Get the free MIG Welding InformationWhy Use MIG Welding?PraxairDirect.com

Show details

OM-239 988E 2009?08 Processes MIG (GMAC) Welding Flux Cored (FLAW) Welding Description Arc Welding Power Source And Wire Feeder Millermatic 211 Auto-Set w/MVP And M-10 Gun R Visit our website at www.MillerWelds.com

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign mig welding informationwhy use

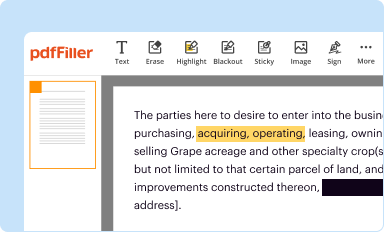

Edit your mig welding informationwhy use form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

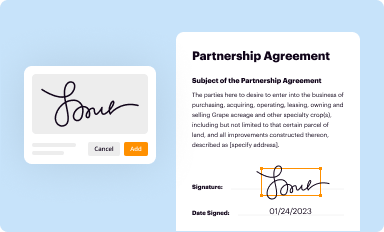

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

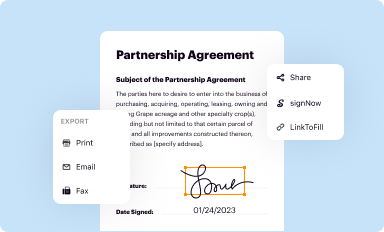

Share your form instantly

Email, fax, or share your mig welding informationwhy use form via URL. You can also download, print, or export forms to your preferred cloud storage service.

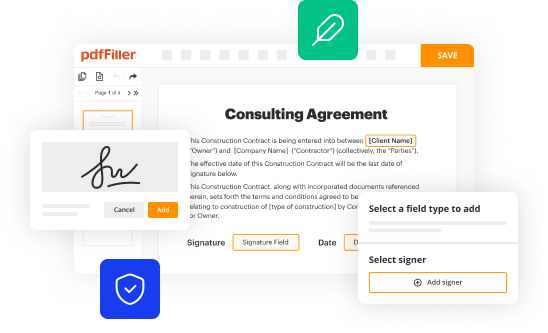

Editing mig welding informationwhy use online

Use the instructions below to start using our professional PDF editor:

1

Create an account. Begin by choosing Start Free Trial and, if you are a new user, establish a profile.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit mig welding informationwhy use. Text may be added and replaced, new objects can be included, pages can be rearranged, watermarks and page numbers can be added, and so on. When you're done editing, click Done and then go to the Documents tab to combine, divide, lock, or unlock the file.

4

Get your file. When you find your file in the docs list, click on its name and choose how you want to save it. To get the PDF, you can save it, send an email with it, or move it to the cloud.

With pdfFiller, it's always easy to deal with documents. Try it right now

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out mig welding informationwhy use

How to fill out MIG welding information and why use it?

01

Start by gathering all the necessary details about the welding project, such as the type of metal to be welded, the welding process to be used, and any specific requirements or specifications.

02

Fill out the MIG welding information form accurately, providing information about the welder's identification, equipment used, and the date and time of the welding activity.

03

Include details about the welding parameters, such as the voltage setting, wire feed speed, gas flow rate, and any specific techniques or procedures employed during the welding process.

04

Describe the type of shielding gas used in MIG welding, whether it is pure CO2 or a mixture of gases like argon and CO2. Indicate the gas flow rate and the reason for choosing a particular gas mix.

05

Specify the welding technique used, such as the travel speed, welding position, and any additional actions taken during welding, such as weaving motions or pulse welding.

Why use MIG welding information and who needs it?

01

MIG welding information is crucial for maintaining proper documentation of welding activities for quality control and audit purposes. It enables traceability and accountability, ensuring that welding procedures are followed correctly.

02

The information collected helps in evaluating the welding process, identifying any deviations or inconsistencies, and making necessary adjustments to achieve desirable weld quality.

03

Welding supervisors, quality control personnel, and welders themselves require MIG welding information to track and monitor the welding process, assess performance, and troubleshoot any issues that may arise during or after welding.

04

Engineers and designers also rely on MIG welding information to analyze weld joints, verify compliance with design specifications, and make informed decisions regarding material selection and weld joint design.

05

Overall, accurate and comprehensive MIG welding information promotes safety, quality, and efficiency in welding operations, ensuring that welds meet the required standards and specifications, and providing valuable insights for process improvement.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Where do I find mig welding informationwhy use?

The premium version of pdfFiller gives you access to a huge library of fillable forms (more than 25 million fillable templates). You can download, fill out, print, and sign them all. State-specific mig welding informationwhy use and other forms will be easy to find in the library. Find the template you need and use advanced editing tools to make it your own.

How do I edit mig welding informationwhy use in Chrome?

Get and add pdfFiller Google Chrome Extension to your browser to edit, fill out and eSign your mig welding informationwhy use, which you can open in the editor directly from a Google search page in just one click. Execute your fillable documents from any internet-connected device without leaving Chrome.

Can I edit mig welding informationwhy use on an iOS device?

Create, edit, and share mig welding informationwhy use from your iOS smartphone with the pdfFiller mobile app. Installing it from the Apple Store takes only a few seconds. You may take advantage of a free trial and select a subscription that meets your needs.

What is mig welding informationwhy use?

MIG welding refers to Metal Inert Gas welding, which is a welding process that uses a wire electrode to join metal pieces together. It is commonly used in industrial applications and offers advantages such as speed, ease of use, and high quality welds.

Who is required to file mig welding informationwhy use?

There is no specific requirement to file MIG welding information. However, welders and companies involved in MIG welding activities may need to keep records of their welding procedures and certifications to comply with industry standards and regulations.

How to fill out mig welding informationwhy use?

There is no specific form or template for filling out MIG welding information since it is not a standard reporting requirement. However, relevant information such as welding parameters, materials used, and inspection results should be documented and retained for quality control and compliance purposes.

What is the purpose of mig welding informationwhy use?

The purpose of documenting MIG welding information is to ensure quality control and compliance with industry standards. It allows for traceability of welds, facilitates troubleshooting or repairs, and provides a record for auditing or verification purposes.

What information must be reported on mig welding informationwhy use?

As there is no specific reporting requirement for MIG welding information, the information to be reported may vary depending on the specific project or regulatory requirements. However, typical information may include welding parameters (e.g., voltage, wire feed speed), materials used, pre-weld and post-weld inspections, and certification records of welders or welding procedures.

Fill out your mig welding informationwhy use online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Mig Welding Informationwhy Use is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.