Get the free Composite Fibers

Show details

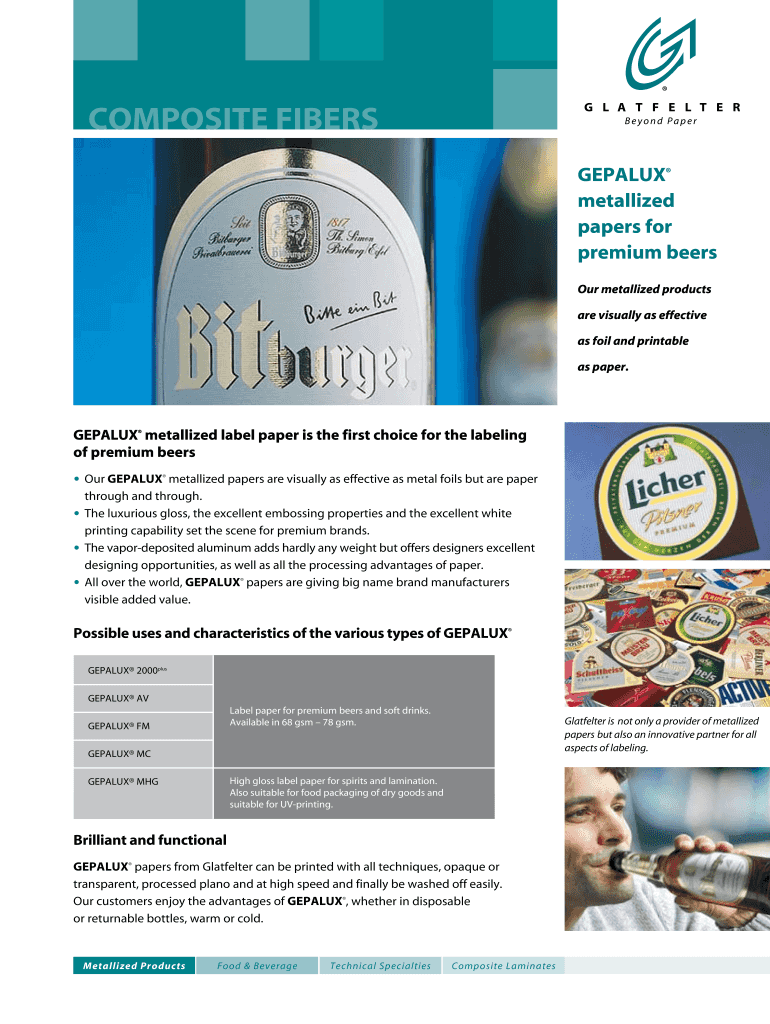

This document describes GEPALUX® metallized label papers that are suitable for labeling premium beers and other beverages, highlighting their visual effectiveness, excellent printing properties,

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign composite fibers

Edit your composite fibers form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your composite fibers form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing composite fibers online

Use the instructions below to start using our professional PDF editor:

1

Log in. Click Start Free Trial and create a profile if necessary.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit composite fibers. Replace text, adding objects, rearranging pages, and more. Then select the Documents tab to combine, divide, lock or unlock the file.

4

Get your file. When you find your file in the docs list, click on its name and choose how you want to save it. To get the PDF, you can save it, send an email with it, or move it to the cloud.

With pdfFiller, it's always easy to work with documents. Check it out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out composite fibers

How to fill out Composite Fibers

01

Gather all necessary materials including the composite fibers, measuring cup, and mixing tools.

02

Read the manufacturer's instructions for the specific composite fibers being used.

03

Measure the required amount of composite fibers according to the project specifications.

04

Mix the composite fibers with the appropriate resin or binder as directed.

05

Ensure an even distribution of the fibers in the mixture to achieve optimal strength and performance.

06

Apply the mixture onto the desired surface or mold using the recommended application techniques.

07

Allow the composite to cure as per the manufacturer's guidelines before further processing.

Who needs Composite Fibers?

01

Manufacturers of sporting goods and outdoor equipment.

02

Automotive and aerospace industries for lightweight and durable components.

03

Construction companies for building materials that enhance structural integrity.

04

Consumer goods companies looking for innovative materials in product design.

05

Researchers and students in materials science and engineering fields.

Fill

form

: Try Risk Free

People Also Ask about

What are fibrous composites?

Fibrous composites are materials consisting of lightweight, high modulus fibers inbedded in a surrounding material called the matrix. These composites have properties that vary with the direction of interest.

What is a composite fabric?

Fabric composites are defined as composite materials that incorporate knitted or woven fabrics as reinforcement within a continuous matrix, enhancing the material's strength and stiffness while providing a cost-effective manufacturing process with reduced waste.

What are 6 composite materials?

6 Types and Examples of Composite Materials Polymer Matrix Composites (PMCs) Metal Matrix Composites (MMCs) Ceramic Matrix Composites (CMCs) Carbon Matrix Composites (CAMCs) Polymer Matrix Composite with Ceramic Matrix. Hybrid Composites.

What is fibercomp?

A fiber composite refers to a modern composite material that combines strong fibers with a pliant matrix to create a material with high strength, stiffness, and low weight. The fibers are arranged in laminas or woven into mats to enhance their properties and provide a more isotropic material.

What are composite fibers?

Composite fibers are built up of two or more different components, which can be of inorganic and organic origin. These so-called organic/inorganic composite fibers are prominent in the literature and applications with cellulose as organic component are especially mentioned.

What are 5 examples of composite materials?

Composite materials Composite materialReinforcementMatrix Reinforced concrete Steel Concrete Fibreglass Glass fibres Polymer resin Carbon fibre reinforced polymer Carbon fibres Polymer resin Chipboard Wood chips Resin glue

What is a composite fiber?

Composite fibers are built up of two or more different components, which can be of inorganic and organic origin. These so-called organic/inorganic composite fibers are prominent in the literature and applications with cellulose as organic component are especially mentioned.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is Composite Fibers?

Composite fibers are materials made from combining different types of fibers to enhance their strength, durability, and functionality. They can include a mix of natural and synthetic fibers.

Who is required to file Composite Fibers?

Manufacturers and importers of textile products that include composite fibers are required to file Composite Fibers documentation with the appropriate regulatory authorities.

How to fill out Composite Fibers?

To fill out Composite Fibers documentation, provide detailed information about the types of fibers used, their percentages, and the fabric construction. Follow the guidelines set by the regulatory body.

What is the purpose of Composite Fibers?

The purpose of composite fibers is to create materials that benefit from the properties of different fibers, providing better performance, durability, and aesthetic qualities compared to single-fiber materials.

What information must be reported on Composite Fibers?

Reported information on Composite Fibers must include the fiber content percentages, the types of fibers used, manufacturing details, and any relevant safety and compliance information.

Fill out your composite fibers online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Composite Fibers is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.