Get the free A Series Internal Combustion Truck

Get, Create, Make and Sign a series internal combustion

Editing a series internal combustion online

Uncompromising security for your PDF editing and eSignature needs

How to fill out a series internal combustion

How to fill out a series internal combustion

Who needs a series internal combustion?

A comprehensive guide to a series internal combustion form

Internal combustion engine fundamentals

An internal combustion engine (ICE) converts fuel into mechanical energy by burning a mixture of fuel and air within a combustion chamber. The operation of these engines is largely dictated by two central cycles: the two-stroke and the four-stroke. The two-stroke cycle completes a power cycle in two strokes of the piston, which allows for lighter designs suited for smaller applications. Conversely, the four-stroke cycle involves four distinct strokes of the piston—intake, compression, power, and exhaust—which improves fuel efficiency and creates a more stable power delivery.

There are two primary forms of ignition in ICEs: spark ignition and compression ignition. Spark ignition engines, such as gasoline engines, utilize a spark plug to ignite the air-fuel mixture, while compression ignition engines, primarily diesel engines, compress air to such an extent that the heat generated ignites the fuel. The components that make up these engines include the cylinder, piston, crankshaft, and the fuel system, each playing critical roles in engine performance and longevity.

Types of internal combustion engines

Internal combustion engines can be broadly classified into reciprocating engines and rotary engines. Reciprocating engines, which include most car and truck engines, operate based on the linear motion of pistons that convert the energy from combustion into mechanical work. These engines are widely used in a plethora of applications ranging from automobiles to aviation, owing to their design simplicity and effectiveness.

In contrast, rotary engines, such as Wankel engines, use a triangular rotor to create chambers for combustion. This design minimizes the number of moving parts, offering advantages in terms of weight and smoothness of operation but often compromises on fuel efficiency and emissions. Lastly, combustion turbines, which are distinct from the former types, are designed for continuous power generation and are broadly utilized in power plants and aircraft propulsion.

Fuel and oxidizer considerations

The type of fuel used in an internal combustion engine significantly influences its design and performance. Traditional fuels like gasoline and diesel have distinct combustion properties, with gasoline engines generally producing higher power outputs while diesel engines offer better fuel efficiency. Additionally, alternative fuels such as ethanol and biodiesel are gaining popularity due to their renewable nature and lower emissions.

The oxidizer, typically air, plays a crucial role in the combustion process. The proper balance between fuel and oxidizer is essential for achieving optimal combustion efficiency and reducing harmful emissions. Various additives may also be used to enhance combustion, and understanding these components' roles is vital for anyone working with internal combustion engines.

Measuring engine performance

Understanding how to measure the performance of internal combustion engines is crucial for optimizing their efficiency and power output. Key performance metrics include horsepower and torque, which are essential for assessing engine capability. Horsepower indicates the engine's ability to perform work over time, while torque reflects the rotational force available at the engine's output.

Fuel efficiency ratings, typically expressed in miles per gallon (MPG) or litres per 100 km, help gauge the performance of an engine concerning fuel consumption. Performance testing methods, such as using dynamometers, allow for precise measurement of these metrics under various conditions. Real-world driving analyses can also serve as important indicators of how well an engine performs outside laboratory settings.

Combustion processes and enhancements

The combustion process in an internal combustion engine involves complex chemical reactions that convert fuel into heat and mechanical energy. These processes can typically be divided into several stages: ignition, combustion, and expansion. Understanding these stages helps engineers develop engines that maximize efficiency and performance, ensuring that the chemical energy stored in fuel is effectively converted into mechanical work.

Enhancements such as forced induction (e.g., turbocharging and supercharging) improve engine power by forcing more air into the combustion chamber, allowing for more fuel to be burned. Additionally, features like variable valve timing adjust the timing of valve openings and closings, optimizing engine performance across a range of speeds. Strategies for combustion optimization often involve fine-tuning the air-fuel mixture and utilizing advanced ignition systems to ensure complete combustion.

Impact on environment

Internal combustion engines are significant contributors to air pollution, emitting greenhouse gases like carbon dioxide, nitrogen oxides, and particulate matter. These emissions can result in severe environmental impacts, contributing to global warming and health-related concerns. Awareness of these impacts has prompted actions to develop cleaner engine technologies and alternative fuels that reduce reliance on fossil fuels.

Efforts to mitigate emissions often focus on improving engine efficiency and adopting after-treatment solutions, such as catalytic converters and particulate filters. Noise pollution is another concern associated with internal combustion engines. Engine designs can include noise-reduction technologies such as mufflers and soundproofing materials to mitigate the sounds produced during operation.

Technological innovations in internal combustion engines

Emerging technologies in the realm of internal combustion engines have risen to meet the challenge of reducing emissions while improving performance. Hybridization is one of the most notable innovations, where electric motors work in tandem with traditional engines to enhance fuel efficiency and reduce carbon output. Turbocharging advancements have also become popular, offering the ability to increase the power output of smaller engines while maintaining higher fuel efficiency.

The future of internal combustion engines is likely to see a substantial shift in design and fuel sources. Increased research into hydrogen fuel cells and other sustainable fuels could redefine engine expectations. Automakers are developing technologies that integrate digital tools for real-time monitoring and management, paving the way for more intelligent vehicles that optimize engine performance based on driving conditions and user behavior.

Maintenance and management of internal combustion engines

To ensure optimal performance and longevity, regular maintenance of internal combustion engines is essential. Routine practices include oil changes and filter replacements, crucial for maintaining clean engine components and preventing wear. Scheduled inspections can identify emerging issues before they escalate into significant problems, ensuring the engine operates at its peak efficiency.

Common issues for internal combustion engines include knocking, which may indicate problems with ignition timing or fuel quality, and poor fuel economy resulting from various factors including air-fuel ratio imbalances or worn components. Proper troubleshooting requires understanding of engine basics, allowing drivers and technicians to address issues promptly and effectively.

Interactive tools for engine management

Advancements in technology have made digital platforms increasingly valuable for managing and diagnosing internal combustion engines. App-based interfaces allow users to monitor engine performance in real-time, offering insights into performance metrics and potential issues. These tools provide a comprehensive understanding of how an engine is performing, alerting users to irregularities promptly.

Data visualization tools that track performance over time can aid in making data-driven decisions for maintenance and upgrades. Online forums and communities foster collaboration among engine enthusiasts and professionals, providing valuable insights and troubleshooting tips. Alongside, platforms like pdfFiller enhance documentation management for engine-related projects, streamlining processes like signing and editing essential documents.

Document management for internal combustion engines

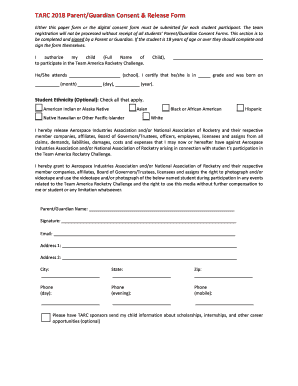

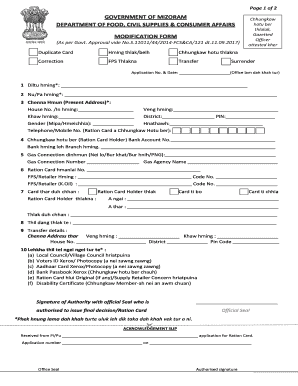

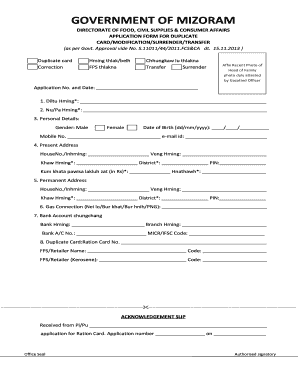

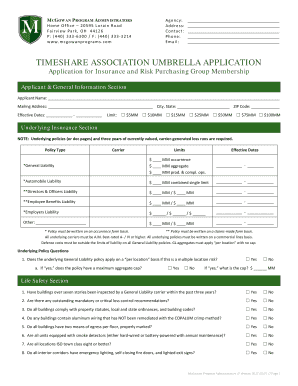

Effective document management is essential for ensuring that all aspects of maintaining internal combustion engines are organized and accessible. Essential documentation includes user manuals, service records, and compliance documentation that ensure adherence to emissions regulations. Keeping accurate and updated records not only aids in maintenance but also serves to provide audit trails in case of environmental assessments.

Leveraging tools like pdfFiller allows users to edit and sign important documents seamlessly. With a cloud-based platform, access is granted from anywhere, simplifying the management of sensitive engine-related paperwork. This not only enhances efficiency but also encourages collaboration among team members who need to work on engine projects together.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send a series internal combustion for eSignature?

How do I make changes in a series internal combustion?

How do I edit a series internal combustion in Chrome?

What is a series internal combustion?

Who is required to file a series internal combustion?

How to fill out a series internal combustion?

What is the purpose of a series internal combustion?

What information must be reported on a series internal combustion?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.