Get the free article-interpreting-requirements-of-articles-500-516-of-nec ...

Get, Create, Make and Sign article-interpreting-requirements-of-articles-500-516-of-nec

Editing article-interpreting-requirements-of-articles-500-516-of-nec online

Uncompromising security for your PDF editing and eSignature needs

How to fill out article-interpreting-requirements-of-articles-500-516-of-nec

How to fill out article-interpreting-requirements-of-articles-500-516-of-nec

Who needs article-interpreting-requirements-of-articles-500-516-of-nec?

How to Interpret Requirements of Articles 500-516 of NEC Form

Understanding the NEC Form

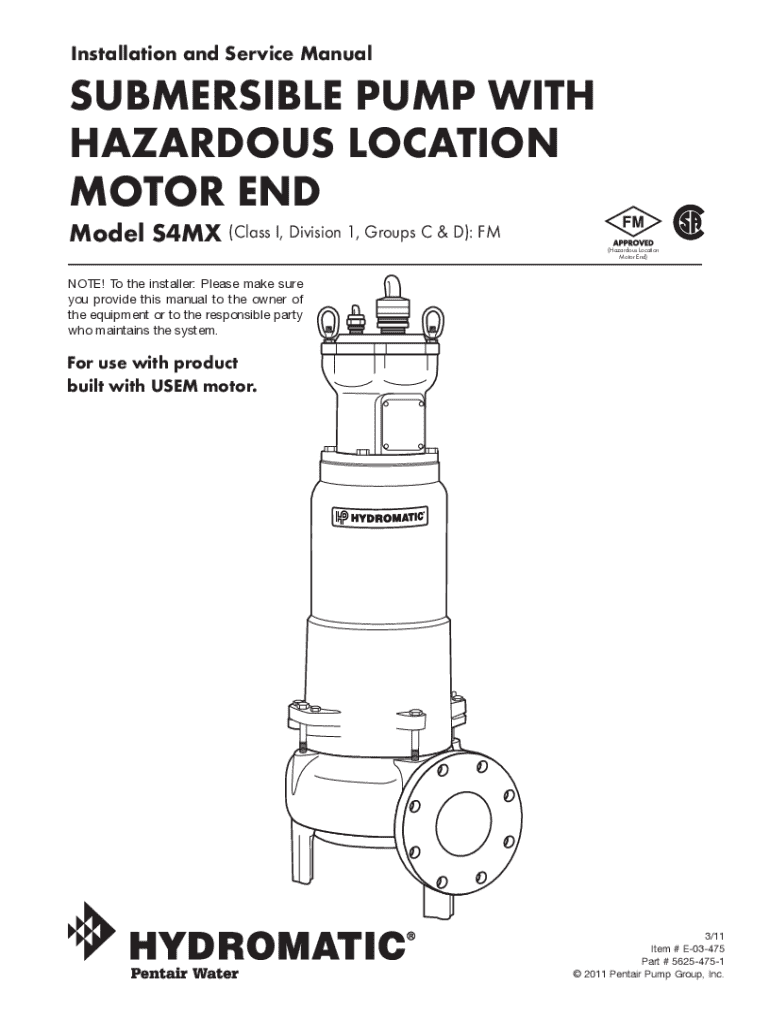

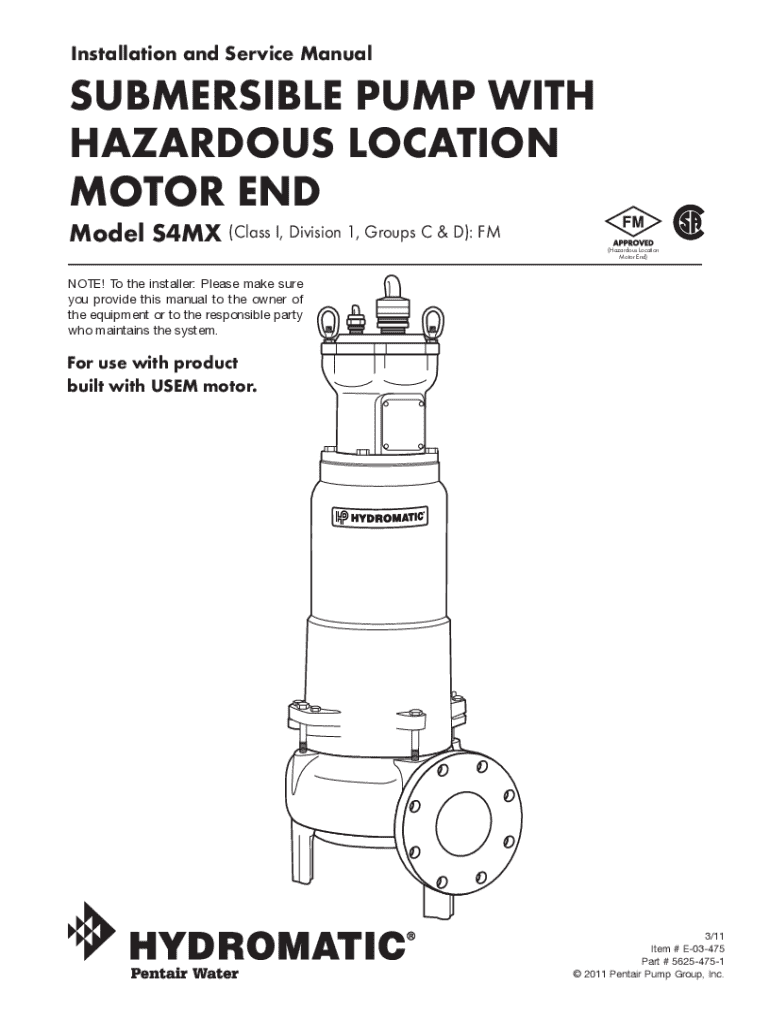

The NEC Form refers to the National Electrical Code, a comprehensive set of standards aimed at ensuring safe electrical installation and equipment use in various environments. Articles 500-516 specifically focus on hazardous locations, where the appropriate measures and regulations significantly contribute to electrical safety. Understanding these articles is crucial for professionals responsible for electrical installations in environments prone to explosions or fires caused by combustible dust, gases, or vapors.

Purpose of the Articles 500-516

Articles 500-516 serve to classify hazardous locations and outline the essential safety practices required in these areas. They detail how to assess the risks of various environments to determine the proper electrical equipment suitable for preventing dangerous incidents. These articles offer a structured approach to understanding the presence of hazardous materials and conditions, thus assuring compliance with safety regulations.

Breakdown of Articles 500-516

Diving deep into Articles 500-516 reveals essential standards for various hazardous classifications. Each article delineates specific requirements tailored to distinct types of hazards, ensuring that electrical systems operate safely and effectively within each environment.

Article 500: General requirements

Article 500 addresses the foundational understanding of hazardous locations. It defines what constitutes a hazardous location, classifying them into different types based on evidence of potential risks. These risk classifications help professionals assess and apply necessary precautions for each electrical installation.

Article 501: Class locations

Article 501 focuses on Class I locations, environments where flammable gases and vapors may be present in sufficient quantities to create explosive mixtures. This section elaborates on the techniques necessary for area classification, offering methods to accurately determine the degree of hazard. Appropriate selection and installation of equipment suitable for these classifications is critical to ensuring safety.

Article 502: Class locations

Class II locations, covered by Article 502, involve environments where combustible dusts are present. These can include manufacturing facilities, grain elevators, and chemical plants. This article details key considerations for electrical equipment installation, emphasizing the prevention of dust accumulation to minimize explosion risks.

Article 503: Class locations

Article 503 outlines the standards relevant to Class III locations, which involve the presence of easily ignitable fibers or flyings. Industries that process textiles, for example, fall under this classification. This article provides equipment specifications and safety requirements to reduce associated risks.

Articles 504-516: Specialized requirements

The remaining Articles from 504 to 516 deal with various specialized requirements corresponding to diverse classifications and divisions within hazardous locations. Each article provides specific criteria for installing electrical equipment, ensuring that all safety measures are addressed comprehensively.

Interpreting the requirements

Navigating the interpretation of Articles 500-516 requires a systematic approach to understand the inherent risks of electrical installations in various environments. Key factors for assessing risk include conducting a thorough analysis of the materials present, as well as evaluating historical and projected exposure duration and concentration levels.

Analyzing risk assessment

Assessing risks in hazardous locations involves comprehensive reviews of material types, their potential harm, and how they interact with electrical systems. Professionals must categorize the risks accurately to implement the correct safety measures. Regular updates to these assessments ensure ongoing compliance with NEC regulations.

Compliance strategies

To achieve compliance with NEC Articles 500-516, organizations should adopt a multi-faceted approach. Engaging with local authorities for interpretation and compliance guidelines is vital prior to beginning installations. Obtaining necessary permits and approvals ensures official backing for your compliance strategy.

Documentation and record keeping

Thorough documentation of compliance efforts is central to effective electrical safety management in hazardous locations. Recommended practices include maintaining detailed records of assessments, permits, and inspections to demonstrate adherence to NEC standards, thereby mitigating legal and operational risks.

Tools and resources for compliance

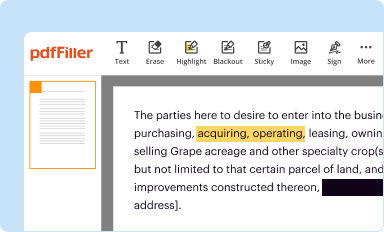

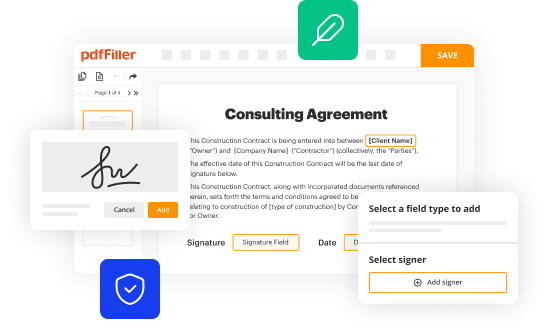

Ensuring compliance with Articles 500-516 can be streamlined through the utilization of various tools and resources. Utilizing document management solutions like pdfFiller, for example, can significantly enhance compliance documentation operations by allowing users to edit, fill out, and collaborate on NEC compliance documents seamlessly.

Utilizing PDF solutions for documentation

pdfFiller allows users to efficiently manage their NEC compliance documentation. The platform enables users to fill out and edit NEC forms conveniently, while its eSigning capabilities ensure official approvals can be secured swiftly and securely, thus optimizing the compliance process.

Interactive tools for hazard analysis

In addition to pdfFiller, various interactive tools and software facilitate hazard analysis. These resources allow professionals to compute hazard classifications and execute risk assessments more effectively, aligning them with NEC requirements.

Common challenges and how to overcome them

Electrical compliance in hazardous locations can lead to several challenges, often stemming from misinterpretation of NEC requirements. Addressing common misconceptions and pitfalls is essential for maintaining operational safety and regulatory adherence.

Misinterpretation of NEC requirements

One significant challenge lies in accurately interpreting NEC guidelines relevant to hazardous environments. Professionals should constantly update their knowledge and practice to circumvent these issues.

Collaborating with teams

Effective communication and collaboration within teams are pivotal for successful compliance with NEC regulations. Structuring regular meetings where team members can share insights and progress helps avert mistakes and ensures everyone is on the same page.

Final steps and best practices

As electrical installations progress in hazardous locations, the implementation of best practices is paramount. Professionals should consistently refer to detailed checklists and outlines to ensure all safety practices are followed and any potential risks are mitigated.

Implementation of best practices in hazardous locations

A checklist can serve as an invaluable tool in ensuring every aspect of installations adheres to safety standards. Frequently validating all installations through inspections can minimize risks associated with hazardous locations.

Resources for continued learning

To stay ahead in compliance, ongoing education is crucial. Industry associations and platforms offering training can provide updates on NEC changes and advancements.

Case studies: Successful compliance applications

Real-world examples of compliance with NEC regulations can serve as a guide for professionals navigating hazardous environments. Various industries have successfully implemented NEC Articles 500-516 and have valuable insights to share.

Real-world examples of NEC compliance

These examples illustrate how certain companies have adapted their processes to meet NEC requirements while enhancing workplace safety. By analyzing these case studies, professionals can extract key learnings and apply successful strategies in their unique environments.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I make changes in article-interpreting-requirements-of-articles-500-516-of-nec?

Can I create an eSignature for the article-interpreting-requirements-of-articles-500-516-of-nec in Gmail?

How do I fill out the article-interpreting-requirements-of-articles-500-516-of-nec form on my smartphone?

What is article-interpreting-requirements-of-articles-500-516-of-nec?

Who is required to file article-interpreting-requirements-of-articles-500-516-of-nec?

How to fill out article-interpreting-requirements-of-articles-500-516-of-nec?

What is the purpose of article-interpreting-requirements-of-articles-500-516-of-nec?

What information must be reported on article-interpreting-requirements-of-articles-500-516-of-nec?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.