Get the free DIMENSIONAL ENGINEERING

Show details

This document serves as a comprehensive guide on geometric dimensioning and tolerancing (GD&T), detailing various tolerances related to form, orientation, location, and runout, in accordance with

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign dimensional engineering

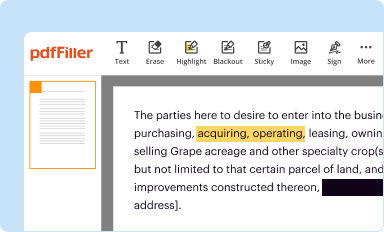

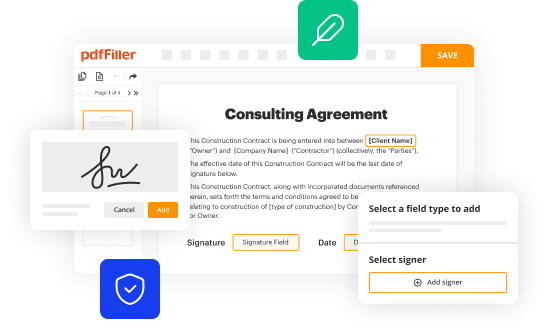

Edit your dimensional engineering form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

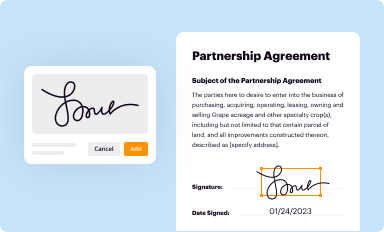

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

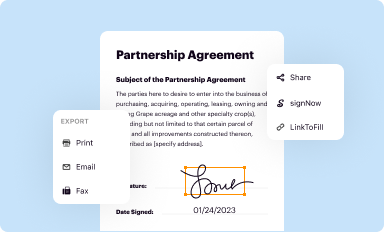

Share your form instantly

Email, fax, or share your dimensional engineering form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit dimensional engineering online

Use the instructions below to start using our professional PDF editor:

1

Set up an account. If you are a new user, click Start Free Trial and establish a profile.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit dimensional engineering. Add and replace text, insert new objects, rearrange pages, add watermarks and page numbers, and more. Click Done when you are finished editing and go to the Documents tab to merge, split, lock or unlock the file.

4

Get your file. Select the name of your file in the docs list and choose your preferred exporting method. You can download it as a PDF, save it in another format, send it by email, or transfer it to the cloud.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out dimensional engineering

How to fill out DIMENSIONAL ENGINEERING

01

Gather all necessary specifications and measurements of the project.

02

Identify the dimensional tolerances required for the components.

03

Utilize appropriate software or tools to create a dimensional layout.

04

Ensure all parts are measured accurately using calipers or similar tools.

05

Document each dimension in a clear and organized manner.

06

Review the dimensional data to ensure compliance with project requirements.

07

Submit the completed dimensional engineering documentation for approval.

Who needs DIMENSIONAL ENGINEERING?

01

Manufacturers looking to produce precise components.

02

Engineers and designers involved in product development.

03

Quality control teams to ensure product standards.

04

Construction firms requiring detailed dimensions for building plans.

05

Researchers requiring accurate measurements for experimental setups.

Fill

form

: Try Risk Free

People Also Ask about

What is a dimension in engineering?

Dimension — the numerical value that defines the size, shape, location, surface texture, or geometric characteristic of a feature. Basic dimension — a numerical value defining the theoretically exact size, location, or orientation relative to a coordinate system.

What do dimensional engineers do?

Your daily duties may involve analyzing data, identifying problems in the manufacturing process, and documenting case studies. You may also perform statistical reporting and use simulation tools for planning.

What is the dimensional engineering process?

A comprehensive dimensional engineering process enables fit, finish, and function to be analyzed. Multiple solutions can be tried through visual simulation then validated through automated as-built reporting. This “closed-loop” system drives product quality all the way from design engineering to production.

What is a dimension in data engineering?

In data warehousing, a dimension is a collection of reference information that supports a measurable event, such as a customer transaction. In this context, events are referred to as "facts." Dimensions provide the details necessary to understand and analyze a set of related facts.

What does a dimensional engineer do?

As a dimensional engineer, your primary responsibilities include designing components for the assembly process to increase productivity and safety. Your daily duties may involve analyzing data, identifying problems in the manufacturing process, and documenting case studies.

What is the dimensional engineering process?

A comprehensive dimensional engineering process enables fit, finish, and function to be analyzed. Multiple solutions can be tried through visual simulation then validated through automated as-built reporting. This “closed-loop” system drives product quality all the way from design engineering to production.

What is dimension engineering?

Dimensional engineering combines different aspects from the design, manufacturing, and metrology fields. I often define dimensional engineering as the study of how part level imperfections affect a product at the assembly level.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is DIMENSIONAL ENGINEERING?

Dimensional engineering is a field of engineering that focuses on analyzing and controlling the dimensions and tolerances of components and assemblies within manufacturing processes to ensure proper fit, function, and performance.

Who is required to file DIMENSIONAL ENGINEERING?

Individuals or organizations involved in the manufacturing or design of products that require adherence to specific dimensions and tolerances are generally required to file dimensional engineering assessments.

How to fill out DIMENSIONAL ENGINEERING?

To fill out dimensional engineering, one must provide accurate measurements, specify tolerances, and include any relevant design specifications or drawings that detail the required dimensions and their acceptable variances.

What is the purpose of DIMENSIONAL ENGINEERING?

The purpose of dimensional engineering is to ensure that all manufactured parts meet design specifications for size and fit, which helps minimize defects, improve interoperability, and enhance overall product quality.

What information must be reported on DIMENSIONAL ENGINEERING?

Information that must be reported includes the dimensions of parts, tolerances, measurements obtained during quality checks, deviations from standard specifications, and any relevant notes regarding the production process.

Fill out your dimensional engineering online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Dimensional Engineering is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.