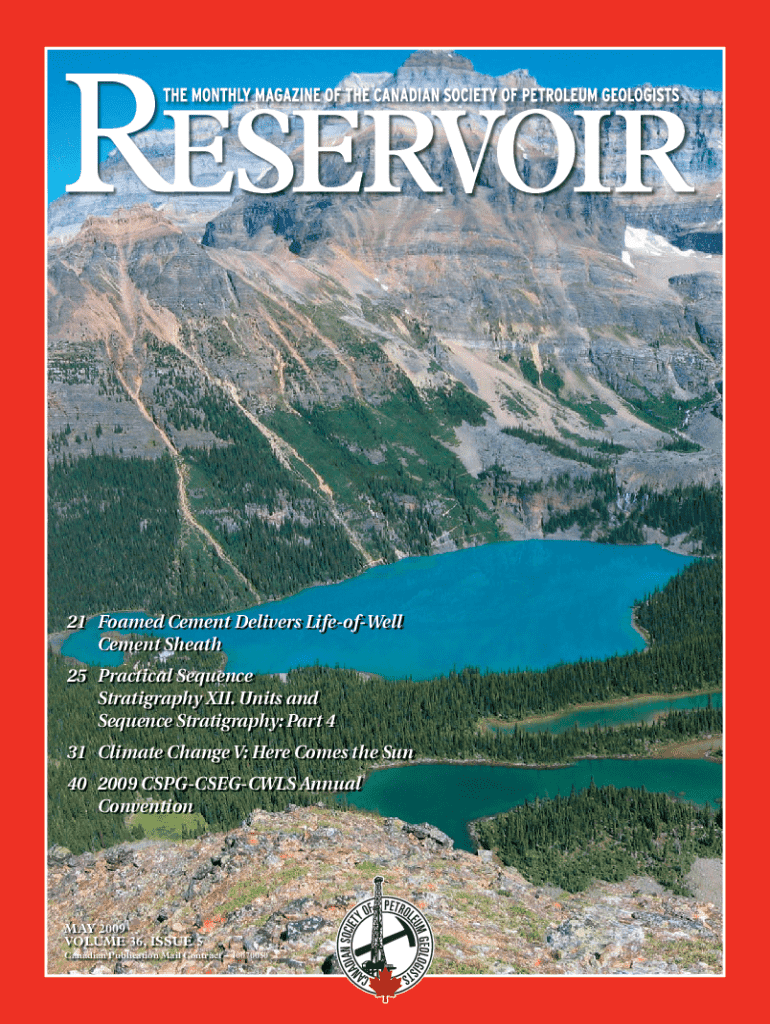

Get the free 21Foamed Cement Delivers Life-of-Well

Get, Create, Make and Sign 21foamed cement delivers life-of-well

Editing 21foamed cement delivers life-of-well online

Uncompromising security for your PDF editing and eSignature needs

How to fill out 21foamed cement delivers life-of-well

How to fill out 21foamed cement delivers life-of-well

Who needs 21foamed cement delivers life-of-well?

21foamed cement delivers life-of-well form

Overview of foamed cement and its applications

Foamed cement is an innovative construction material that incorporates air bubbles into the cement mixture, resulting in a lightweight and versatile product. This aerated blend not only reduces the overall weight of the structure but enhances its insulating properties and fire resistance. Typically, foamed cement is utilized in various applications, including thermal insulation, filling voids, and as a lightweight concrete for construction projects. The significance of incorporating life-of-well forms cannot be overstated, especially in ensuring structural integrity and durability over the lifespan of a project.

Understanding the life-of-well form

A life-of-well form refers to the structural framework designed to ensure the long-term stability and efficiency of various installations, such as pipelines, wells, or foundations. Properly designed life-of-well forms facilitate maintenance, enhance protection against environmental conditions, and optimize operational functionality. By leveraging appropriate materials like 21foamed cement, project managers can significantly reduce project risks, leading to lower costs and increased trust in the efficacy of the construction.

The advantages offered by life-of-well forms include:

Several projects have successfully implemented life-of-well forms using foamed cement, showcasing its effectiveness in various environments, including regions susceptible to geological instability.

Advantages of using 21foamed cement

One of the standout features of 21foamed cement is its lightweight nature, making it easier to handle and apply across different projects. This property translates directly into lower transportation costs and simplified onsite logistics. Additionally, the enhanced thermal insulation and fire resistance offered by 21foamed cement contribute to the safety and efficiency of structures, ensuring they meet necessary regulations and standards.

Moreover, the environment-friendly aspects of 21foamed cement cannot be overlooked. As it reduces the volume of raw materials needed and lowers carbon footprints during production, it aligns with present-day sustainability goals. Further, when compared to traditional materials, 21foamed cement often proves to be more cost-effective, particularly when factoring in its life-cycle performance and reduced maintenance needs.

Technical specifications

Understanding the specific composition of 21foamed cement is crucial for maximizing its application potential. The mixture typically includes specialized binders and foaming agents that ensure consistent quality and desired performance metrics. For instance, the density of 21foamed cement usually ranges from 500 to 1600 kg/m³, and it can endure compressive strengths from 1.5 to 5 MPa depending on the intended use.

In terms of performance characteristics, 21foamed cement exhibits minimal shrinkage, which is vital for maintaining structural integrity, and provides impressive thermal conductivity ratings between 0.09 and 0.20 W/mK, showcasing its efficacy in thermal insulation applications.

Preparation and application process

Preparing and applying 21foamed cement can be highly efficient when following a systematic approach. Start with gathering the necessary materials, which generally include a high-quality cement binder, foaming agent, water, and any required additives. Pay close attention to the quality specifications of each component to ensure successful mixing and application.

### Mixing instructions

### Application methods for creating life-of-well forms

Interactive tools and resources

For those looking to dive deeper into the application of 21foamed cement, interactive tools can streamline the planning and execution phases. Users can take advantage of online calculators that assist with material requirements and provide cost estimations tailored to specific projects. Additionally, pdfFiller offers templates for documentation related to life-of-well forms, empowering users to maintain organized records throughout their project lifecycle.

Furthermore, downloadable guides detailing proper mixing and application techniques can bolster understanding, especially for newcomers to the construction field. These resources collectively contribute to successful project outcomes.

Maintenance of life-of-well forms using 21foamed cement

The expected lifespan of life-of-well forms made with 21foamed cement can extend several decades, provided they are properly maintained. Routine inspections are crucial for identifying potential issues before they escalate. Key considerations for maintenance include checking for cracks, observing signs of moisture intrusion, and ensuring structural components remain intact.

In terms of environmental considerations, users should be mindful of local regulations and standards for repairs, ensuring materials used are compatible with 21foamed cement to maintain overall integrity and performance. Regularly addressing maintenance needs can significantly prolong the usable life of these forms.

Case studies: successful life-of-well applications with 21foamed cement

Several notable projects have effectively utilized 21foamed cement to create life-of-well forms that stand as testimonies to its potential. For instance, a recent energy project in Texas implemented 21foamed cement as part of its infrastructure, aimed at bolstering stability against both seismic and climatic pressures.

### Key project details

User guide: managing your documentations with pdfFiller

As projects involving 21foamed cement require extensive documentation, utilizing pdfFiller can significantly enhance document management. Users can efficiently fill out, edit, and sign forms related to 21foamed cement from the convenience of a cloud-based platform, accessible anywhere with Internet connectivity.

### Features to leverage include:

Frequently asked questions

When considering 21foamed cement and life-of-well forms, users may have a variety of questions. Common queries involve the best practices for application, expected costs, and troubleshooting common issues that might arise during the mixing or curing process.

### Common troubleshooting tips include:

Insights on future trends in foamed cement use

The evolution of foamed cement technology suggests exciting future prospects. Innovations in materials science are likely to lead to enhanced product formulations that can further increase performance metrics. As construction projects increasingly embrace sustainability, the demand for eco-friendly solutions like 21foamed cement is projected to surge.

Moreover, emerging technologies such as advanced monitoring systems will likely impact project management by incorporating real-time data analysis, thus optimizing the application of materials. These trends could revolutionize how teams approach challenges in construction, allowing a more proactive rather than reactive methodology.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I manage my 21foamed cement delivers life-of-well directly from Gmail?

How do I fill out 21foamed cement delivers life-of-well using my mobile device?

How do I edit 21foamed cement delivers life-of-well on an iOS device?

What is 21foamed cement delivers life-of-well?

Who is required to file 21foamed cement delivers life-of-well?

How to fill out 21foamed cement delivers life-of-well?

What is the purpose of 21foamed cement delivers life-of-well?

What information must be reported on 21foamed cement delivers life-of-well?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.