UNIDO HACCP Generic Model Frozen Vegetables 2004-2025 free printable template

Show details

7) HACCP Generic Model: Frozen Vegetables Form 1 Product Description Product Name: Frozen Vegetables 1. Product Name(s) Frozen Peas 2. Important Product Characteristics (aw, pH, Salt, Preservatives,)

We are not affiliated with any brand or entity on this form

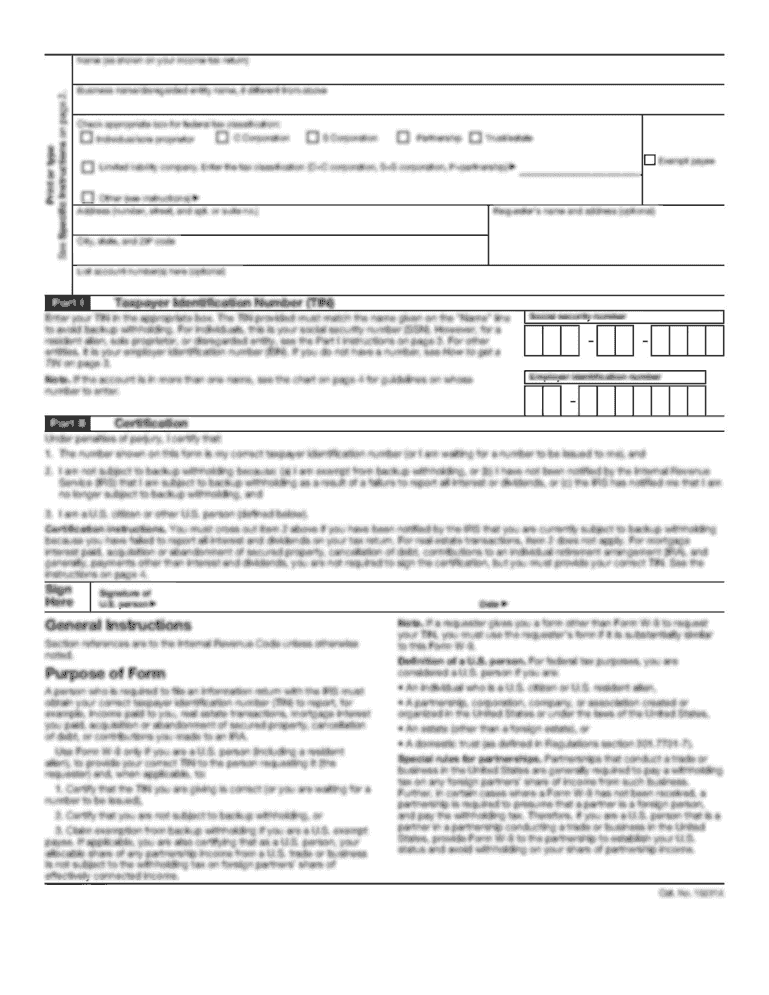

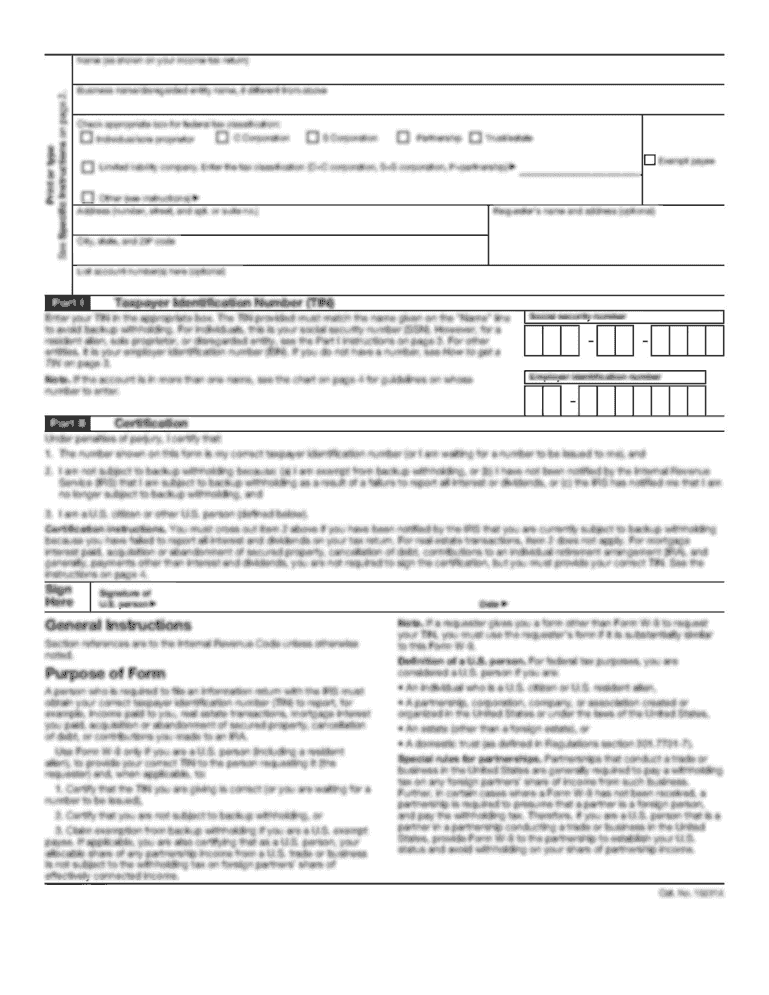

Get, Create, Make and Sign food product description example pdf form

Edit your haccp product description form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your UNIDO HACCP Generic Model Frozen Vegetables form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing UNIDO HACCP Generic Model Frozen Vegetables online

Follow the steps down below to take advantage of the professional PDF editor:

1

Check your account. If you don't have a profile yet, click Start Free Trial and sign up for one.

2

Simply add a document. Select Add New from your Dashboard and import a file into the system by uploading it from your device or importing it via the cloud, online, or internal mail. Then click Begin editing.

3

Edit UNIDO HACCP Generic Model Frozen Vegetables. Rearrange and rotate pages, add and edit text, and use additional tools. To save changes and return to your Dashboard, click Done. The Documents tab allows you to merge, divide, lock, or unlock files.

4

Save your file. Select it from your list of records. Then, move your cursor to the right toolbar and choose one of the exporting options. You can save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud, among other things.

Dealing with documents is always simple with pdfFiller. Try it right now

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out UNIDO HACCP Generic Model Frozen Vegetables

How to fill out UNIDO HACCP Generic Model Frozen Vegetables

01

Obtain the UNIDO HACCP Generic Model for Frozen Vegetables document.

02

Begin with the scope section and define the intended use of your frozen vegetable products.

03

Identify potential hazards by conducting a hazard analysis of the process.

04

Determine critical control points (CCPs) for each identified hazard.

05

Establish Critical Limits for each CCP, defining maximum and minimum parameters.

06

Develop monitoring procedures for each CCP to ensure compliance with Critical Limits.

07

Create corrective action plans for when monitoring indicates a deviation from Critical Limits.

08

Establish verification procedures to confirm the HACCP system is working effectively.

09

Maintain proper documentation and records for all procedures and activities.

10

Regularly review and update the HACCP plan to ensure it remains effective.

Who needs UNIDO HACCP Generic Model Frozen Vegetables?

01

Food manufacturers processing frozen vegetables.

02

Quality assurance teams in the food industry.

03

Regulatory bodies overseeing food safety standards.

04

Exporters of frozen vegetable products to ensure compliance with international food safety standards.

05

Training institutions teaching food safety practices.

Fill

form

: Try Risk Free

People Also Ask about

What is product description for HACCP?

In brief, the product description should include the name of the product, ingredients and composition, potential to support microbial growth (water activity [Aw], pH, etc.), brief details of the process and technology used in production, appropriate packaging and intended use, including target population.

What are the 7 principles of HACCP examples?

Seven basic principles are employed in the development of HACCP plans that meet the stated goal. These principles include hazard analysis, CCP identification, establishing critical limits, monitoring procedures, corrective actions, verification procedures, and record-keeping and documentation.

What is the first step in developing HACCP plan?

The first step in developing a HACCP plan is a hazard analysis. Hazard analysis thoroughly describes a hazard, including its type, severity, and the likelihood of occurrence. The proper analysis of hazards in your food business will determine the successful implementation of your HACCP plan.

What should be developed before implementing a HACCP plan?

Specific corrective actions should be developed in advance for each CCP and included in the HACCP plan. As a minimum, the HACCP plan should specify what is done when a deviation occurs, who is responsible for implementing the corrective actions, and that a record will be developed and maintained of the actions taken.

What is the importance of product description in HACCP?

PRODUCT DESCRIPTION The HACCP team must make a complete description of each food product - including all ingredients/processing methods/packaging materials/etc. used in the formulation of the product - to assist in the identification of all possible hazards associated with the product.

What is the purpose of describing the product and its use before developing a Haccp plan?

Task 2 - Describe the product Where appropriate, labelling information and an example of the label should be included. This information will help the HACCP team to identify 'real' hazards associated with the process.

What is the purpose of defining the scope and purpose in a HACCP plan?

2.2 Scope and Purpose The scope of the plan is important, as it is a reference point for many of the following steps involved in developing other HACCP plans in the business. The purpose of the food safety program should also be defined. The purpose is a statement of the reason the program has been put into practice.

Is step 2 of HACCP to describe your products and ingredients?

Step 2: Describe your products and ingredients (make a list) This list should include: product name, all ingredients, processing methods, preservation methods, packaging and storage requirements, shelf-life, allergen information, any legal requirements it complies with and the target consumer.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify UNIDO HACCP Generic Model Frozen Vegetables without leaving Google Drive?

You can quickly improve your document management and form preparation by integrating pdfFiller with Google Docs so that you can create, edit and sign documents directly from your Google Drive. The add-on enables you to transform your UNIDO HACCP Generic Model Frozen Vegetables into a dynamic fillable form that you can manage and eSign from any internet-connected device.

Can I create an eSignature for the UNIDO HACCP Generic Model Frozen Vegetables in Gmail?

When you use pdfFiller's add-on for Gmail, you can add or type a signature. You can also draw a signature. pdfFiller lets you eSign your UNIDO HACCP Generic Model Frozen Vegetables and other documents right from your email. In order to keep signed documents and your own signatures, you need to sign up for an account.

How do I complete UNIDO HACCP Generic Model Frozen Vegetables on an iOS device?

Download and install the pdfFiller iOS app. Then, launch the app and log in or create an account to have access to all of the editing tools of the solution. Upload your UNIDO HACCP Generic Model Frozen Vegetables from your device or cloud storage to open it, or input the document URL. After filling out all of the essential areas in the document and eSigning it (if necessary), you may save it or share it with others.

What is UNIDO HACCP Generic Model Frozen Vegetables?

The UNIDO HACCP Generic Model Frozen Vegetables is a standardized framework provided by the United Nations Industrial Development Organization (UNIDO) to help businesses implement Hazard Analysis and Critical Control Points (HACCP) principles specifically for frozen vegetable production.

Who is required to file UNIDO HACCP Generic Model Frozen Vegetables?

Food businesses involved in the production, processing, and distribution of frozen vegetables are required to file the UNIDO HACCP Generic Model to ensure compliance with food safety regulations.

How to fill out UNIDO HACCP Generic Model Frozen Vegetables?

To fill out the UNIDO HACCP Generic Model for Frozen Vegetables, businesses should assess potential hazards, establish critical control points, define monitoring procedures, and document all processes and corrective actions in accordance with the model's guidelines.

What is the purpose of UNIDO HACCP Generic Model Frozen Vegetables?

The purpose of the UNIDO HACCP Generic Model Frozen Vegetables is to ensure food safety throughout the frozen vegetable supply chain by identifying and controlling potential hazards that could affect product quality and consumer health.

What information must be reported on UNIDO HACCP Generic Model Frozen Vegetables?

The information that must be reported includes hazard identification, critical control points, monitoring procedures, corrective actions, verification methods, and documentation of the HACCP plan implementation.

Fill out your UNIDO HACCP Generic Model Frozen Vegetables online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

UNIDO HACCP Generic Model Frozen Vegetables is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.