Get the free WELDING INSPECTION REPORT - dot ca

Show details

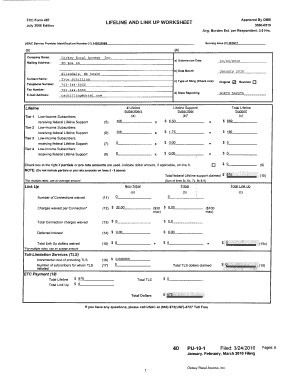

STATE OF CALIFORNIABUSINESS, TRANSPORTATION AND HOUSING AGENCY Arnold Schwarzenegger, Governor DEPARTMENT OF TRANSPORTATION DIVISION OF ENGINEERING SERVICES Office of Structural Materials Quality

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign welding inspection report

Edit your welding inspection report form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your welding inspection report form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit welding inspection report online

Follow the steps down below to take advantage of the professional PDF editor:

1

Register the account. Begin by clicking Start Free Trial and create a profile if you are a new user.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit welding inspection report. Rearrange and rotate pages, insert new and alter existing texts, add new objects, and take advantage of other helpful tools. Click Done to apply changes and return to your Dashboard. Go to the Documents tab to access merging, splitting, locking, or unlocking functions.

4

Get your file. Select your file from the documents list and pick your export method. You may save it as a PDF, email it, or upload it to the cloud.

pdfFiller makes working with documents easier than you could ever imagine. Register for an account and see for yourself!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out welding inspection report

How to fill out a welding inspection report:

01

Start by entering the necessary information at the top of the report, such as the date, project name, welding inspector's name, and any specific requirements or codes applicable to the inspection.

02

Identify the location of the weld that requires inspection. This could be specified by the project name, part number, drawing number, or any other relevant identification.

03

Evaluate the weld quality by examining factors such as welding procedure, joint type, weld size, weld shape, and visual appearance. Record these observations accurately and thoroughly in the inspection report.

04

Measure the weld dimensions, if applicable, using appropriate tools such as calipers, gauges, or rulers. Document these measurements in the report to ensure compliance with the specified requirements.

05

Check the weld for any defects or non-conformances, such as cracks, porosity, lack of fusion, or excessive weld spatter. Note these issues in the report and include any recommendations for corrective actions if needed.

06

Verify the welding materials used, including the type of filler metal, shielding gas, flux, or any other consumables. Confirm that they meet the specified requirements and include this information in the report.

07

Assess the welding parameters utilized during the fabrication process, such as voltage, amperage, travel speed, and preheat temperature. Ensure they comply with the applicable standards or specifications and document them in the inspection report.

08

If any destructive or non-destructive testing was performed on the weld, record the results accurately. This may include radiographic (X-ray) testing, ultrasonic testing, liquid penetrant testing, or any other relevant methods used to examine the weld integrity.

09

Sign and date the completed welding inspection report to validate its accuracy and authenticity. Additionally, provide any additional notes or comments that may be important for the stakeholders involved in the project.

Who needs a welding inspection report?

01

Engineers and designers: They need the inspection report to ensure that the welded components meet the required quality standards and specifications.

02

Welding inspectors: The report is crucial to documenting their findings, observations, and recommendations for any necessary corrective actions. It serves as an official record of their inspection and helps ensure accountability.

03

Fabricators and welders: The report provides vital feedback on the quality of their work, allowing them to identify areas of improvement and make any necessary adjustments to the welding processes.

04

Project managers and contractors: They rely on the inspection report to ensure that the completed welds meet industry standards and regulatory requirements. The report helps them track the progress of the welding activities and make informed decisions regarding project timelines and budgets.

05

Regulatory bodies and quality control authorities: The inspection report is a key document in compliance with industry standards and regulations. It helps these entities ensure that the welding processes and products meet the necessary safety and quality criteria.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I sign the welding inspection report electronically in Chrome?

Yes. You can use pdfFiller to sign documents and use all of the features of the PDF editor in one place if you add this solution to Chrome. In order to use the extension, you can draw or write an electronic signature. You can also upload a picture of your handwritten signature. There is no need to worry about how long it takes to sign your welding inspection report.

Can I edit welding inspection report on an iOS device?

Use the pdfFiller app for iOS to make, edit, and share welding inspection report from your phone. Apple's store will have it up and running in no time. It's possible to get a free trial and choose a subscription plan that fits your needs.

How do I complete welding inspection report on an iOS device?

Make sure you get and install the pdfFiller iOS app. Next, open the app and log in or set up an account to use all of the solution's editing tools. If you want to open your welding inspection report, you can upload it from your device or cloud storage, or you can type the document's URL into the box on the right. After you fill in all of the required fields in the document and eSign it, if that is required, you can save or share it with other people.

What is welding inspection report?

A welding inspection report is a document that records the results of inspections carried out on welds to ensure they meet the required standards.

Who is required to file welding inspection report?

Welding inspectors or certified welding inspectors are required to file welding inspection reports.

How to fill out welding inspection report?

To fill out a welding inspection report, the inspector must document all relevant information about the welds inspected, including the location, type of weld, defects found, and corrective actions taken.

What is the purpose of welding inspection report?

The purpose of a welding inspection report is to ensure that welds meet the required standards for safety and functionality.

What information must be reported on welding inspection report?

Information such as the location of the weld, type of weld, defects found, corrective actions taken, and inspector's signature must be reported on a welding inspection report.

Fill out your welding inspection report online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Welding Inspection Report is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.