Get the free Welding process evaluation report

Show details

Emerald Metals LLC Sample Welding Procedure Guide Book Company Date: Reference welding procedure evaluation report number gyyh22 Welding procedure guide book number WPS2010gyyh22 Welding method GTA+SMA

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign welding process evaluation report

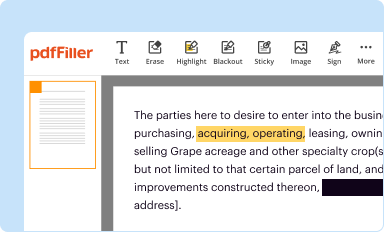

Edit your welding process evaluation report form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

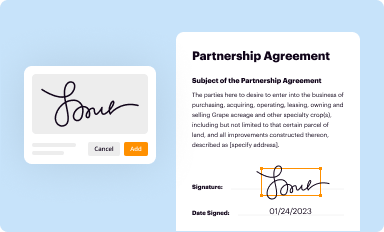

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your welding process evaluation report form via URL. You can also download, print, or export forms to your preferred cloud storage service.

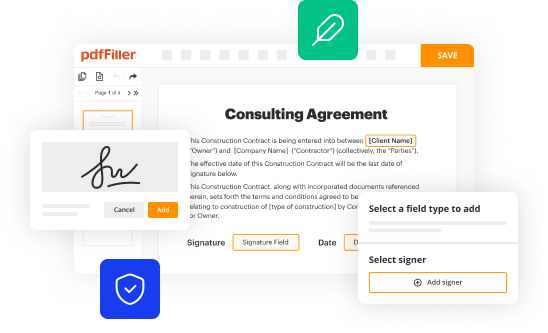

Editing welding process evaluation report online

To use the services of a skilled PDF editor, follow these steps:

1

Check your account. It's time to start your free trial.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit welding process evaluation report. Rearrange and rotate pages, add and edit text, and use additional tools. To save changes and return to your Dashboard, click Done. The Documents tab allows you to merge, divide, lock, or unlock files.

4

Save your file. Choose it from the list of records. Then, shift the pointer to the right toolbar and select one of the several exporting methods: save it in multiple formats, download it as a PDF, email it, or save it to the cloud.

With pdfFiller, it's always easy to work with documents. Check it out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out welding process evaluation report

How to fill out welding process evaluation report:

01

Start by recording the date and time of the evaluation at the top of the report.

02

Provide details about the welding process being evaluated, such as the type of welding technique used, the materials being welded, and any specific equipment or tools used.

03

Describe the specific parameters that are being evaluated, such as weld quality, joint integrity, adherence to industry standards, and overall welding performance.

04

Use appropriate measurement tools or instruments to accurately assess the parameters. This may include visual inspection, non-destructive testing, or mechanical testing.

05

Record the results of the evaluation, noting any deviations from the desired standards or any areas that require improvement.

06

Include any necessary observations or comments related to the welding process, such as potential safety hazards, equipment malfunctions, or operator errors.

07

Suggest corrective actions or recommendations to address any identified issues and improve the welding process.

08

Obtain the necessary signatures from relevant personnel, such as the welding inspector, the welder, and the supervisor.

09

Ensure that the completed report is securely stored for future reference and compliance purposes.

Who needs welding process evaluation report?

01

Welding inspectors: They need the evaluation report to assess the quality and compliance of the welding process, and to ensure it meets industry standards.

02

Welders: They may need the report to identify areas of improvement, learn from any mistakes or deviations, and enhance their welding skills.

03

Supervisors or managers: They rely on the evaluation report for gauging the overall performance of the welding process, making decisions on process improvement or training needs, and managing quality control measures.

04

Clients or customers: They may request the evaluation report to ensure that the welding process used meets their specific requirements, quality standards, or safety regulations.

05

Regulatory bodies or industry authorities: They may require the evaluation report to verify compliance with applicable codes, standards, or regulations.

06

Safety personnel: They may use the evaluation report to identify and rectify any potential safety hazards related to the welding process.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send welding process evaluation report to be eSigned by others?

To distribute your welding process evaluation report, simply send it to others and receive the eSigned document back instantly. Post or email a PDF that you've notarized online. Doing so requires never leaving your account.

How do I edit welding process evaluation report online?

With pdfFiller, it's easy to make changes. Open your welding process evaluation report in the editor, which is very easy to use and understand. When you go there, you'll be able to black out and change text, write and erase, add images, draw lines, arrows, and more. You can also add sticky notes and text boxes.

Can I create an eSignature for the welding process evaluation report in Gmail?

Use pdfFiller's Gmail add-on to upload, type, or draw a signature. Your welding process evaluation report and other papers may be signed using pdfFiller. Register for a free account to preserve signed papers and signatures.

What is welding process evaluation report?

The welding process evaluation report is a document that assesses and records the various aspects of welding processes used in a particular project or operation.

Who is required to file welding process evaluation report?

Welding inspectors, supervisors, or anyone responsible for overseeing welding operations may be required to file the welding process evaluation report.

How to fill out welding process evaluation report?

To fill out the welding process evaluation report, one must accurately document the welding processes used, equipment specifications, welding personnel qualifications, and any relevant quality control measures.

What is the purpose of welding process evaluation report?

The purpose of the welding process evaluation report is to ensure that welding operations are conducted in accordance with industry standards and regulations to maintain safety and quality.

What information must be reported on welding process evaluation report?

Information such as welding specifications, procedures, pre-qualification records of welders, welding inspection results, and any deviations from the welding procedures must be reported on the welding process evaluation report.

Fill out your welding process evaluation report online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Welding Process Evaluation Report is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.