90 Day Equipment Inspection Form Templates

What are 90 Day Equipment Inspection Form Templates?

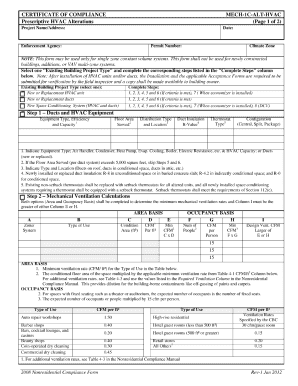

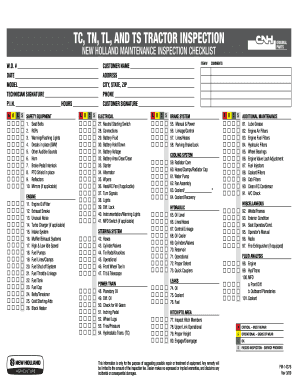

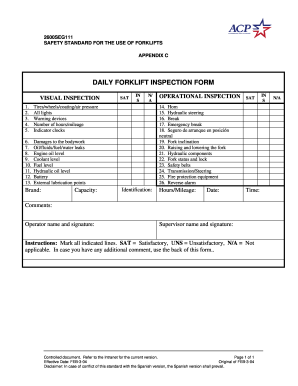

90 Day Equipment Inspection Form Templates are documents used to track and record the inspection details of various equipment or machinery over a 90-day period. These templates help in ensuring proper maintenance and compliance with safety regulations.

What are the types of 90 Day Equipment Inspection Form Templates?

There are several types of 90 Day Equipment Inspection Form Templates available, including but not limited to:

Construction equipment inspection forms

Vehicle inspection forms

Industrial machinery inspection forms

Medical equipment inspection forms

How to complete 90 Day Equipment Inspection Form Templates

To effectively complete 90 Day Equipment Inspection Form Templates, follow these simple steps:

01

Fill in the details of the equipment being inspected

02

Record the date of inspection and the inspector's information

03

Check off the items or components being inspected

04

Note down any issues or concerns found during inspection

05

Sign and date the form to authenticate the inspection

pdfFiller empowers users to create, edit, and share documents online. Offering unlimited fillable templates and powerful editing tools, pdfFiller is the only PDF editor users need to get their documents done.

Video Tutorial How to Fill Out 90 Day Equipment Inspection Form Templates

Thousands of positive reviews can’t be wrong

Read more or give pdfFiller a try to experience the benefits for yourself

Questions & answers

How do I make an inspection checklist?

Keep checklists short and focused As long as you have checklists established around problems that come up commonly, you do not need to have an item listed for every detail of a task. Inspection checklists should have only 10-20 check points to heighten the inspector's awareness of critical items.

What is inspection forms?

An inspection checklist (also referred to as an inspection sheet) is an essential tool for inspectors and professionals across multiple industries. Inspection checklists help assess the compliance of a process, procedure, equipment, or facility with industry, governmental, or internal standards.

How do you create a safety checklist?

How To Build A Safety Inspection Checklist: 5 Steps Determine your safety inspection checklist needs. Look to other examples. Work with SMEs to build your workplace safety inspection checklist. Build safety checklists that are automated or site-specific. Incorporate ongoing audits to ensure compliance.

What details should be in a field inspection report?

Job Site Location: Indicate the exact location that is being inspected. Specific Equipment Numbers: Specify which equipment is getting inspected. Condition of Equipment: Observe and report on equipment condition. Any Recommended Actions: Recommend maintenance or repair measures.

What are the 5 basic kinds of inspection methods?

Different types of QC inspections Pre-Production Inspections (PPI) During Production Inspection (DPI) Pre-Shipment Inspection (PSI) Piece by Piece Inspection (or Sorting Inspection) Loading and unloading supervision.

What are two key components to a well written statement in a written inspection report?

There are two KEY components to a statement: 1. Report type of DEFICIENCY or DEFECT. 2. Report the LOCATION of the deficiency or defect.