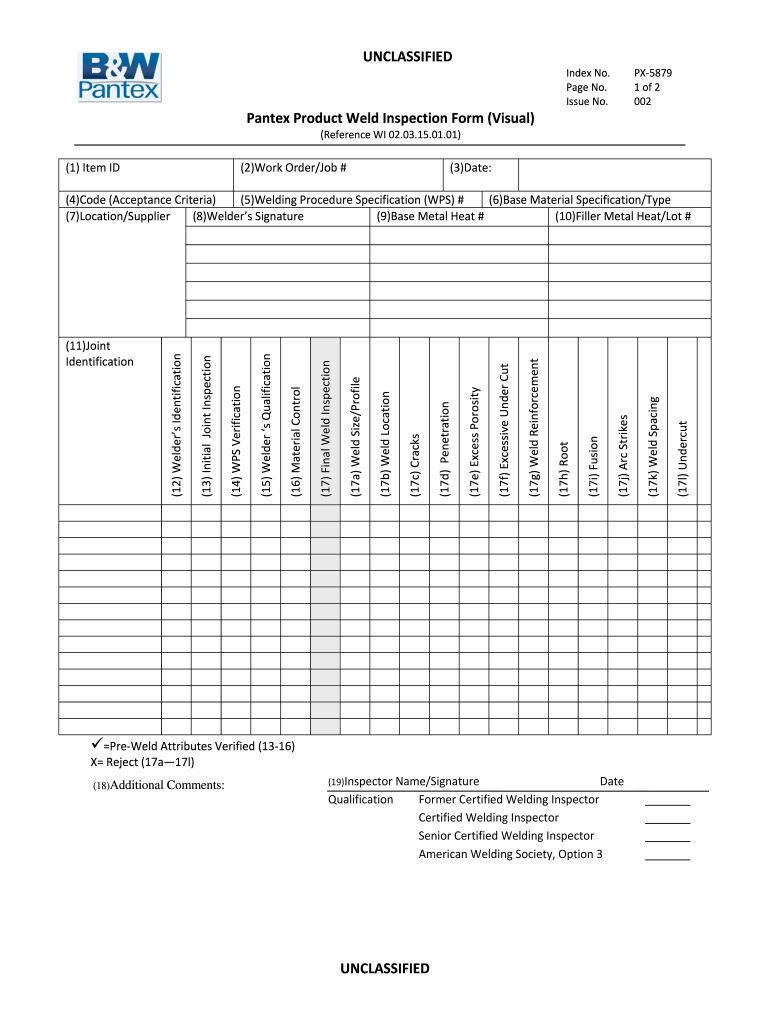

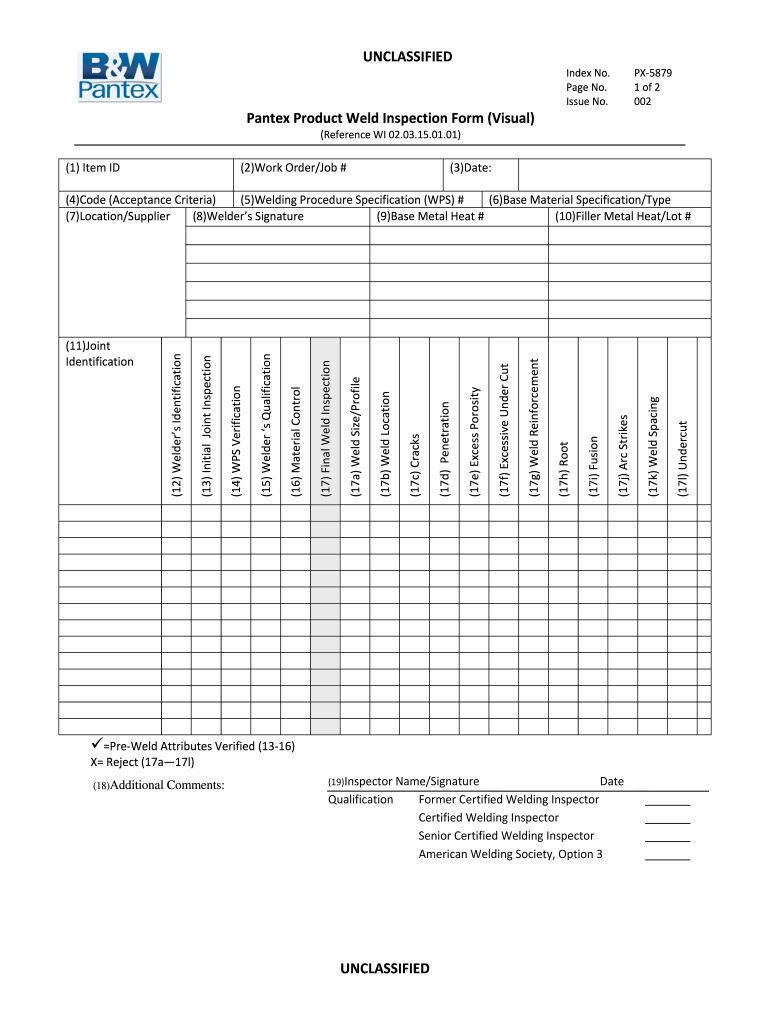

Pantex PX-5879 free printable template

Show details

UNCLASSIFIED Index No. Page No. Issue No. PX 5879 1 of 2 002 Panted Product Weld Inspection Form (Visual) (Reference WI 02.03.15.01.01) PRE Weld Attributes Verified (13 16) X Reject (17a 17l) (18)Additional

pdfFiller is not affiliated with any government organization

Get, Create, Make and Sign welding inspection report format pdf

Edit your arc inspection report form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your welding visual inspection report pdf form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing welding inspection forms pdf online

Follow the guidelines below to use a professional PDF editor:

1

Log into your account. If you don't have a profile yet, click Start Free Trial and sign up for one.

2

Simply add a document. Select Add New from your Dashboard and import a file into the system by uploading it from your device or importing it via the cloud, online, or internal mail. Then click Begin editing.

3

Edit welding inspection report example form. Add and replace text, insert new objects, rearrange pages, add watermarks and page numbers, and more. Click Done when you are finished editing and go to the Documents tab to merge, split, lock or unlock the file.

4

Get your file. When you find your file in the docs list, click on its name and choose how you want to save it. To get the PDF, you can save it, send an email with it, or move it to the cloud.

pdfFiller makes dealing with documents a breeze. Create an account to find out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out weld inspection report form

How to fill out Pantex PX-5879

01

Obtain the Pantex PX-5879 form from the Pantex website or your designated office.

02

Read the instructions carefully to understand the required information.

03

Fill in your personal information, such as name, address, and contact details, in the designated fields.

04

Provide any necessary identification numbers or codes as required.

05

Complete the section that details the purpose of the form or the request being made.

06

If applicable, include any supporting documents or additional information as indicated on the form.

07

Review the completed form for accuracy and completeness.

08

Sign and date the form where required.

09

Submit the form as instructed, either electronically or in person.

Who needs Pantex PX-5879?

01

Individuals or organizations seeking access to specific Pantex information.

02

Employees of Pantex who need to complete internal paperwork.

03

Contractors working with Pantex that require documentation.

04

Researchers requiring data from Pantex for studies or analysis.

Fill

welding inspection report

: Try Risk Free

People Also Ask about welding inspection form

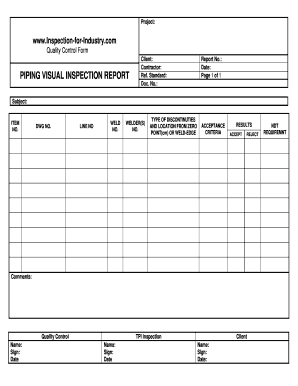

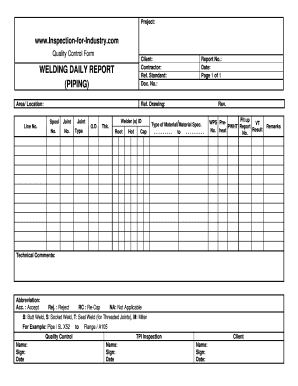

How do you visually inspect welds?

Visual Inspection During Welding Check electrodes for size, type and storage (low hydrogen electrodes are kept in a stabilizing oven) Watch root pass for susceptibility to cracking. Inspect each weld pass. Look for undercut and required contour. Check for craters that need to be filled. Check weld sequence and size.

What do you look for when visually inspecting a weld?

The basic method of checking the quality of a weld is to inspect it for any flaws visually. Look for any cracks, beads, bends, craters, excessive reinforcements, or other flaws and inform any concerned authorities about it.

What are some items that must be considered in visual examination after welding?

Check that all parameters stated in the Welding Procedure Specification are being followed. These parameters include items such as wire feed speed, voltage, electrical stickout, welding technique, welding progression, travel and push angles, shielding gas, adequate preheat and interpass temperature (if required), etc.

Which check is included in visual inspection during the welding?

Prior to welding, the visual welding inspector checks the material for quality, type, size, cleanliness, flatness, straight line and dimensional accuracy then when the joint is prepared for welding it can be checked for alignment, fit up and correct joint preparation.

What is the standard for visual inspection of welds?

ISO 17637 is an International Standard that specifies the visual testing of fusion welds in metallic materials. It may also be applied to visual testing of the joint prior to welding.

What should I inspect after welding?

Inspection After Welding Check weld against code and standards. Check size with gauges and prints. Check finish and contour. Check for cracks against standards. Look for overlap. Check undercut. Determine if spatter is at acceptable levels.

Our user reviews speak for themselves

Read more or give pdfFiller a try to experience the benefits for yourself

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I execute welding inspection checklist online?

pdfFiller has made filling out and eSigning welding reports easy. The solution is equipped with a set of features that enable you to edit and rearrange PDF content, add fillable fields, and eSign the document. Start a free trial to explore all the capabilities of pdfFiller, the ultimate document editing solution.

How do I edit welding report format online?

The editing procedure is simple with pdfFiller. Open your welding visual inspection checklist in the editor, which is quite user-friendly. You may use it to blackout, redact, write, and erase text, add photos, draw arrows and lines, set sticky notes and text boxes, and much more.

Can I create an electronic signature for signing my visual welding inspection report in Gmail?

Use pdfFiller's Gmail add-on to upload, type, or draw a signature. Your weld visual inspection report and other papers may be signed using pdfFiller. Register for a free account to preserve signed papers and signatures.

What is Pantex PX-5879?

Pantex PX-5879 is a specific form used by the Pantex Plant for reporting and tracking certain types of activities and data related to operations.

Who is required to file Pantex PX-5879?

Individuals or entities involved in operations at the Pantex Plant that meet specific criteria set by the management are required to file Pantex PX-5879.

How to fill out Pantex PX-5879?

To fill out Pantex PX-5879, follow the guidelines provided in the accompanying instructions, ensuring all sections are completed accurately and all required data is included.

What is the purpose of Pantex PX-5879?

The purpose of Pantex PX-5879 is to standardize the reporting of operational data and activities to ensure compliance with regulatory and operational requirements.

What information must be reported on Pantex PX-5879?

The information required on Pantex PX-5879 typically includes operational metrics, safety reviews, compliance checks, and any incidents or anomalies encountered during operations.

Fill out your Pantex PX-5879 online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Visual Inspection Report Welding is not the form you're looking for?Search for another form here.

Keywords relevant to welding inspection procedure pdf

Related to welding test report

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.