Manufacturing Inspection Report Template

What is manufacturing inspection report template?

A manufacturing inspection report template is a document that provides a standardized format for recording and reporting the results of inspections conducted in the manufacturing industry. It includes sections for documenting the inspection date, location, inspector's name, and details of the items or processes being inspected. The template serves as a valuable tool for ensuring quality control and identifying areas for improvement in the manufacturing process.

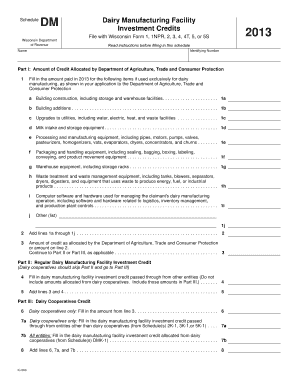

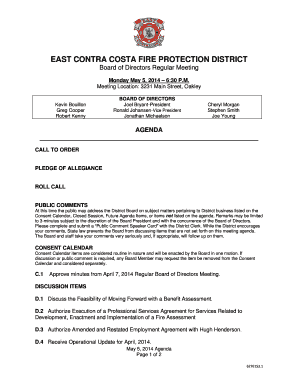

What are the types of manufacturing inspection report template?

There are several types of manufacturing inspection report templates available, depending on the specific needs of the industry. Some common types include: 1. Product Inspection Report Template: This template focuses on inspecting finished products to ensure they meet quality standards. 2. Process Inspection Report Template: This template is used to document inspections of manufacturing processes, such as equipment calibration, raw material testing, and production line checks. 3. Supplier Inspection Report Template: This template is used when conducting inspections of suppliers to evaluate their compliance with quality standards and specifications. 4. Facility Inspection Report Template: This template is designed for assessing the overall condition and compliance of manufacturing facilities with safety and regulatory requirements.

How to complete manufacturing inspection report template

Completing a manufacturing inspection report template is a straightforward process that involves the following steps: 1. Start by providing the necessary information, such as the inspection date, location, and the name of the inspector. 2. Describe the items or processes being inspected in detail, including any specifications or criteria that need to be met. 3. Use checklists, tick boxes, or other methods to indicate the findings of the inspection. This can include information on whether the items or processes passed or failed the inspection, as well as any observations or recommendations for improvement. 4. Include any supporting documentation, such as photographs or test results, that may be relevant to the inspection. 5. Review the completed report for accuracy and make any necessary revisions. 6. Share the report with relevant stakeholders, such as managers, production teams, or quality control personnel.

pdfFiller empowers users to create, edit, and share documents online, including manufacturing inspection report templates. With unlimited fillable templates and powerful editing tools, pdfFiller is the all-in-one PDF editor that users need to efficiently complete their documents.