Get the free WELDING AND METAL FABRICATION TECHNOLOGY ASSOCIATE OF - msubillings

Show details

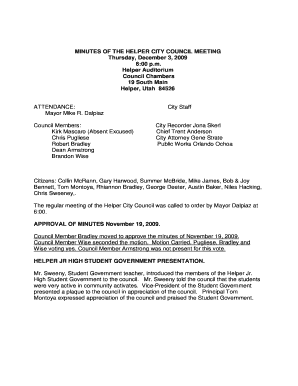

MONTANA STATE UNIVERSITY BILLINGS WELDING AND METAL FABRICATION TECHNOLOGY ASSOCIATE OF APPLIED SCIENCE ADVISING WORKSHEET 20142015 City College Jacket Student Central Phone: 4062473019 Fax: 4062473095

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign welding and metal fabrication

Edit your welding and metal fabrication form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your welding and metal fabrication form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit welding and metal fabrication online

Follow the guidelines below to take advantage of the professional PDF editor:

1

Log in to your account. Click on Start Free Trial and sign up a profile if you don't have one yet.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit welding and metal fabrication. Add and change text, add new objects, move pages, add watermarks and page numbers, and more. Then click Done when you're done editing and go to the Documents tab to merge or split the file. If you want to lock or unlock the file, click the lock or unlock button.

4

Save your file. Select it in the list of your records. Then, move the cursor to the right toolbar and choose one of the available exporting methods: save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud.

It's easier to work with documents with pdfFiller than you could have ever thought. You can sign up for an account to see for yourself.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out welding and metal fabrication

How to fill out welding and metal fabrication:

01

Start by acquiring the necessary knowledge and skills. Consider enrolling in a welding and metal fabrication program or seeking apprenticeships to gain hands-on experience in this field.

02

Familiarize yourself with different types of metals and welding techniques. Learn about various welding processes such as MIG welding, TIG welding, and arc welding. Understand the properties of different metals and which welding techniques are best suited for each.

03

Practice proper safety measures. Welding and metal fabrication involve working with high temperatures and potentially hazardous materials. Make sure to wear appropriate protective gear including welding helmets, gloves, and aprons. Ensure proper ventilation in the workspace to prevent exposure to harmful fumes.

04

Set up your workspace. Create a dedicated area for welding and metal fabrication that is well-ventilated, spacious, and equipped with necessary tools and equipment. This may include welding machines, grinders, cutting tools, and welding consumables such as filler rods and electrodes.

05

Prepare the metal for welding. This involves cleaning the metal surface to remove dirt, rust, or any other contaminants that may interfere with the welding process. Use a wire brush or grinder to clean the area to be welded.

06

Choose the appropriate welding technique and set up your welding equipment accordingly. Adjust the welding machine settings to match the metal thickness and desired weld strength. Ensure proper grounding and secure the metal in the correct position for welding.

07

Weld the metal pieces together. Follow the established welding technique, ensuring a steady hand and smooth movement. Control the heat input and welding speed to achieve a strong and aesthetically pleasing weld.

08

Inspect the weld for quality and integrity. Use visual and non-destructive testing methods to ensure the weld meets industry standards. Look for any defects or weaknesses that may compromise the structural integrity of the metal.

Who needs welding and metal fabrication?

01

Industries that heavily rely on metal structures and components such as construction, manufacturing, and automotive require welding and metal fabrication services. These industries need skilled welders and fabricators to join metals, fabricate custom parts, and repair damaged metal structures.

02

Professional welders and fabricators are also in demand for artistic and creative purposes. Artists, sculptors, and designers often require welding and metal fabrication skills to create unique metal artwork and installations.

03

Individuals who are passionate about DIY projects or want to repair or customize their own metal objects may also benefit from learning welding and metal fabrication. This can range from simple household repairs to building custom metal furniture or even constructing a small-scale metal structure.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is welding and metal fabrication?

Welding is a process of joining two or more metal pieces together using heat and pressure, whereas metal fabrication involves shaping metal into a desired form.

Who is required to file welding and metal fabrication?

Businesses or individuals who are involved in welding and metal fabrication are required to file appropriate documentation.

How to fill out welding and metal fabrication?

To fill out welding and metal fabrication forms, one must provide accurate information about the welding and fabrication activities being conducted.

What is the purpose of welding and metal fabrication?

The purpose of welding and metal fabrication is to create metal structures, components, or products for various industrial applications.

What information must be reported on welding and metal fabrication?

Information such as type of welding processes used, materials worked with, and safety precautions taken must be reported on welding and metal fabrication forms.

How do I complete welding and metal fabrication online?

Completing and signing welding and metal fabrication online is easy with pdfFiller. It enables you to edit original PDF content, highlight, blackout, erase and type text anywhere on a page, legally eSign your form, and much more. Create your free account and manage professional documents on the web.

How do I edit welding and metal fabrication in Chrome?

Install the pdfFiller Google Chrome Extension to edit welding and metal fabrication and other documents straight from Google search results. When reading documents in Chrome, you may edit them. Create fillable PDFs and update existing PDFs using pdfFiller.

Can I sign the welding and metal fabrication electronically in Chrome?

Yes. With pdfFiller for Chrome, you can eSign documents and utilize the PDF editor all in one spot. Create a legally enforceable eSignature by sketching, typing, or uploading a handwritten signature image. You may eSign your welding and metal fabrication in seconds.

Fill out your welding and metal fabrication online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Welding And Metal Fabrication is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.