Get the free Quality Check Process template

Show details

Quality Check Process

We are not affiliated with any brand or entity on this form

Why choose pdfFiller for your legal forms?

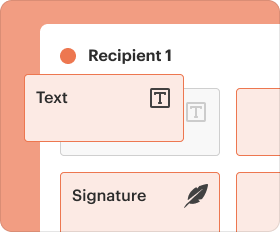

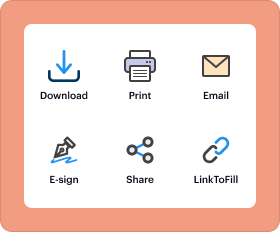

All-in-one solution

pdfFiller offers a PDF editor, eSignatures, file sharing, collaboration tools, and secure storage—all in one place.

Easy to use

pdfFiller is simple, cloud-based, has a mobile app, and requires no downloads or a steep learning curve.

Secure and compliant

With encryption, user authentication, and certifications like HIPAA, SOC 2 Type II, and PCI DSS, pdfFiller keeps sensitive legal forms secure.

What is quality check process

The quality check process is a systematic evaluation to ensure that products or services meet specified standards and requirements.

pdfFiller scores top ratings on review platforms

This page resolved my issue. Great to use it.

love it fast

If I had the option to put 100 stars, I would. This product is fantastic. There are small issues with reformatting, but I think the user can get over that.

very quick and learning process

Very helpful in finding documents related to importing to the US

Typing is easier to read than handwriting.

Who needs quality check process template?

Explore how professionals across industries use pdfFiller.

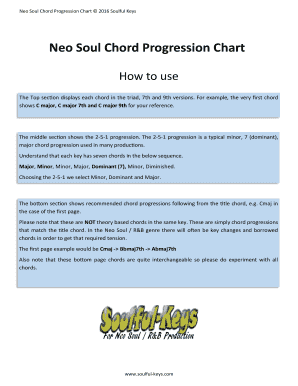

Quality Check Process Guide

What is the quality check process?

Understanding the quality check process is essential for effective quality control in production. Quality control is a systematic approach to ensuring that a product meets specified quality standards. The classic quality control framework includes the four steps: Plan, Do, Check, Act (PDCA). Maintaining high-quality standards not only enhances customer satisfaction but also contributes to the overall success of a business.

What is the purpose of a quality check process form?

A quality check process form serves several important purposes in a production environment. Its primary function is to aid in systematic documentation, making it easier to track product quality over time. The form also plays a crucial role in ensuring compliance with industry standards, which is vital for maintaining market credibility and avoiding regulatory penalties.

How do you define necessary quality parameters?

Defining necessary quality parameters is fundamental to effective quality checks. This involves creating a comprehensive list of essential quality metrics that will be included on the quality check process form. Identifying relevant quality parameters typically requires collaboration with multiple stakeholders in production, as it varies widely among industries—from manufacturing to food services.

-

The ability of a product to withstand wear, pressure, or damage over time.

-

The degree to which a product's measurements conform to specified requirements.

-

Visual or tactile attributes that meet customer expectations.

-

The consistency with which a product performs its intended function.

What essential fields should be included on the form?

A well-designed quality check process form should include several essential fields that facilitate effective quality assessments. Key identification fields such as product batch number and date of production are critical for traceability. Additionally, a space for product descriptions and specific quality metrics allows for thorough inspections and clearly documented results.

-

An identifier for the specific batch of product being inspected.

-

When the product was manufactured or packaged.

-

Defined metrics against which the product quality is assessed.

-

A section for recording whether the product passed or failed the inspection.

How to design an effective quality check form layout?

Creating an intuitive and user-friendly layout for a quality check process form enhances usability and reduces errors. Start by incorporating clear headings and adequate space for remarks and observations, which allows inspectors to add context to their findings. Leveraging interactive tools available on platforms like pdfFiller can significantly streamline the form design process, making compliance easier.

Why is reviewing inspection and testing results important?

The process of analyzing testing data from quality checks is vital for driving continuous improvement within an organization. By logging outcomes and documenting results for future reference, businesses can identify trends and areas needing adjustment. Using a checklist format simplifies inspection reviews and helps maintain a consistent evaluation process across different teams.

What actions should be taken based on quality control insights?

Proactive changes based on feedback from quality checks are crucial for fostering a culture of continuous improvement. Documenting corrective actions taken in response to quality issues ensures accountability and aids in future inspections. Such insights gained from the quality check process form can drive better decision-making and enhance product quality.

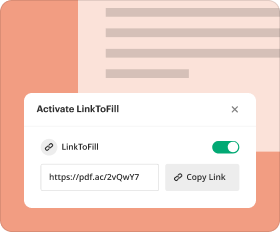

How can you enhance collaboration through pdfFiller?

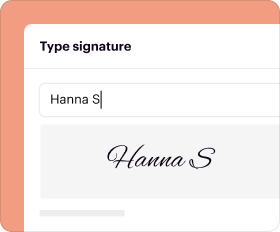

Utilizing pdfFiller's collaborative features can significantly enhance the quality check process. Best practices for sharing and managing the quality check process form are essential for effective teamwork. Furthermore, integrating eSignature functionalities allows for quick approvals from stakeholders, streamlining operations, and maintaining compliance.

How to fill out the quality check process template

-

1.Open pdfFiller and log in to your account or create a new one if necessary.

-

2.Upload the quality check process document you need to fill out by clicking 'Upload' and selecting the file from your computer.

-

3.Once the file is uploaded, use the 'Edit' option to access various editing tools.

-

4.Locate the fields in the document that require input; these may include product details, inspection results, and responsible personnel.

-

5.Fill in the required information clearly and accurately, ensuring that all data fields are completed as per your company’s quality standards.

-

6.Review the filled-out document for any errors or omissions to ensure completeness.

-

7.Once reviewed, you can save the document or use the 'Send' feature to share it directly with relevant stakeholders for further processing.

-

8.Consider using the 'Sign' feature if approvals are required after the quality checks are completed.

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.