Get the free 3 AXIS - CNC SUBMITTAL FORM - apbuffaloedu - ap buffalo

Show details

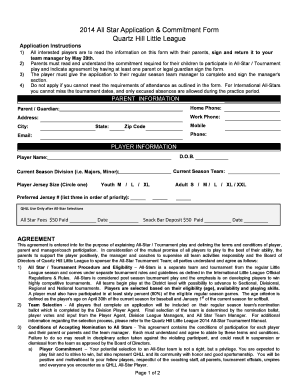

3 AXIS CNC SUBMITTAL FORM Complete student section of form, place with material in shop, submit Tool path or Rhino CAM file to the share drive CNC folder, and email notification to BFA buffalo.edu.

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign 3 axis - cnc

Edit your 3 axis - cnc form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your 3 axis - cnc form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing 3 axis - cnc online

To use the professional PDF editor, follow these steps below:

1

Register the account. Begin by clicking Start Free Trial and create a profile if you are a new user.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit 3 axis - cnc. Replace text, adding objects, rearranging pages, and more. Then select the Documents tab to combine, divide, lock or unlock the file.

4

Save your file. Select it from your records list. Then, click the right toolbar and select one of the various exporting options: save in numerous formats, download as PDF, email, or cloud.

pdfFiller makes dealing with documents a breeze. Create an account to find out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out 3 axis - cnc

How to fill out 3 axis - cnc:

01

Start by powering on the 3 axis CNC machine and ensuring that it is properly connected to a computer or control system.

02

Next, load the appropriate CNC program or design file onto the computer or control system. This program will contain the instructions for the machine to follow.

03

Make sure the material to be machined is securely fastened to the CNC machine's worktable. This can usually be done using clamps or other fixtures.

04

Use the CNC machine's control system to set the origin point or reference position for the machining process. This will determine where the CNC machine will start its movements.

05

Set the desired cutting parameters, such as the spindle speed, feed rate, and depth of cut. These settings will depend on the material being machined and the specific requirements of the job.

06

Once all the settings are in place, initiate the CNC machining process by starting the program or pressing the appropriate buttons on the control system.

07

Monitor the machining process carefully to ensure that everything is running smoothly. Make any necessary adjustments if needed.

08

When the machining process is complete, power off the CNC machine and clean up any debris or waste material from the work area.

Who needs 3 axis - cnc:

01

Manufacturers and industrial companies that require precision machining for various parts and components can benefit from using a 3-axis CNC machine. This technology allows for accurate and efficient production of complex shapes and designs.

02

Individuals or businesses involved in woodworking, metalworking, or prototyping can also find a 3-axis CNC machine useful. It provides the capability to create intricate and detailed cuts, carvings, or engravings.

03

Educational institutions, such as universities or technical schools, may use 3-axis CNC machines as part of their curriculum to train students in advanced manufacturing techniques.

04

Artists and designers who work with sculptures, models, or customized pieces can utilize a 3-axis CNC machine to bring their creations to life with precision and consistency.

05

Small or medium-sized businesses looking to streamline their production processes and increase efficiency can opt for a 3-axis CNC machine to automate tasks and reduce manual labor.

In summary, anyone involved in precision manufacturing, woodworking, metalworking, prototyping, education, art, design, or small/medium-sized businesses can benefit from using a 3-axis CNC machine. It offers accuracy, efficiency, and versatility in various applications.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit 3 axis - cnc online?

pdfFiller not only allows you to edit the content of your files but fully rearrange them by changing the number and sequence of pages. Upload your 3 axis - cnc to the editor and make any required adjustments in a couple of clicks. The editor enables you to blackout, type, and erase text in PDFs, add images, sticky notes and text boxes, and much more.

Can I sign the 3 axis - cnc electronically in Chrome?

Yes. You can use pdfFiller to sign documents and use all of the features of the PDF editor in one place if you add this solution to Chrome. In order to use the extension, you can draw or write an electronic signature. You can also upload a picture of your handwritten signature. There is no need to worry about how long it takes to sign your 3 axis - cnc.

Can I create an eSignature for the 3 axis - cnc in Gmail?

Create your eSignature using pdfFiller and then eSign your 3 axis - cnc immediately from your email with pdfFiller's Gmail add-on. To keep your signatures and signed papers, you must create an account.

What is 3 axis - cnc?

A 3 axis CNC machine is a machine tool that utilizes computer numerical control to move a cutting tool or workpiece along three separate axes to create complex shapes and cuts.

Who is required to file 3 axis - cnc?

Manufacturers or operators of CNC machines may be required to file 3 axis CNC reports depending on regulations or compliance requirements.

How to fill out 3 axis - cnc?

To fill out a 3 axis CNC report, details about the machine, its usage, and any relevant data must be accurately documented.

What is the purpose of 3 axis - cnc?

The purpose of filing a 3 axis CNC report is to ensure compliance with regulations, track machine usage, and monitor maintenance schedules.

What information must be reported on 3 axis - cnc?

Information such as machine specifications, operating hours, maintenance records, and any incidents involving the CNC machine may need to be reported.

Fill out your 3 axis - cnc online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

3 Axis - Cnc is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.