Get the free JOINT WELDING

Show details

JOINT WELDING

PROCEDURE SPECIFICATION

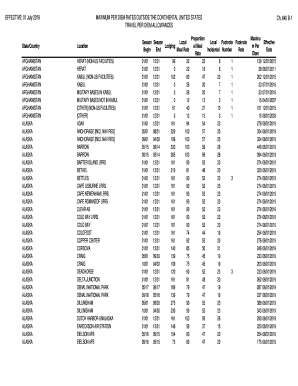

All information must be completed08/17Material specification

Welding process

Manual or machine

Position of welding

Filler metal specification

Filler metal manufacturer

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign joint welding

Edit your joint welding form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your joint welding form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit joint welding online

Use the instructions below to start using our professional PDF editor:

1

Register the account. Begin by clicking Start Free Trial and create a profile if you are a new user.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit joint welding. Rearrange and rotate pages, add new and changed texts, add new objects, and use other useful tools. When you're done, click Done. You can use the Documents tab to merge, split, lock, or unlock your files.

4

Save your file. Select it from your list of records. Then, move your cursor to the right toolbar and choose one of the exporting options. You can save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud, among other things.

It's easier to work with documents with pdfFiller than you could have believed. You may try it out for yourself by signing up for an account.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out joint welding

How to fill out joint welding?

01

Prepare the materials needed for joint welding, such as the metal pieces to be welded, a welding machine, welding electrodes or filler wire, welding gloves, and safety goggles.

02

Ensure that the metal pieces are clean and free from any rust, dirt, or oil. Use a wire brush or sandpaper to remove any contaminants.

03

Position the metal pieces in the desired joint configuration, ensuring that the fit-up is tight and accurate.

04

Set up the welding machine according to the manufacturer's instructions, ensuring that the appropriate settings for current, voltage, and wire feed speed are selected.

05

Put on the welding gloves and safety goggles to protect yourself from sparks and UV radiation.

06

Start the welding process by striking an arc between the welding electrode or filler wire and the metal pieces to be joined. This can be done by gently tapping the electrode against the metal or by using a foot pedal or trigger switch, depending on the type of welding machine.

07

Move the welding electrode or filler wire along the joint in a controlled manner, maintaining a consistent arc length and travel speed. This will ensure proper fusion and penetration of the weld.

08

Use weaving or oscillating motions if necessary, especially for thicker metals or to create stronger welds.

09

Continue welding until the entire joint is filled with the desired amount of weld metal.

10

Allow the welded joint to cool slowly, ensuring that it is not disturbed or exposed to rapid cooling. This will help prevent stress cracking or distortion in the weld.

11

Inspect the completed weld for any defects, such as porosity, cracks, or incomplete fusion. If necessary, clean and rework the weld to ensure its strength and integrity.

Who needs joint welding?

01

Manufacturing industries: Joint welding is commonly used in manufacturing industries such as automotive, aerospace, construction, and shipbuilding to join metal components and structures.

02

Metal fabrication companies: Joint welding is an essential process for metal fabrication companies that specialize in custom-made products, structural steelwork, or repairs.

03

Maintenance and repair services: Joint welding is often required in maintenance and repair services to fix or strengthen existing metal structures, machinery, or equipment.

04

Construction sector: Joint welding is extensively used in the construction sector for erecting steel frameworks, bridges, pipelines, and other infrastructure projects.

05

Artistic and sculptural projects: Joint welding is employed by artists and sculptors to create intricate metal artworks and sculptures.

06

DIY enthusiasts and hobbyists: Joint welding can also be learned and utilized by DIY enthusiasts and hobbyists who enjoy working with metal and want to create their own projects or repairs.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is joint welding?

Joint welding is a process of joining two or more metal pieces together using heat or pressure to create a strong bond.

Who is required to file joint welding?

Manufacturers, fabricators, and contractors who perform welding on structural components are required to file joint welding.

How to fill out joint welding?

To fill out joint welding, you need to provide details about the materials being welded, welding process used, welder qualifications, and inspection records.

What is the purpose of joint welding?

The purpose of joint welding is to create a secure and durable connection between metal pieces for structural integrity and safety.

What information must be reported on joint welding?

Information such as welding procedure specifications, welder qualifications, pre-welding and post-welding inspections, and any repairs or modifications made during the welding process must be reported on joint welding.

How do I complete joint welding online?

pdfFiller has made filling out and eSigning joint welding easy. The solution is equipped with a set of features that enable you to edit and rearrange PDF content, add fillable fields, and eSign the document. Start a free trial to explore all the capabilities of pdfFiller, the ultimate document editing solution.

How do I make edits in joint welding without leaving Chrome?

joint welding can be edited, filled out, and signed with the pdfFiller Google Chrome Extension. You can open the editor right from a Google search page with just one click. Fillable documents can be done on any web-connected device without leaving Chrome.

How can I edit joint welding on a smartphone?

The pdfFiller apps for iOS and Android smartphones are available in the Apple Store and Google Play Store. You may also get the program at https://edit-pdf-ios-android.pdffiller.com/. Open the web app, sign in, and start editing joint welding.

Fill out your joint welding online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Joint Welding is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.