Get the free Removing Contaminants from Silicon Wafers - volta byu

Show details

This thesis investigates methods for removing organic contaminants from silicon wafers to improve optical measurements critical for extreme ultraviolet (EUV) applications, including space-based astronomy

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign removing contaminants from silicon

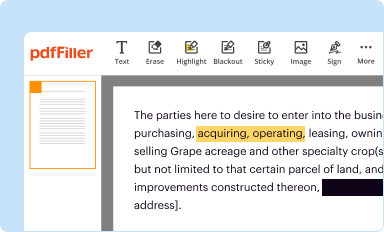

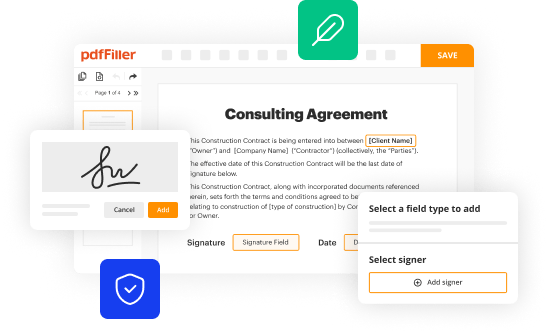

Edit your removing contaminants from silicon form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

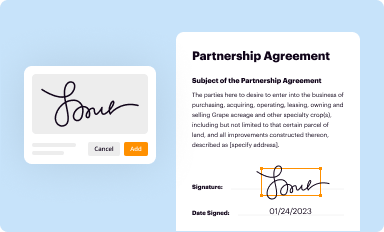

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

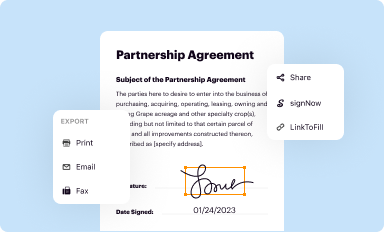

Share your form instantly

Email, fax, or share your removing contaminants from silicon form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit removing contaminants from silicon online

To use our professional PDF editor, follow these steps:

1

Create an account. Begin by choosing Start Free Trial and, if you are a new user, establish a profile.

2

Prepare a file. Use the Add New button to start a new project. Then, using your device, upload your file to the system by importing it from internal mail, the cloud, or adding its URL.

3

Edit removing contaminants from silicon. Rearrange and rotate pages, add new and changed texts, add new objects, and use other useful tools. When you're done, click Done. You can use the Documents tab to merge, split, lock, or unlock your files.

4

Get your file. When you find your file in the docs list, click on its name and choose how you want to save it. To get the PDF, you can save it, send an email with it, or move it to the cloud.

With pdfFiller, it's always easy to deal with documents. Try it right now

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out removing contaminants from silicon

How to fill out Removing Contaminants from Silicon Wafers

01

Gather necessary materials: cleaning solution, deionized water, and cleanroom wipes.

02

Inspect the silicon wafers for visible contaminants.

03

Immerse the wafers in the cleaning solution for the recommended time.

04

Rinse the wafers thoroughly with deionized water to remove the cleaning solution.

05

Use cleanroom wipes to gently dry the wafers, avoiding any scratches.

06

Inspect the wafers again under a microscope for any remaining contaminants.

07

If needed, repeat the cleaning process until the wafers are free from contaminants.

Who needs Removing Contaminants from Silicon Wafers?

01

Semiconductor manufacturers

02

Researchers in nanotechnology and materials science

03

Companies involved in solar cell production

04

Laboratories focusing on microelectronics and device fabrication

05

Quality control teams in semiconductor production facilities

Fill

form

: Try Risk Free

People Also Ask about

What is the contamination of wafers?

These contaminants may be physically adsorbed onto the wafer surface or may be chemically bound. For example, organic molecules from the cleanroom atmosphere may adsorb onto the wafer surface, while thin layers of oxidized Cu may result from the etching and post-etch cleaning of vias.

How do you clean silicon nitride wafers?

Overview: Silicon wafers are cleaned by a solvent clean, followed by a dionized water (DI) rinse, followed by an RCA clean and DI rinse, followed by an HF dip and DI rinse and blow dry. Parts of this (RCA, HF dip) are dangerous wetbench processes and requires qualification for dangerous wetbench processes.

How do you clean a silicon carbide wafer?

Heat the silicon carbide wafer in 30% hydrogen peroxide solution at 70°C for 3 minutes, take out the wafer and rinse the front and back sides with deionized water for 30 seconds each, and then soak the wafer in hydrofluoric acid solution at room temperature for 3 minutes.

What happens if contaminants are not removed from wafers?

Pre-diffusion cleaning is a critical process because particles or contaminants on the wafer surface are likely to be driven into the wafer, causing unpredictable electrical properties that result in defective or low-quality semiconductor output.

Why is wafer cleaning important?

The surface contaminants that may be present on a silicon wafer. Prior to a wafer's entry into the fabrication process, its surface must be cleaned to remove any adhering particles and organic/inorganic impurities. Silicon native oxide also needs to be removed.

What are the defects in silicon wafers?

Common Silicon Wafer Defects Scratches - Small scrapes in the surface layer of the wafer, caused by contact with manufacturing equipment or debris. These abrasions disrupt lithography patterns. Pits - Tiny missing spaces in the wafer surface that can harbor contamination. They transplant to devices.

What role does wafer cleaning play in preventing contamination and what specific methods are used to remove various types of contaminants from the wafer surface?

The wafer cleaning system is responsible for removing contaminants such as particles, organic residues, and metal ions from the surface of silicon wafers. Its effectiveness determines the performance and yield of the final semiconductor devices.

How do you clean a silicon wafer?

The process of cleaning Silicon Wafers involves using a deionized water bath. This water is highly acidic and must be free of sulfur and other chemicals. The water is essential for the proper functioning of the oxidized solution. It is used in the oxidizing treatment for silicon wafers.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is Removing Contaminants from Silicon Wafers?

Removing contaminants from silicon wafers refers to the process of eliminating impurities and unwanted particles that can affect the performance and quality of semiconductor devices manufactured on these wafers.

Who is required to file Removing Contaminants from Silicon Wafers?

Typically, manufacturers and facilities engaged in the production of semiconductor devices or silicon wafers are required to file information regarding the removal of contaminants.

How to fill out Removing Contaminants from Silicon Wafers?

Filling out the documentation for removing contaminants from silicon wafers usually involves providing details about the cleaning processes used, the types of contaminants present, and the methods employed to ensure compliance with industry standards.

What is the purpose of Removing Contaminants from Silicon Wafers?

The purpose of removing contaminants from silicon wafers is to enhance the quality and performance of semiconductor devices, ensuring they function reliably and efficiently in electronic applications.

What information must be reported on Removing Contaminants from Silicon Wafers?

The information that must be reported includes details about the types of contaminants detected, cleaning methods used, the effectiveness of the removal process, and any relevant data regarding compliance with safety and quality regulations.

Fill out your removing contaminants from silicon online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Removing Contaminants From Silicon is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.