Crack Initials Attestation For Free

Drop document here to upload

Up to 100 MB for PDF and up to 25 MB for DOC, DOCX, RTF, PPT, PPTX, JPEG, PNG, JFIF, XLS, XLSX or TXT

Note: Integration described on this webpage may temporarily not be available.

0

Forms filled

0

Forms signed

0

Forms sent

Discover the simplicity of processing PDFs online

Upload your document in seconds

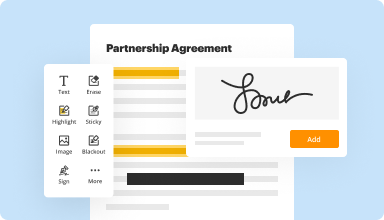

Fill out, edit, or eSign your PDF hassle-free

Download, export, or share your edited file instantly

Top-rated PDF software recognized for its ease of use, powerful features, and impeccable support

Every PDF tool you need to get documents done paper-free

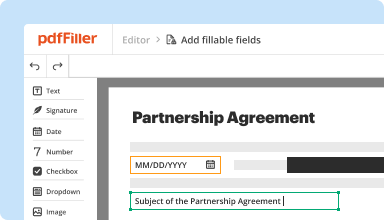

Create & edit PDFs

Generate new PDFs from scratch or transform existing documents into reusable templates. Type anywhere on a PDF, rewrite original PDF content, insert images or graphics, redact sensitive details, and highlight important information using an intuitive online editor.

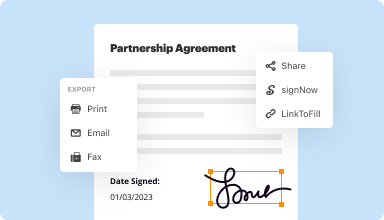

Fill out & sign PDF forms

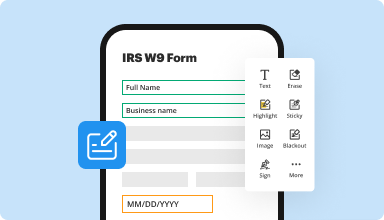

Say goodbye to error-prone manual hassles. Complete any PDF document electronically – even while on the go. Pre-fill multiple PDFs simultaneously or extract responses from completed forms with ease.

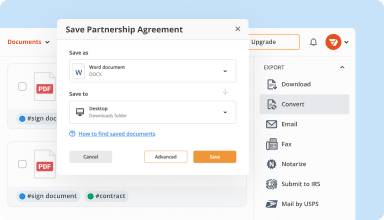

Organize & convert PDFs

Add, remove, or rearrange pages inside your PDFs in seconds. Create new documents by merging or splitting PDFs. Instantly convert edited files to various formats when you download or export them.

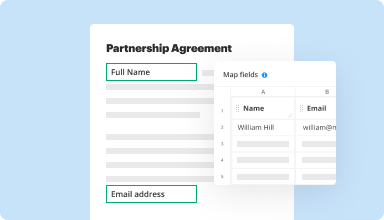

Collect data and approvals

Transform static documents into interactive fillable forms by dragging and dropping various types of fillable fields on your PDFs. Publish these forms on websites or share them via a direct link to capture data, collect signatures, and request payments.

Export documents with ease

Share, email, print, fax, or download edited documents in just a few clicks. Quickly export and import documents from popular cloud storage services like Google Drive, Box, and Dropbox.

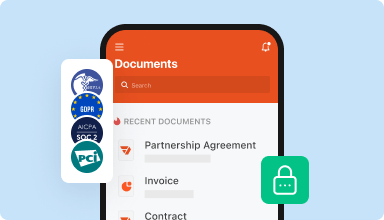

Store documents safely

Store an unlimited number of documents and templates securely in the cloud and access them from any location or device. Add an extra level of protection to documents by locking them with a password, placing them in encrypted folders, or requesting user authentication.

Customer trust by the numbers

64M+

users worldwide

4.6/5

average user rating

4M

PDFs edited per month

9 min

average to create and edit a PDF

Join 64+ million people using paperless workflows to drive productivity and cut costs

Why choose our PDF solution?

Cloud-native PDF editor

Access powerful PDF tools, as well as your documents and templates, from anywhere. No installation needed.

Top-rated for ease of use

Create, edit, and fill out PDF documents faster with an intuitive UI that only takes minutes to master.

Industry-leading customer service

Enjoy peace of mind with an award-winning customer support team always within reach.

What our customers say about pdfFiller

See for yourself by reading reviews on the most popular resources:

Very limited use so far. Can't figure out how to select another form, either of the same type just completed or a different form without going back to the start page manually. Otherwise so far so good.

2017-01-30

Really good experience! I used it for UK Law Society forms relating to the sale of my property. The forms are excellently produced and easy to complete and save. The functionality is REALLY good!

2018-02-20

It's very good app. The cost for what it offers is alot better then having a Adobe subscription. You can fax and a whole bunch of things. It just made my life easy.

2019-06-22

It's the best experience on pdf editors, the only thing is that i passed 10 minutes just to find how to change the color of the text, i suggest to modify the icon of the text color for better user experience and as a back-end developer I thank you for the work you are doing, work for your project, believe on it and you will have more success. I hope you share my comment with all your team, this will motivate them to do more effort for pdfFiller. have a nice day, stay positive and good luck.

2022-03-31

this was very helpful making legal forms, a lot of options to navigate. I would definitely recommend this product to others.

The price is more than I would like to pay, so I probably will use temporarily but I'm sure I will return.

2022-01-12

Excellent Customer Service

Asked for a refund and got an immediate response and an immediate credit - no questions, no bull. If I needed this service - I'd buy it here!

2021-12-16

pdfFiller is an very valuable software…

pdfFiller is an very valuable software for work at home or outside. They have an excellent customer service which helped me instantly. You can easily edit, combine files, put your own online signature and save a lot of time by using this software. Very easy to handle, sort, upload, share files etc.! Mirko M.

2021-08-26

had to find something quick to fill out a form online and came across pdfFiller and tried it out. I was more than satisfied. I am trying the 30 day trial out and will comment when the time is up.

2021-04-26

Elisa stepped right into action and helped me with my accounting issue. It is so nice to be able to have an account services individual help a customer with ease. This is a very rare occasion especially during this pandemic. Thank you Elisa!!!!!

2020-08-14

Crack Initials Attestation Feature

The Crack Initials Attestation feature helps you confirm and validate initials used in documents. This tool simplifies the process of attesting initials, ensuring accuracy and trust in your important paperwork. Its user-friendly interface guides you through the steps, making it accessible for all.

Key Features

Easy verification of initials in documents

User-friendly dashboard for quick access

Secure log of all attested initials

Support for multiple document types

Customizable templates for varied needs

Potential Use Cases and Benefits

Streamline the document review process in legal firms

Enhance authenticity in business agreements

Simplify initial verification in educational certificates

Improve workflow efficiency in administrative tasks

Build trust through transparent attestation records

By using the Crack Initials Attestation feature, you can resolve issues related to verifying document authenticity. It saves you time and reduces stress associated with paperwork. Now, you can ensure smooth operations and maintain credibility in your professional dealings.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What if I have more questions?

Contact Support

What is crack tip plasticity?

If plastic deformation occurs, then the elastic stresses are limited by yielding since stress singularity cannot occur, but stress relaxation takes place within the plastic zone. This plastic deformation occurs in a small region, and it is called the crack-tip plastic zone.

What is crack tip singularity?

Controlling the singularity at the crack tip. If the geometry of the crack region defines a sharp crack, the strain field becomes singular at the crack tip, as described in Constructing a fracture mechanics mesh for small-strain analysis with the conventional finite element method.

What is crack theory?

The theory predicts that a crack will propagate in order to lower the total energy of the system, by dissipating the elastic strain energy due to loading into the creation of a new surface.

What is singularity in fracture mechanics?

It is known from Chapter 3 that linear elastic fracture mechanics (LEFT) predicts an inverse square-root singularity at a crack tip. The stress singularity implies that the elastic stress will exceed the yield stress when approaching the crack tip, and consequently, a plastic zone develops in the crack tip region.

Which mode of crack displacement is most commonly encountered?

Although the fracture of a material may involve either one or a combination of the three crack displacement modes, mode I is the most commonly encountered, and thus, the fracture toughness and fracture energy for mode I are cited for most situations.

Why does a plastic zone form around a crack tip in a ductile metal under tension?

In ductile materials (and even in materials that appear to be brittle), a plastic zone develops at the tip of the crack. As the applied load increases, the plastic zone increases in size until the crack grows and the elastically strained material behind the crack tip unloads.

Why does a plastic zone form at the tip of a crack when the cracked body is loaded in tension?

As a cracked body is loaded, a plastic zone will grow at the crack tip as described in §11.3. At a sufficiently high load amplitude the material near the crack tip will yield in compression.

How does the stress concentration around a crack tip depend on crack geometry and size?

Note that the stress concentration factor is a function of the geometry of a crack or notch, and not of its size. As the radius of curvature approaches zero, like the tip of a sharp crack, the maximum stress approaches infinity and therefore stress concentration factors cannot be used for a crack.

#1 usability according to G2

Try the PDF solution that respects your time.