Crack Identification Application For Free

Drop document here to upload

Up to 100 MB for PDF and up to 25 MB for DOC, DOCX, RTF, PPT, PPTX, JPEG, PNG, JFIF, XLS, XLSX or TXT

Note: Integration described on this webpage may temporarily not be available.

0

Forms filled

0

Forms signed

0

Forms sent

Discover the simplicity of processing PDFs online

Upload your document in seconds

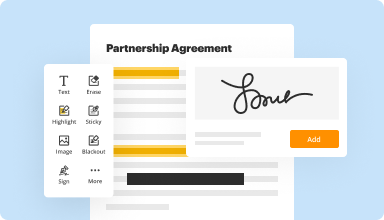

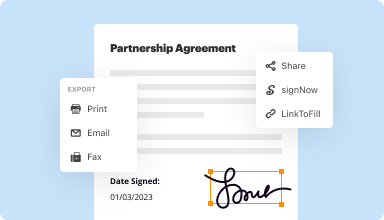

Fill out, edit, or eSign your PDF hassle-free

Download, export, or share your edited file instantly

Top-rated PDF software recognized for its ease of use, powerful features, and impeccable support

Every PDF tool you need to get documents done paper-free

Create & edit PDFs

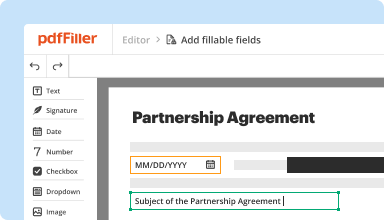

Generate new PDFs from scratch or transform existing documents into reusable templates. Type anywhere on a PDF, rewrite original PDF content, insert images or graphics, redact sensitive details, and highlight important information using an intuitive online editor.

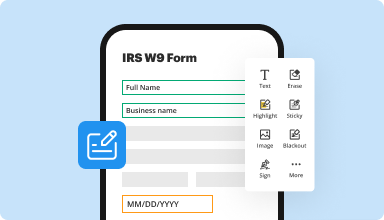

Fill out & sign PDF forms

Say goodbye to error-prone manual hassles. Complete any PDF document electronically – even while on the go. Pre-fill multiple PDFs simultaneously or extract responses from completed forms with ease.

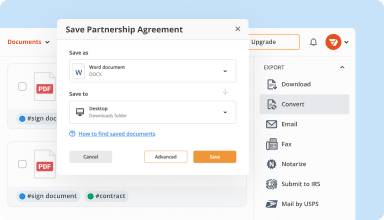

Organize & convert PDFs

Add, remove, or rearrange pages inside your PDFs in seconds. Create new documents by merging or splitting PDFs. Instantly convert edited files to various formats when you download or export them.

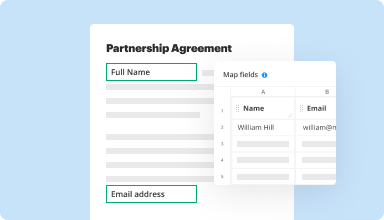

Collect data and approvals

Transform static documents into interactive fillable forms by dragging and dropping various types of fillable fields on your PDFs. Publish these forms on websites or share them via a direct link to capture data, collect signatures, and request payments.

Export documents with ease

Share, email, print, fax, or download edited documents in just a few clicks. Quickly export and import documents from popular cloud storage services like Google Drive, Box, and Dropbox.

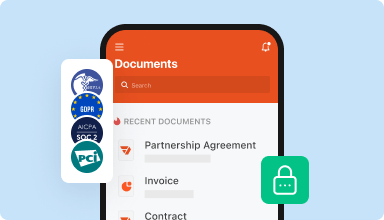

Store documents safely

Store an unlimited number of documents and templates securely in the cloud and access them from any location or device. Add an extra level of protection to documents by locking them with a password, placing them in encrypted folders, or requesting user authentication.

Customer trust by the numbers

64M+

users worldwide

4.6/5

average user rating

4M

PDFs edited per month

9 min

average to create and edit a PDF

Join 64+ million people using paperless workflows to drive productivity and cut costs

Why choose our PDF solution?

Cloud-native PDF editor

Access powerful PDF tools, as well as your documents and templates, from anywhere. No installation needed.

Top-rated for ease of use

Create, edit, and fill out PDF documents faster with an intuitive UI that only takes minutes to master.

Industry-leading customer service

Enjoy peace of mind with an award-winning customer support team always within reach.

What our customers say about pdfFiller

See for yourself by reading reviews on the most popular resources:

What do you like best?

I really like the fact that you can create your own templates and save them for future use. I also like being able to send a text to another party and have them sign electronically.

What do you dislike?

The only real complaint I have is that I keep getting signed out.

Recommendations to others considering the product:

I highly recommend PDF Filler to anyone that needs the ability to edit, create, and manage PDFs. It is easy to use and has a great price point.

What problems are you solving with the product? What benefits have you realized?

PDF Filler makes it incredibly easy to redact documents.

I really like the fact that you can create your own templates and save them for future use. I also like being able to send a text to another party and have them sign electronically.

What do you dislike?

The only real complaint I have is that I keep getting signed out.

Recommendations to others considering the product:

I highly recommend PDF Filler to anyone that needs the ability to edit, create, and manage PDFs. It is easy to use and has a great price point.

What problems are you solving with the product? What benefits have you realized?

PDF Filler makes it incredibly easy to redact documents.

2019-01-28

Blogger - PDF Filler

Online use without having to download anything onto your computer. If you are a blogger you have too much on your desktop already!

Easy to use. No need to have other software to fill-in your PDFs (contracts, flyers, etc.). This can be used online on any computer. You can even have docs e-signed. There's also a free trial.

I do not have anything bad to say about it. It was easy to use. I will continue to use and refer people to it.

2020-01-07

The products are awesome and have been essential to the success of my business!

The forms are very easy to access and to use. The ability to have access to such a variety of forms especially IRS forms. The freedom of use to so many forms and the ability to upload your own created forms far exceeds so many other products that have so many limitations on the use of their products.

My only complaint is that sometimes it is a little difficult to find certain forms that you are looking for but it is usually remedied rather quickly.

2017-11-14

Easy to use and very helpful in my business

I use this PDF Filler multiple times daily and it is so easy to use and makes my life so much easier when doing many things.

2024-03-11

This was my first test

This was my first test, it seemed to go very well, I've tried a few of these programs and to be honest, this one works the best. I will have to explore it a little further to see if it does what I need todo. Actually so far it's the best I've tried. Actually I think that it offers more than I really need, but if it fits and completes everything I plan on doing that to me would be 100%.

2020-11-11

I've been using Pdffiller for several…

I've been using Pdffiller for several years now and couldn't have asked for anything more from this company. I recently upgraded my account to premium for even more services. I'll be around with this company for many more years!

2020-11-07

I love how customizable the website makes any file. Its exactly what I was looking for in order to fill out various forms due to the pandemic. Ways to communicate are different now and this website is definitely with the times.

2020-10-23

I've been using different apps for…

I've been using different apps for years that take me about 15-30 minutes to change one document but with PDFfiller it took me less than two minutes! so worth the yearly fee.

2020-10-03

So far so good.

I like the friendly interface and the different options of sending processed files.

I would like to request developers to incoporate "rotating page" for some documents that may be uploaded upside down

2020-08-19

Crack Identification Application

The Crack Identification Application is designed to help you detect and manage cracks in various materials effectively. Whether you are a homeowner, contractor, or inspector, this application will assist you in identifying issues early, ensuring safety and longevity of your structures.

Key Features

User-friendly interface for easy navigation

Real-time crack detection using advanced imaging technology

Historical tracking of crack development over time

Instant alerts for significant changes in crack size

Customized reporting for detailed assessments

Potential Use Cases and Benefits

Inspect residential properties for foundation issues

Monitor infrastructure such as bridges and roads

Provide contractors with accurate assessments before repairs

Educate homeowners on maintenance through historical data

Improve safety measures by identifying structural risks early

This application addresses your need for an efficient solution to crack management. By using advanced detection technology, it allows you to respond promptly to issues before they escalate. You can save time and resources while maintaining the integrity of your structures, leading to fewer repairs and improved safety for everyone.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What if I have more questions?

Contact Support

What is crack detection?

Crack detection is the process of detecting the crack in the structures using any of the processing techniques. The crack detection can be made in two ways. They are Destructive Testing and Non-Destructive testing.

What is crack testing?

The crack testing refers to various methods for the detection and assessment of cracks in materials and safety or consequential costs relevant components, e.g. pressure vessels, pipes and components of the automotive or aerospace industry.

How can you tell if metal is cracked?

methods of detecting cracks in metals. It simply involves inducing electric currents inside the object being tested and then observing the electromagnetic response. When this test is set up properly, a defect in the metal or other solid object being tested will create a response that can be measured immediately.

What is meant by NDT test?

Methods and Definition. Contact Us. Non-destructive testing (NDT) is a testing and analysis technique used by industry to evaluate the properties of a material, component, structure or system for characteristic differences or welding defects and discontinuities without causing damage to the original part.

How do you test cracks for welding?

Liquid penetrant testing is done with either “visible dye” or fluorescent dye. With fluorescent penetrant inspection, a highly fluorescent liquid is applied to the surface of the inspection area(s). A developer is then applied to draw the penetrant to the surface, and then a black light is used to inspect the weld.

How can you tell if a weld is cracked?

Liquid penetrant testing is done with either “visible dye” or fluorescent dye. With fluorescent penetrant inspection, a highly fluorescent liquid is applied to the surface of the inspection area(s). A developer is then applied to draw the penetrant to the surface, and then a black light is used to inspect the weld.

What causes welds to crack?

Cracking can be caused by many problems from rapid cooling to contamination. But in almost all cases, the reason cracking occurs is that the internal stresses exceed either your weld, your base metal or both. After you weld, both your base metal and your weld begin shirking as they cool.

How do welders prevent crater cracks?

The easiest way to prevent crater cracks in aluminum MIG welds is to “back step” at the end of the weld. Instead of releasing the trigger at the end of the weld, reverse the travel direction back into the already welded material.

#1 usability according to G2

Try the PDF solution that respects your time.