What is Inspection Checklist?

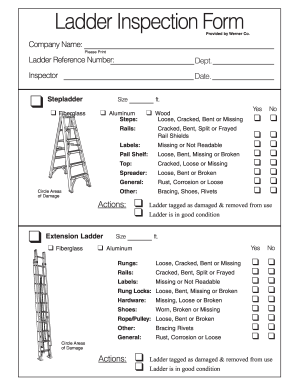

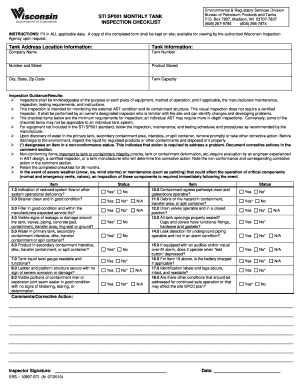

An Inspection Checklist is a detailed list of items or tasks that need to be reviewed, examined, or evaluated during an inspection process. It serves as a guide or reference to ensure that all necessary aspects are inspected and assessed accurately. Whether it's for quality control, safety inspection, property evaluation, or any other purpose, an Inspection Checklist helps to streamline the inspection process and ensure that nothing important is overlooked.

What are the types of Inspection Checklist?

There are various types of Inspection Checklists, each tailored to a specific area or industry. Some common types include:

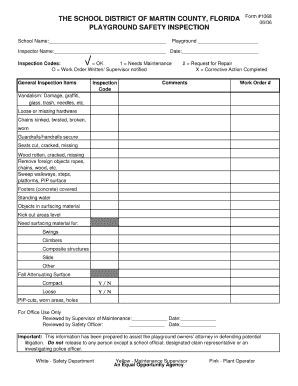

Safety Inspection Checklist: Focuses on identifying potential hazards, ensuring compliance with safety regulations, and promoting a safe environment.

Quality Control Inspection Checklist: Aims to check and maintain the quality of products, materials, or services.

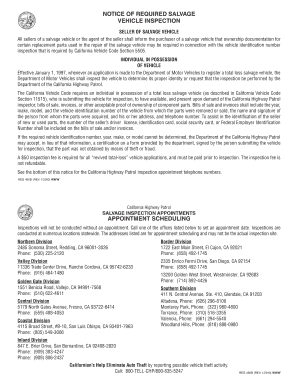

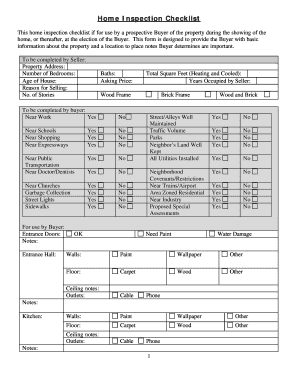

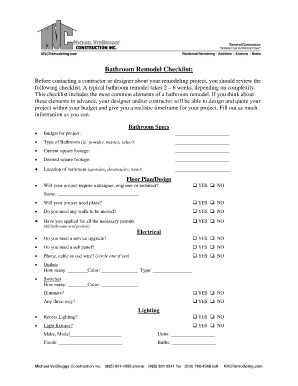

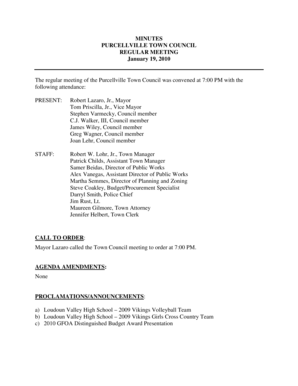

Property Inspection Checklist: Used for evaluating the condition and functionality of a property, including its structure, systems, and amenities.

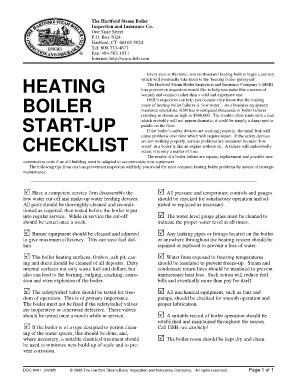

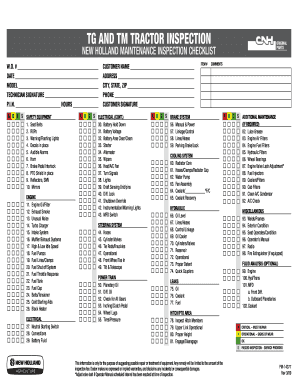

Maintenance Inspection Checklist: Helps in monitoring and evaluating the upkeep and maintenance of equipment, facilities, or vehicles.

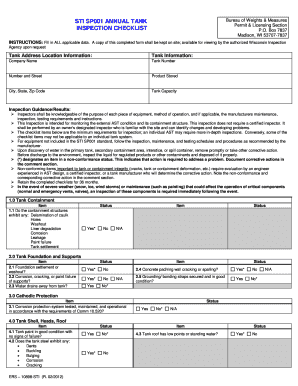

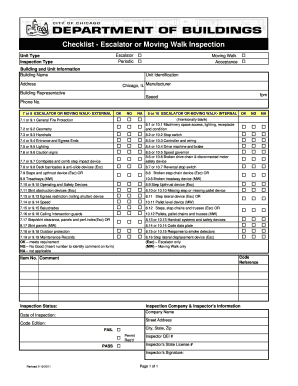

Compliance Inspection Checklist: Ensures adherence to specific standards, guidelines, or regulatory requirements.

How to complete Inspection Checklist

Completing an Inspection Checklist can be a systematic and efficient process by following these steps:

01

Review the Checklist: Familiarize yourself with the Checklist and understand its requirements and objectives.

02

Collect necessary tools and resources: Gather all the equipment, reference materials, or documents needed to perform the inspection thoroughly.

03

Start at the top: Begin the inspection process from the first item on the Checklist and proceed systematically.

04

Document findings: Record your observations, findings, or notes accurately for each item on the Checklist.

05

Take photos if necessary: Use a camera or other appropriate means to capture visual evidence or support your findings.

06

Address any issues: If any issues or deficiencies are identified during the inspection, take appropriate action to resolve them.

07

Review and verify: Double-check your work, ensuring that all items on the Checklist have been adequately addressed and inspected.

08

Submit or share the Checklist: Once the inspection is complete, submit or share the Checklist with the relevant parties as needed.

pdfFiller empowers users to create, edit, and share documents online. Offering unlimited fillable templates and powerful editing tools, pdfFiller is the only PDF editor users need to get their documents done.