designed for response surface analysis, users can streamline their processes for better decision-making and enhanced outcomes.

User testimonials and success stories

Many users of pdfFiller have shared transformative experiences highlighting how the platform has optimized their document workflows. From startups refining product presentations to large teams managing complex RSM projects, these testimonials reflect the tool's versatility and effectiveness in enhancing collaborative efficiencies and results.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I edit response surface optimization of on a smartphone?

How do I fill out the response surface optimization of form on my smartphone?

How do I complete response surface optimization of on an Android device?

What is response surface optimization of?

Who is required to file response surface optimization of?

How to fill out response surface optimization of?

What is the purpose of response surface optimization of?

What information must be reported on response surface optimization of?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.