Get the free A Guide to Best Practices for the Food-Processing Industry

Show details

This booklet is intended to provide employers in the food-processing industry with information to help reduce workplace injuries, particularly musculoskeletal disorders, through the implementation

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign a guide to best

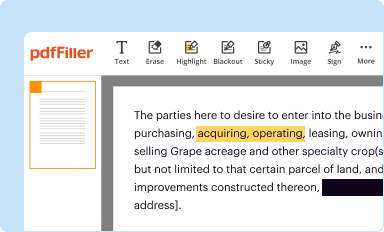

Edit your a guide to best form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

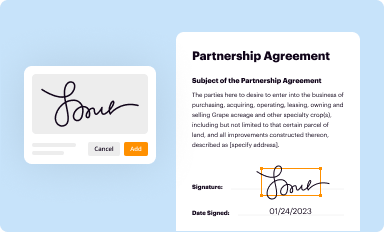

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

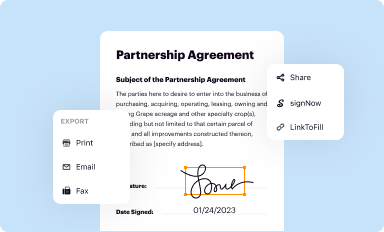

Share your form instantly

Email, fax, or share your a guide to best form via URL. You can also download, print, or export forms to your preferred cloud storage service.

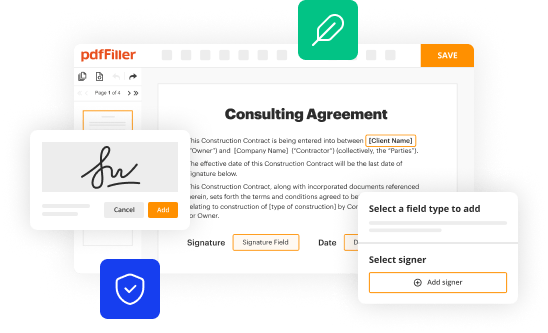

Editing a guide to best online

Follow the steps down below to benefit from the PDF editor's expertise:

1

Set up an account. If you are a new user, click Start Free Trial and establish a profile.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit a guide to best. Add and replace text, insert new objects, rearrange pages, add watermarks and page numbers, and more. Click Done when you are finished editing and go to the Documents tab to merge, split, lock or unlock the file.

4

Save your file. Select it from your list of records. Then, move your cursor to the right toolbar and choose one of the exporting options. You can save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud, among other things.

Dealing with documents is always simple with pdfFiller. Try it right now

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out a guide to best

How to fill out A Guide to Best Practices for the Food-Processing Industry

01

Gather necessary documents and materials related to your food processing operations.

02

Review the introduction section to understand the purpose of the guide.

03

Follow the step-by-step instructions provided in each section, focusing on key practices.

04

Complete the self-assessment checklists included to evaluate current processes.

05

Identify areas for improvement based on the recommendations provided.

06

Implement best practices and document changes made within your operation.

07

Continuously monitor and update your processes as necessary to ensure compliance with industry standards.

Who needs A Guide to Best Practices for the Food-Processing Industry?

01

Food processing facility operators and managers.

02

Quality assurance professionals within the food industry.

03

Regulatory agencies and compliance officers.

04

Consultants and trainers in food safety and quality management.

05

Students and educators in food science and industry-related courses.

Fill

form

: Try Risk Free

People Also Ask about

What are the 4 types of food processing?

Techniques used in food processing include pasteurization, fermentation, canning, freezing, and dehydration. Food processing makes food products more palatable and nutritious and allows for creation of a wide range of food items from basic ingredients, supporting both food diversity and accessibility in the market.

How to make SOP in food industry?

How to Develop and Implement SOPs in the Food Industry? Define the Scope and Purpose. Assemble an SOP Team. Conduct a Thorough Assessment. Provide Step-by-Step Instructions. Identify Hazards and Implement Control Measures. Train and Educate Employees. Monitor and Verify Compliance. Review and Update Regularly.

What are the four levels of food processing?

Monteiro 7 described a four‐tiered NOVA classification of foods 6 which include unprocessed/minimally processed foods (Group 1), processed culinary ingredients (Group 2), processed foods (Group 3) and ultra‐processed foods (Group 4).

What are the four main stages of food processing?

There are four stages involved in the process of deriving nutrients and energy from the food eaten. Ingestion, often known as bringing food into the system, is the initial step in the digestive process for animals that chew their food, followed by the stages of digestion, absorption, and finally, elimination.

What are the different types of food processing?

What are examples of food processing methods? Heating. Cooking impacts the amount of nutrients in our foods. Canning. Canning allows us to preserve excess harvest. Drying/dehydration. Drying removes the water content of food. Juicing. Fermentation. Freezing. Modified atmosphere packaging. Pasteurisation.

What are the 5S in the food industry?

Sort, straighten, shine, standardize, and sustain. 5S principles are based on the idea that a well organized and clean workplace increases employee satisfaction, promotes worker safety, and decreases product waste.

What are the 5 food processing methods?

5 traditional food processing techniques explained 1 Homogenisation. 2 Pasteurisation. 3 Canning. 4 Drying. 5 Smoking.

What are the 4 categories of processed foods?

The NOVA system, for example, has four food categories: (1) unprocessed or minimally processed foods, (2) processed culinary ingredients, (3) processed foods, and (4) ultra-processed foods.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is A Guide to Best Practices for the Food-Processing Industry?

A Guide to Best Practices for the Food-Processing Industry is a comprehensive resource designed to help food processing companies adhere to industry standards and best practices for food safety, quality assurance, and regulatory compliance.

Who is required to file A Guide to Best Practices for the Food-Processing Industry?

Food processing companies, including manufacturers, packagers, and distributors, are required to follow the guidelines set forth in A Guide to Best Practices for the Food-Processing Industry to ensure compliance with health regulations and safety standards.

How to fill out A Guide to Best Practices for the Food-Processing Industry?

To fill out A Guide to Best Practices for the Food-Processing Industry, companies should review the guidelines thoroughly, assess their current practices, and document compliance with specific sections related to food safety protocols, employee training, and facility sanitation.

What is the purpose of A Guide to Best Practices for the Food-Processing Industry?

The purpose of A Guide to Best Practices for the Food-Processing Industry is to provide food processors with a framework to achieve high standards of food safety and quality, reduce risks associated with foodborne illnesses, and maintain compliance with applicable regulations.

What information must be reported on A Guide to Best Practices for the Food-Processing Industry?

The information that must be reported includes details about food safety measures in place, employee training records, hazard analysis and critical control points (HACCP) plans, facility sanitation procedures, and any incidents of non-compliance or corrective actions taken.

Fill out your a guide to best online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

A Guide To Best is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.