Get the free Process Costing Report - csus

Show details

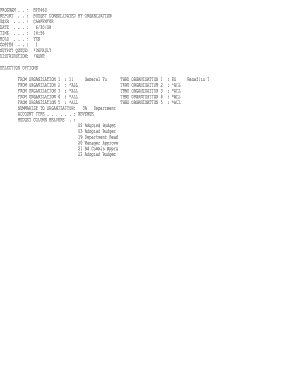

This document provides a detailed calculation of equivalent units and costs for manufacturing processes using the weighted-average method, along with a cost reconciliation report.

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign process costing report

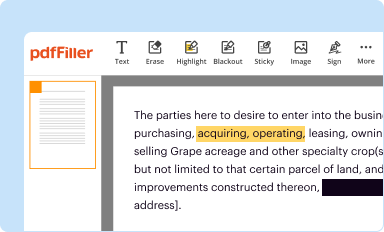

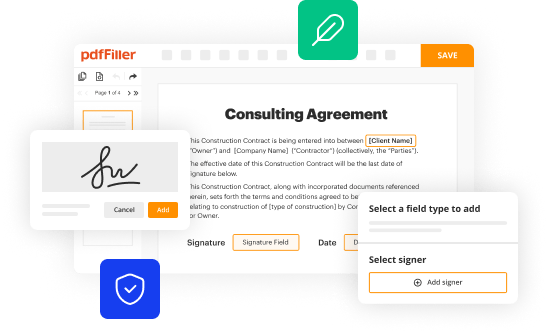

Edit your process costing report form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

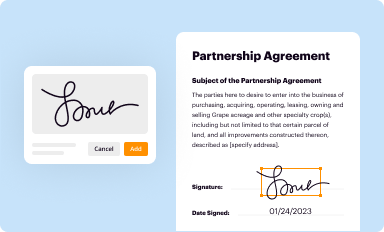

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

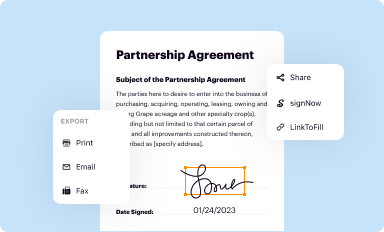

Share your form instantly

Email, fax, or share your process costing report form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit process costing report online

Follow the steps below to use a professional PDF editor:

1

Set up an account. If you are a new user, click Start Free Trial and establish a profile.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit process costing report. Add and change text, add new objects, move pages, add watermarks and page numbers, and more. Then click Done when you're done editing and go to the Documents tab to merge or split the file. If you want to lock or unlock the file, click the lock or unlock button.

4

Save your file. Select it from your list of records. Then, move your cursor to the right toolbar and choose one of the exporting options. You can save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud, among other things.

pdfFiller makes dealing with documents a breeze. Create an account to find out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out process costing report

How to fill out Process Costing Report

01

Identify the period for which the report is being generated.

02

Gather all relevant data on production costs, including materials, labor, and overhead.

03

List each process or department involved in production and their respective costs.

04

Calculate the cost per unit for each process by dividing total costs by the number of units produced.

05

Document any beginning and ending work in process inventories for each department.

06

Report total costs for each process and summarize them in the report format.

Who needs Process Costing Report?

01

Manufacturing companies involved in continuous production processes.

02

Accountants and financial analysts for cost analysis and budgeting.

03

Management for decision-making and performance evaluation.

04

Investors and stakeholders interested in financial reports and profitability.

Fill

form

: Try Risk Free

People Also Ask about

What are the five steps to follow when computing costs using a process costing system?

Businesses using the process costing system typically take the following five steps to arrive at a per-unit cost: Analyze inventory. Analyze the flow of products during the period. Calculate equivalent units. Tally total applicable costs. Calculate per-unit cost. Allocate total costs to finished and unfinished goods.

What is process costing pdf?

Process costing is used to ascertain the cost of a product at each stage of production. The output of one process becomes the input of the next process. This method of costing is adopted by industries engaged in manufacturing.

What are the five steps in process costing?

The five steps in process costing are to analyze inventory, convert incomplete units to completed units equivalent, determine total expenses, calculate cost per unit of output, and allocate costs to completed and incomplete units.

What is process costing with example?

Process costing is an important product costing method for manufacturing companies that mass produce a large volume of similar products or units of output. Process costing is widely used in industries such as oil refining, food production, chemical processing, textiles, glass, cement and paint manufacture.

What are the 5 steps in process costing?

The steps of process costing are; Step 1: summarize the flow of physical units. Step 2: Compute output in terms of equivalent units. Step 3: Calculate costs per equivalent unit costs. Step 4: Summarize total costs to account for. Step 5: Assign costs for finished products and work in process products.

How to prepare a costing report?

How can you prepare a cost of production report? Step 1: Gather the data. Step 2: Calculate the equivalent units. Be the first to add your personal experience. Step 3: Calculate the cost per equivalent unit. Step 4: Allocate the costs to the units. Be the first to add your personal experience. Here's what else to consider.

Which of the following is the first step of the 5 step process costing procedure?

The steps of process costing are; Step 1: summarize the flow of physical units. Step 2: Compute output in terms of equivalent units. Step 3: Calculate costs per equivalent unit costs.

What are the five features of process costing?

Features Each plant is divided into several processes/centers. Direct & indirect costs are assigned and accumulated to each process in the factory. The output of one process may become input for another process. The finished products are identical & cannot be easily distinguished unless batch coding is done.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is Process Costing Report?

A Process Costing Report is a financial document used to track and allocate costs associated with production processes in industries where products are produced in a continuous flow.

Who is required to file Process Costing Report?

Businesses involved in manufacturing or production that utilize process costing methods are required to file a Process Costing Report.

How to fill out Process Costing Report?

To fill out a Process Costing Report, gather relevant data such as production costs, the number of units produced, and any overhead costs. Allocate costs to each process and summarize the total costs associated with the production for the reporting period.

What is the purpose of Process Costing Report?

The purpose of a Process Costing Report is to provide detailed insights into production costs and efficiencies, allowing businesses to analyze their cost structure and make informed budgeting and pricing decisions.

What information must be reported on Process Costing Report?

A Process Costing Report must report information such as total production costs, cost per unit, allocation of direct materials, direct labor, and overhead costs, as well as the number of units produced during the accounting period.

Fill out your process costing report online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Process Costing Report is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.