WI Industrial Air Power Air Compressor Maintenance Log 2011-2025 free printable template

Show details

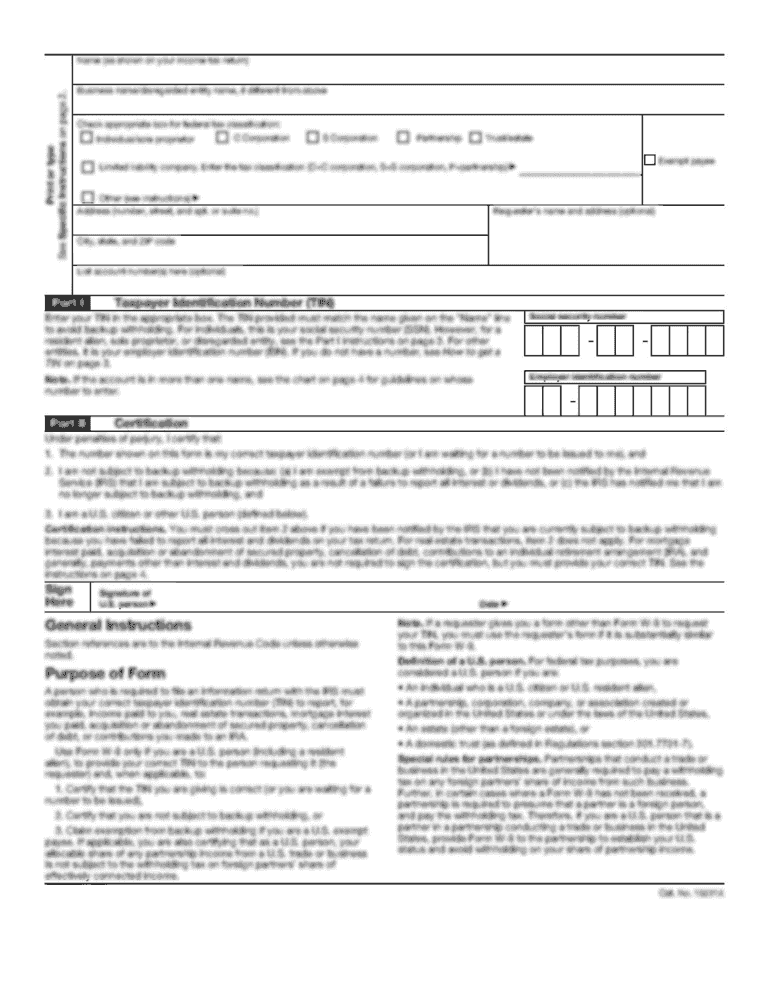

Air Compressor Maintenance Log

Make:Model:Serial No.:To use this maintenance log, check and sign in the appropriate boxes as routine maintenance is performed.

Record any notes or information that

pdfFiller is not affiliated with any government organization

Get, Create, Make and Sign air compressor log book format

Edit your air compressor daily log sheet form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your compressor log sheet form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing compressor log book form online

Follow the guidelines below to benefit from the PDF editor's expertise:

1

Log in. Click Start Free Trial and create a profile if necessary.

2

Simply add a document. Select Add New from your Dashboard and import a file into the system by uploading it from your device or importing it via the cloud, online, or internal mail. Then click Begin editing.

3

Edit compressor log book form. Rearrange and rotate pages, insert new and alter existing texts, add new objects, and take advantage of other helpful tools. Click Done to apply changes and return to your Dashboard. Go to the Documents tab to access merging, splitting, locking, or unlocking functions.

4

Get your file. When you find your file in the docs list, click on its name and choose how you want to save it. To get the PDF, you can save it, send an email with it, or move it to the cloud.

With pdfFiller, it's always easy to work with documents. Check it out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out compressor log book form

How to fill out WI Industrial Air Power Air Compressor Maintenance

01

Locate the air compressor maintenance manual provided by WI Industrial Air Power.

02

Gather necessary tools and materials, including oil, wrenches, and cleaning supplies.

03

Turn off the air compressor and disconnect it from the power source for safety.

04

Check and change the oil based on the manufacturer's recommendations.

05

Inspect and clean the air filters to ensure optimal airflow.

06

Examine all hoses and connections for wear and tear; replace as needed.

07

Verify that the pressure relief valves are functioning properly.

08

Test the safety features of the compressor before reactivation.

09

Reconnect the power source and run a test cycle to ensure everything is working correctly.

Who needs WI Industrial Air Power Air Compressor Maintenance?

01

Industries using air compressors for manufacturing and production processes.

02

Maintenance personnel responsible for equipment upkeep.

03

Facility managers overseeing operational efficiency and safety.

04

Technicians performing regular service checks on industrial machinery.

Fill

form

: Try Risk Free

People Also Ask about

What are the parts of compressor?

Cast iron and steel are the most prominent cylinder materials. Air Filters. Air filters are a regulatory maintenance and oversight component of a working compressor. Oil Filters. Bearings. Suction Valves. Discharge Valves. Motors.

What are the 2 types of compressors?

There are two basic types of air compressors: Positive displacement, and. Dynamic.

Which type air compressor is best?

Common sizes for two-stage industrial applications range between 75 hp and 250 hp. A two-stage double-acting reciprocating compressor is the most energy-efficient air compressor.

What is the main characteristic of a compressor?

A compressor increases the pressure of a fluid passing through it, so that the exit pressure is higher than the inlet pressure. Due to this property, compressors are used in a wide range of machines, such as refrigerators, cars, jet engines and industrial processes.

What is a 2 stage compressor used for?

Dual-stage air compressors produce higher air power, which makes them a better option for large-scale operations and continuous applications. However, two-stage compressors also cost more, which makes them better suited for factories and workshops than private use.

What is the type of compressor?

The four most common types of air compressors are: Rotary Screw Compressors. Reciprocating Air Compressors. Axial Compressors.

What is the parts of reciprocating compressor?

The major components of industrial type reciprocating compressor parts are: Compressor valves. Bearings. Piston.

What are the main types of air compressors?

There are two basic types of air compressors: Positive displacement, and. Dynamic.

What are 2 stage compressors?

Two-stage cooling means the air conditioner or heat pump has a compressor with two levels of operation: high for hot summer days and low for milder days. Since the low setting is adequate to meet household-cooling demands 80% of the time, a two-stage unit runs for longer periods and produces more even temperatures.

What are the parts of the air pump?

A simple reciprocating pump is commonly made up of a cylinder with an inlet, an outlet, and a piston within. The inlet and the outlet are used to direct the flow of air, while the piston is used to generate the flow of air. When the piston is pulled up, air gets sucked into the pump through the inlet.

What is the most important part of a compressor?

Both your inlet air filter and oil filter should be top of mind. For all that they do, they are one of the most essential air compressor parts.

What are good specs for an air compressor?

Instead of assessing an air compressor's capability by physical size, operators should look at how much air it delivers, measured in Cubic Feet Per Minute (CFM). As a guideline, most air compressors for powering tools fall in the 10 to 110 CFM range.

What are the two main types of compressor?

The two main types of compressors are dynamic and positive displacement. The positive displacement compressor is probably the one you're familiar with. It traps gas in a volume and then decreases that volume. The decrease in volume causes a rise in pressure.

What are the 4 types of air compressor?

The four most common types of air compressors are: Rotary Screw Compressors. Reciprocating Air Compressors. Axial Compressors. Centrifugal Compressors.

What are the compressor classification?

There are two basic types of air compressors: Positive displacement, and. Dynamic.

What are the compressor specifications?

Understanding Air Compressor Specifications The pounds per square inch gauge (PSIG) Cubic feet per minute (CFM) Horsepower. Size of the tank. The duty cycle. The type of motor it uses. Lubricated vs. oil-free systems. Rotary screw vs. reciprocating/piston systems.

What is a 4 stage air compressor?

Four-stage compression reduces the actual work needed to compress the air. The air leaving the first-, second-, and third-stage cylinders is water-cooled at constant pressure. A part of the heat is abstracted in the cylinders and in the inter-coolers.

What is compressor and its types?

Rotary screw, vane and reciprocating air compressors are the three most common types of air positive displacement compressors found in small and medium sized industries. Dynamic. Dynamic air compressors include centrifugal and axial machines, and are used in very large manufacturing facilities.

Our user reviews speak for themselves

Read more or give pdfFiller a try to experience the benefits for yourself

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify compressor log book form without leaving Google Drive?

By combining pdfFiller with Google Docs, you can generate fillable forms directly in Google Drive. No need to leave Google Drive to make edits or sign documents, including compressor log book form. Use pdfFiller's features in Google Drive to handle documents on any internet-connected device.

How do I edit compressor log book form in Chrome?

Install the pdfFiller Google Chrome Extension in your web browser to begin editing compressor log book form and other documents right from a Google search page. When you examine your documents in Chrome, you may make changes to them. With pdfFiller, you can create fillable documents and update existing PDFs from any internet-connected device.

How can I fill out compressor log book form on an iOS device?

pdfFiller has an iOS app that lets you fill out documents on your phone. A subscription to the service means you can make an account or log in to one you already have. As soon as the registration process is done, upload your compressor log book form. You can now use pdfFiller's more advanced features, like adding fillable fields and eSigning documents, as well as accessing them from any device, no matter where you are in the world.

What is WI Industrial Air Power Air Compressor Maintenance?

WI Industrial Air Power Air Compressor Maintenance refers to the systematic procedures and practices undertaken to ensure the optimal functioning and longevity of air compressors operated by WI Industrial Air Power.

Who is required to file WI Industrial Air Power Air Compressor Maintenance?

Individuals or businesses using WI Industrial Air Power air compressors are typically required to file maintenance records to ensure compliance with safety regulations and equipment performance standards.

How to fill out WI Industrial Air Power Air Compressor Maintenance?

To fill out the maintenance report, one should document the inspection date, description of maintenance performed, any findings or issues, and the name and signature of the technician who performed the maintenance.

What is the purpose of WI Industrial Air Power Air Compressor Maintenance?

The purpose of WI Industrial Air Power Air Compressor Maintenance is to ensure the reliability, efficiency, and safety of the air compressors, preventing potential breakdowns and prolonging their operational lifespan.

What information must be reported on WI Industrial Air Power Air Compressor Maintenance?

Required information includes maintenance dates, types of services performed, parts replaced, issues identified, and technician details.

Fill out your compressor log book form online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Compressor Log Book Form is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

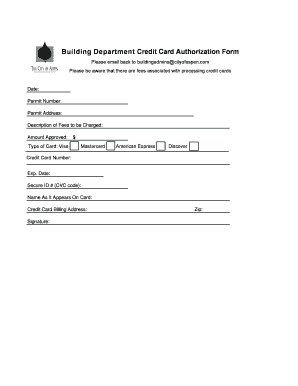

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.