Get the free Productivity Improvement in Lean Times for Precast and - pci

Show details

Focus on Plants, Plants, Plants Productivity Improvement in Lean Times for Precast and Prestressed Producers PLANT TOURS EXCHANGE OF IDEAS November 1013, 2015 Double tree by Hilton Hotel San Antonio

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign productivity improvement in lean

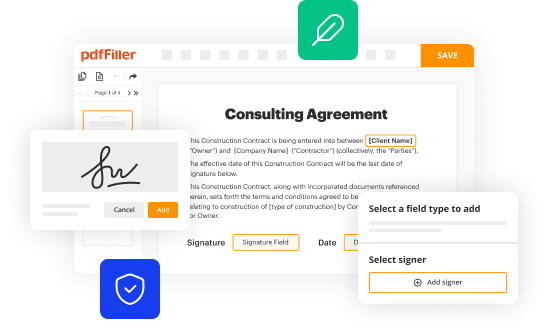

Edit your productivity improvement in lean form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your productivity improvement in lean form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit productivity improvement in lean online

Follow the steps down below to benefit from the PDF editor's expertise:

1

Log in. Click Start Free Trial and create a profile if necessary.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit productivity improvement in lean. Replace text, adding objects, rearranging pages, and more. Then select the Documents tab to combine, divide, lock or unlock the file.

4

Get your file. Select your file from the documents list and pick your export method. You may save it as a PDF, email it, or upload it to the cloud.

With pdfFiller, it's always easy to work with documents. Try it out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out productivity improvement in lean

How to fill out productivity improvement in lean?

01

Identify areas for improvement: Begin by conducting a thorough analysis of your current processes and operations. Look for bottlenecks, inefficiencies, and areas where productivity can be enhanced.

02

Set clear goals: Define specific and measurable goals that align with your overall business objectives. These goals should be focused on improving productivity and eliminating waste.

03

Create a plan: Develop a detailed plan outlining the steps and strategies you will implement to achieve your productivity improvement goals. This plan should include specific actions, timelines, and responsibilities.

04

Implement lean principles: Adopt lean principles and techniques such as value stream mapping, 5S, and just-in-time production. These methodologies aim to eliminate waste, streamline processes, and improve overall efficiency.

05

Train and engage employees: Provide training and education to your employees on lean methodologies and their role in productivity improvement. Encourage collaboration and empower individuals to identify and implement process improvements.

06

Monitor progress: Regularly track and measure your progress towards achieving your productivity improvement goals. Use key performance indicators (KPIs) to assess the effectiveness of your initiatives and make adjustments as needed.

07

Continuously improve: Adopt a culture of continuous improvement by regularly reviewing your processes, gathering feedback, and seeking opportunities for further optimization. Encourage innovation and reward employees for their contributions towards productivity enhancement.

Who needs productivity improvement in lean?

01

Small and medium-sized businesses: Lean practices can greatly benefit smaller businesses by enabling them to streamline operations, reduce waste, and improve overall productivity. This can help them compete effectively in the market and achieve sustainable growth.

02

Manufacturing companies: Lean principles were originally developed in the manufacturing sector and are still widely used in this industry. By implementing lean methodologies, manufacturing companies can enhance productivity, increase quality, and reduce costs.

03

Service organizations: Although lean concepts were initially applied in manufacturing, they can also be successfully implemented in service-oriented organizations. Companies in sectors such as healthcare, hospitality, and logistics can benefit from lean practices to eliminate waste, improve customer satisfaction, and optimize resource utilization.

04

Startups and entrepreneurs: Lean methodologies are particularly valuable for startups and entrepreneurs who are looking to maximize their limited resources and establish efficient operational processes from the outset. By adopting lean practices, they can accelerate growth and increase their chances of success.

05

Any organization striving for improvement: Regardless of the industry or size, any organization that aims to improve its productivity, reduce waste, and enhance overall efficiency can benefit from implementing lean practices. By embracing lean principles, these organizations can streamline their operations, increase profitability, and achieve a competitive edge in the marketplace.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I complete productivity improvement in lean online?

pdfFiller has made it easy to fill out and sign productivity improvement in lean. You can use the solution to change and move PDF content, add fields that can be filled in, and sign the document electronically. Start a free trial of pdfFiller, the best tool for editing and filling in documents.

How do I fill out productivity improvement in lean using my mobile device?

Use the pdfFiller mobile app to complete and sign productivity improvement in lean on your mobile device. Visit our web page (https://edit-pdf-ios-android.pdffiller.com/) to learn more about our mobile applications, the capabilities you’ll have access to, and the steps to take to get up and running.

How do I edit productivity improvement in lean on an iOS device?

Create, modify, and share productivity improvement in lean using the pdfFiller iOS app. Easy to install from the Apple Store. You may sign up for a free trial and then purchase a membership.

What is productivity improvement in lean?

Productivity improvement in lean refers to the continuous efforts to eliminate waste, reduce variability, and improve efficiency in all processes within an organization.

Who is required to file productivity improvement in lean?

All employees and departments within an organization are required to participate in and document productivity improvement in lean.

How to fill out productivity improvement in lean?

To fill out productivity improvement in lean, employees must track and measure key performance indicators, identify areas for improvement, implement changes, and monitor results.

What is the purpose of productivity improvement in lean?

The purpose of productivity improvement in lean is to increase efficiency, reduce waste, enhance quality, and ultimately improve the overall performance of an organization.

What information must be reported on productivity improvement in lean?

Information that must be reported on productivity improvement in lean includes data on productivity metrics, results of process improvements, and any obstacles or challenges faced during implementation.

Fill out your productivity improvement in lean online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Productivity Improvement In Lean is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.