Anneal Required Field For Free

Drop document here to upload

Up to 100 MB for PDF and up to 25 MB for DOC, DOCX, RTF, PPT, PPTX, JPEG, PNG, JFIF, XLS, XLSX or TXT

Note: Integration described on this webpage may temporarily not be available.

0

Forms filled

0

Forms signed

0

Forms sent

Discover the simplicity of processing PDFs online

Upload your document in seconds

Fill out, edit, or eSign your PDF hassle-free

Download, export, or share your edited file instantly

Top-rated PDF software recognized for its ease of use, powerful features, and impeccable support

Every PDF tool you need to get documents done paper-free

Create & edit PDFs

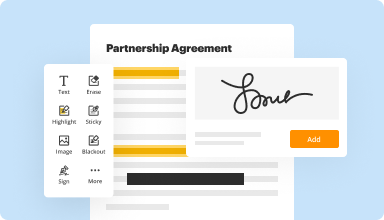

Generate new PDFs from scratch or transform existing documents into reusable templates. Type anywhere on a PDF, rewrite original PDF content, insert images or graphics, redact sensitive details, and highlight important information using an intuitive online editor.

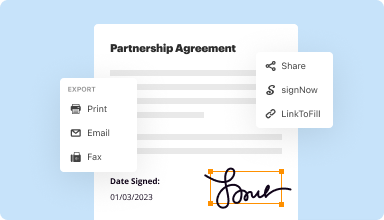

Fill out & sign PDF forms

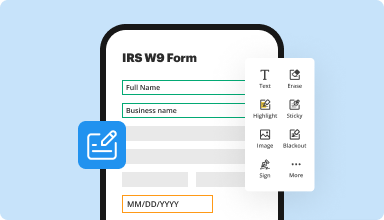

Say goodbye to error-prone manual hassles. Complete any PDF document electronically – even while on the go. Pre-fill multiple PDFs simultaneously or extract responses from completed forms with ease.

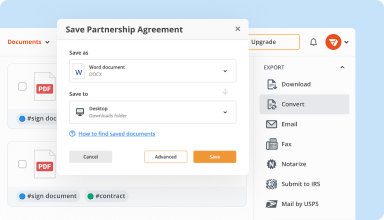

Organize & convert PDFs

Add, remove, or rearrange pages inside your PDFs in seconds. Create new documents by merging or splitting PDFs. Instantly convert edited files to various formats when you download or export them.

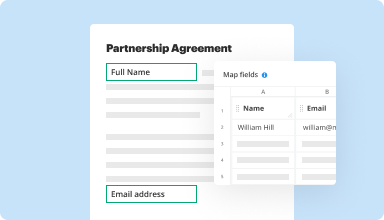

Collect data and approvals

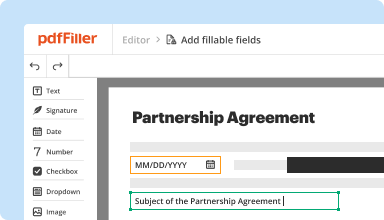

Transform static documents into interactive fillable forms by dragging and dropping various types of fillable fields on your PDFs. Publish these forms on websites or share them via a direct link to capture data, collect signatures, and request payments.

Export documents with ease

Share, email, print, fax, or download edited documents in just a few clicks. Quickly export and import documents from popular cloud storage services like Google Drive, Box, and Dropbox.

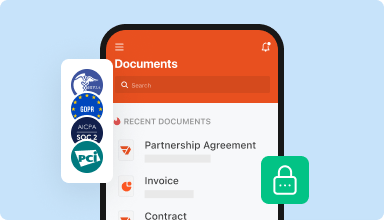

Store documents safely

Store an unlimited number of documents and templates securely in the cloud and access them from any location or device. Add an extra level of protection to documents by locking them with a password, placing them in encrypted folders, or requesting user authentication.

Customer trust by the numbers

64M+

users worldwide

4.6/5

average user rating

4M

PDFs edited per month

9 min

average to create and edit a PDF

Join 64+ million people using paperless workflows to drive productivity and cut costs

Why choose our PDF solution?

Cloud-native PDF editor

Access powerful PDF tools, as well as your documents and templates, from anywhere. No installation needed.

Top-rated for ease of use

Create, edit, and fill out PDF documents faster with an intuitive UI that only takes minutes to master.

Industry-leading customer service

Enjoy peace of mind with an award-winning customer support team always within reach.

What our customers say about pdfFiller

See for yourself by reading reviews on the most popular resources:

I am very happy with the service. It is easy to use and very versatile. It is, however, quite expensive for the annual plan. Even if I used this on a daily basis, I'd feel like50 a year is much more reasonable.

2015-08-18

filling our immigration docs that were not savable and this app totally helped me to save them and get back to the docs when I have more info. Awesome. One recommendation: I would like to be able to save to a specific file in my computer rather than have to move from the download file :-)

2017-07-23

It was very good. However, I would be interested in the webinar because I have not figured out how to download a document from another site to my account as I was advised by the support person.

2017-12-15

The obne drawback I find is when I am typing into a field there is no auto return and I suddenly am skipping to other fields. However, it is still a pretty good product.

2018-09-25

I needed to urgently get some documents compressed and I found this online and went on basic plan . The team support was very helpful . This is a very effective tool for all documentation work

2023-09-11

I enjoyed using PdfFiller as It's…

I enjoyed using PdfFiller as It's usually difficult to edit PDFs. But with this site I could do it well. Will definitely keep on using it.

2022-07-06

I made a mistake and accidentally…

I made a mistake and accidentally signed up for this service. When I got the bill for $96, I was shocked. I thought it was going to be such a hassle and was so pleasantly surprised. I got a full refund within an hour of writing to them with a very nice note.

2021-08-10

PDF Filler was very helpful preparing the documents. Questions were answered by the staff VERY PROMPTLY. I appreciate the assistance and directions to the questions I had.

2021-03-04

pdfFiller is user-friendly and the site is easy to...

pdfFiller is user-friendly and the site is easy to navigate. I love the fact that a function stays the same until you change it, eg. a font size and format. However, I would like the option to use all the Fonts that I have installed on my own computer. When a page is duplicated, I'd love it if the 'changes' made to the original using pdfFiller, could also be duplicated rather than simply a duplication of the original document. I also can't seem to find a way to cut and paste text to apply it in a different area of the document, which means that the process of replicating a change is more time-consuming, but this could be my current unfamiliarity with the software. I was impressed that within a couple of hours of use, I was offered the option to attend a webinar to improve my understanding.

2020-07-20

How-to Guide

How to edit a PDF document using the pdfFiller editor:

01

Drag & drop your document to the uploading pane on the top of the page

02

Choose the Anneal Required Field feature in the editor's menu

03

Make all the required edits to your file

04

Click the “Done" orange button at the top right corner

05

Rename your file if required

06

Print, share or download the template to your computer

Anneal Required Field Feature Description

The Anneal Required Field feature simplifies the process of managing essential data inputs. With this feature, you can easily specify fields that must be completed, ensuring that your data collection is accurate and complete. This tool is designed to help you maintain the integrity of your data while streamlining your operations.

Key Features

Identify mandatory fields to ensure users complete critical information

Integrate seamlessly with existing data collection systems

Provide real-time validation to catch errors early in the process

Enhance user experience by guiding data entry

Potential Use Cases and Benefits

Data collection forms for customer feedback, ensuring key insights are gathered

Registration tools for events, confirming all necessary information is provided

E-commerce platforms requiring user details to minimize incomplete orders

Internal databases needing comprehensive staff information for efficient management

By implementing the Anneal Required Field feature, you address the common problem of incomplete data. It helps you avoid the hassle of chasing down missing information and supports clear communication with users about what is needed. When data integrity matters, you can rely on this feature to enhance your efficiency and accuracy.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What if I have more questions?

Contact Support

What is the process of annealing?

Annealing is a heat treatment process which alters the microstructure of a material to change its mechanical or electrical properties. Typically, in steels, annealing is used to reduce hardness, increase ductility and help eliminate internal stresses.

What is the difference between full annealing and process annealing?

A full annealing provides a relatively soft, ductile material free of internal stresses. Process annealing, sometimes referred to as stress relief, is carried out at temperatures below the lower critical temperature. This treatment is used to improve the ductility and decrease residual stresses in work-hardened steel.

How does annealing affect microstructure?

During an annexal, metallurgical changes occur that returns the metal to its pre-cold-worked state. These changes result in a reduction of the metal's yield and tensile strength and an increase in its ductility, enabling further cold working.

What does annealing due to the crystalline structure?

It involves heating a material above its recrystallization temperature, maintaining a suitable temperature for a suitable amount of time and then cooling. In annealing, atoms migrate in the crystal lattice and the number of dislocations decreases, leading to a change in ductility and hardness.

How does annealing increase ductility?

Annealing to Increase Metal Ductility. These changes result in a reduction of the metal's yield and tensile strength and an increase in its ductility, enabling further cold working. In order for these changes to occur, the metal must be heated above its recrystallization temperature.

What is full annealing process?

Full annealing consists of heating steel to above the upper critical temperature, and slow cooling, usually in the furnace. It is generally only necessary to apply full annealing cycles to the higher alloy or higher carbon steels. This process is only applicable to plain carbon and low alloy steels.

What is difference between annealing tempering and normalizing?

The main difference between annealing and normalizing is that annealing allows the material to cool at a controlled rate in a furnace. Normalizing allows the material to cool by placing it in a room temperature environment and exposing it to the air in that environment.

Why is tempering done after normalizing?

Tempering is usually performed after hardening, to reduce some excess hardness, and is done by heating the metal to some temperature below the critical point for a certain period of time, then allowing it to cool in still air.

What is the difference between annealing hardening and tempering?

The main difference between annealing hardening and tempering is that annealing is done to soften a metal or an alloy and hardening is done to increase the hardness of a metal or alloy whereas tempering is done to reduce the brittleness of quenched metal or alloy.

What is the difference between hardening and tempering?

As the names imply, hardening makes the metal more rigid but more brittle, and tempering (from “temperate", moderate), forgoes some hardness for increased toughness.

What is the main purpose of annealing?

Annealing. In general, the main purpose of annealing heat treatment is to soften the steel, regenerate overheated steel structures or just remove internal tensions. It basically consists of heating to austenitizing temperature (800ºC and 950ºC depending on the type of steel), followed by slow cooling.

What is the tempering process?

Tempering, in metallurgy, process of improving the characteristics of a metal, especially steel, by heating it to a high temperature, though below the melting point, then cooling it, usually in air. The process has the effect of toughening by lessening brittleness and reducing internal stresses.

What is hardening and tempering?

A treatment in which a part is subjected to two complete hardening operations, or first an annealing process followed by a hardening process. Tempering. Tempering is a low temperature heat treatment process normally performed after a hardening process in order to reach a desired hardness/toughness ratio.

What is the annealing process?

Annealing is a heat treatment process which alters the microstructure of a material to change its mechanical or electrical properties. Typically, in steels, annealing is used to reduce hardness, increase ductility and help eliminate internal stresses.

What is the annealing temperature of copper?

Annealing the copper requires a high temperature. Copper melts at 1357Kelvin and annealing generally occurs at greater than half the melting point in degrees K; even higher temperature causes faster annealing (but not past the melting temperature, of course). Typical temperature to use is 400C or 700F.

#1 usability according to G2

Try the PDF solution that respects your time.