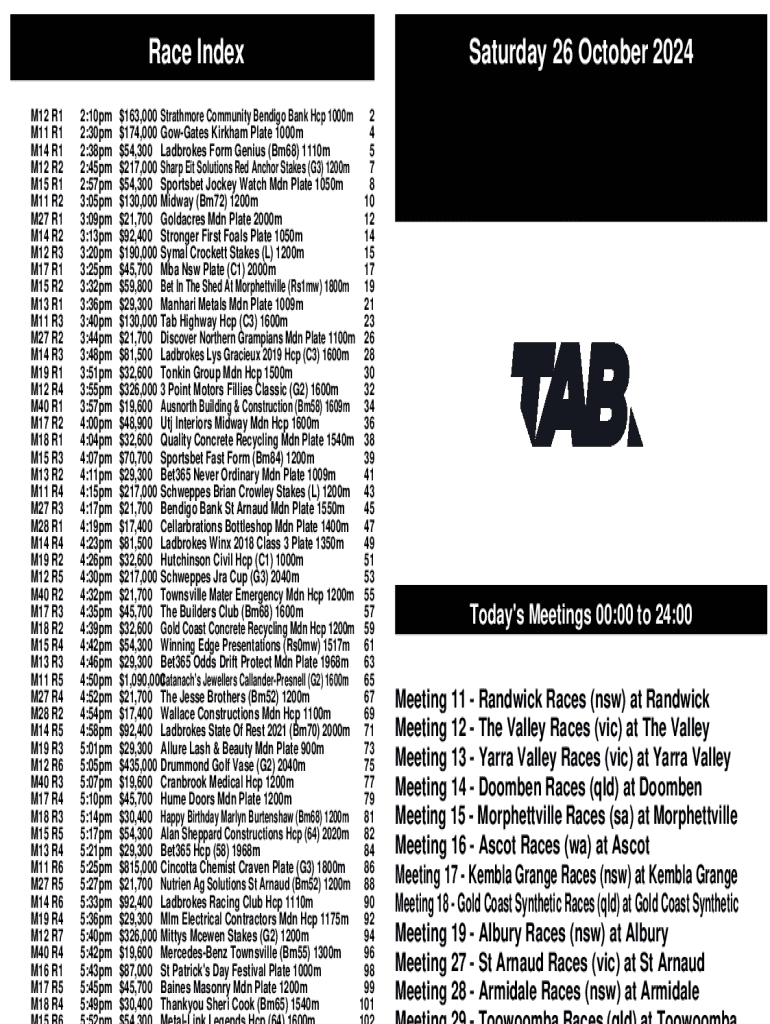

Get the free Hydraulic Filtration & Contamination Control Products

Get, Create, Make and Sign hydraulic filtration amp contamination

How to edit hydraulic filtration amp contamination online

Uncompromising security for your PDF editing and eSignature needs

How to fill out hydraulic filtration amp contamination

How to fill out hydraulic filtration amp contamination

Who needs hydraulic filtration amp contamination?

Hydraulic Filtration and Contamination Form How-to Guide

Understanding hydraulic filtration

Hydraulic filtration is a critical process in hydraulic systems, ensuring that the hydraulic fluid remains clean and free from particles that could disrupt system performance. By removing contaminants from the hydraulic fluid, hydraulic filtration enhances operational efficiency, prolongs equipment life, and reduces the likelihood of failure. Contamination control is paramount in hydraulic systems since even minor impurities can lead to significant operational issues.

There are three primary types of contaminants commonly found in hydraulic fluids: solid, liquid, and gaseous. Solid contaminants, such as dirt and metal shavings, represent the bulk of contaminants and can cause wear and tear on vital components. Liquid contaminants include water and other fluids that may mix with hydraulic oil, affecting its lubricating properties. Gaseous contaminants, primarily air, can lead to cavitation and reduced system pressure, hindering the hydraulic system’s effectiveness.

The role of hydraulic filtration systems

Hydraulic filtration systems play a pivotal role in maintaining the cleanliness of hydraulic fluids and safeguarding the integrity of hydraulic systems. These systems are designed to trap contaminants before they can enter the machinery, ensuring efficient operation. The key components of filtration systems include filter elements, housings, and various accessories that facilitate effective contamination removal.

There are several types of hydraulic filters, each suited for different applications within hydraulic systems. Inline filters work within the fluid line, offering real-time filtration, while return line filters clean fluid returning to the reservoir, thus ensuring that only clean fluid re-enters the system. Pressure filters operate under system pressure to maintain optimal filtration under load, preventing backflow of contaminants.

Importance of accurate filtration documentation

Proper documentation in hydraulic filtration is essential, and utilizing a hydraulic filtration contamination form is vital for tracking contamination levels and maintenance history. This standardized form helps operators and maintenance teams effectively monitor the cleanliness of hydraulic fluids, facilitating timely maintenance and reducing operational downtime. The process of routine documentation empowers organizations to maintain compliance with industry standards and best practices.

Benefits of using a hydraulic filtration contamination form include the ability to track contamination levels accurately, schedule necessary maintenance, and provide consistency in information across different teams. Well-maintained records enable predictive maintenance, allowing teams to foresee potential issues before they escalate into costly repairs.

Filling out the hydraulic filtration contamination form

Completing a hydraulic filtration contamination form can seem daunting, but it is a straightforward process when approached systematically. Start with gathering required information, such as equipment details and specifics of the hydraulic fluid being used. This foundational data is crucial for accurate documentation.

Accuracy is essential when filling out the form. To ensure this, double-check all measurements and use clear, concise language throughout. Clarity in documentation facilitates better communication among team members and mitigates misunderstandings.

Editing and customizing the form

The hydraulic filtration contamination form can be tailored to fit the specific needs of your organization using pdfFiller. Accessing the template online is user-friendly, with intuitive tools that allow for document alteration without extensive training.

Customizing the form enhances its relevance to your operational processes, making it a functional tool for daily use.

Utilizing interactive tools for improved filtration management

pdfFiller offers various interactive tools that can greatly enhance filtration management. These tools not only streamline document creation but also foster collaboration among team members working on hydraulic operations. The cloud-based document management system means that documents can be accessed from any location, allowing for greater flexibility in handling critical information.

With these capabilities, pdfFiller empowers teams to work smarter, ensuring optimal filtration management through improved documentation and collaboration.

Ensuring compliance and best practices

To maintain optimal hydraulic system performance, understanding and adhering to industry regulations surrounding hydraulic filtration is imperative. Regular audits of filtration systems are a proactive measure to ensure compliance and guarantee that systems operate within prescribed standards. Documenting these audits using the hydraulic filtration contamination form supports compliance efforts and aids in regulatory checks.

Fostering a culture of compliance and best practices within teams significantly contributes to improved operational efficiency and lower downtimes due to filtration issues.

Troubleshooting common issues in hydraulic filtration

Identifying signs of contamination issues early can save time and resources in hydraulic systems. Typical indicators include unusual noise, fluctuating pressure, and uncharacteristic system temperature changes. Prompt action is crucial when filtration systems indicate a problem; monitoring contamination levels using the hydraulic filtration contamination form allows for rapid response.

Proactive management of contamination issues leads to increased reliability in hydraulic systems and allows quicker restoration of normal operations.

Related products and recommendations

Choosing the right filters and equipment plays a vital role in the efficacy of hydraulic filtration. Various filter types and brands cater to different needs, so selecting the appropriate models is essential for system health. From inline filters to pressure filters, finding the correct match for your applications is necessary for optimum performance.

Leveraging the right products and technology aids in maintaining optimal filtration standards and enhances overall system performance.

FAQs about hydraulic filtration

Many individuals seek clarity on hydraulic filtration and contamination management. Common questions typically revolve around how often to change filters, the industry standards for fluid cleanliness, and best practices for documenting any changes. Addressing these inquiries aids in forming sound operational strategies and improving filtration processes.

By understanding these nuances, teams can improve hydraulic system management and reinforce a culture of cleanliness.

Exploring further learning opportunities

Individuals aiming to deepen their understanding of hydraulic filtration have access to various learning resources, including webinars and online courses. These platforms provide valuable insights into emerging best practices and technologies in hydraulic filtration. Engaging with these educational opportunities helps operational teams stay ahead in maintaining hydraulic systems effectively.

These resources empower teams and individuals to enhance their operational capabilities, positioning them for success in a competitive industry landscape.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I edit hydraulic filtration amp contamination from Google Drive?

How can I send hydraulic filtration amp contamination for eSignature?

How do I fill out the hydraulic filtration amp contamination form on my smartphone?

What is hydraulic filtration amp contamination?

Who is required to file hydraulic filtration amp contamination?

How to fill out hydraulic filtration amp contamination?

What is the purpose of hydraulic filtration amp contamination?

What information must be reported on hydraulic filtration amp contamination?

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.