Get the free NAV 30 - FORGING PROCESS

Show details

This document is an audit checklist for the forging process, outlining administrative information, technical concerns, known process problems, and evaluation criteria to ensure quality control in

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign nav 30 - forging

Edit your nav 30 - forging form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

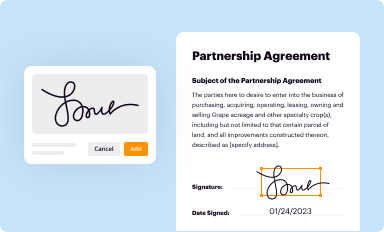

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

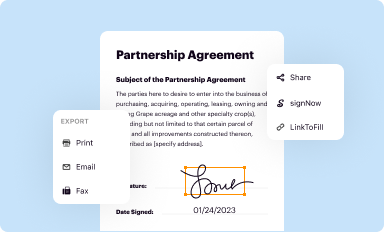

Share your form instantly

Email, fax, or share your nav 30 - forging form via URL. You can also download, print, or export forms to your preferred cloud storage service.

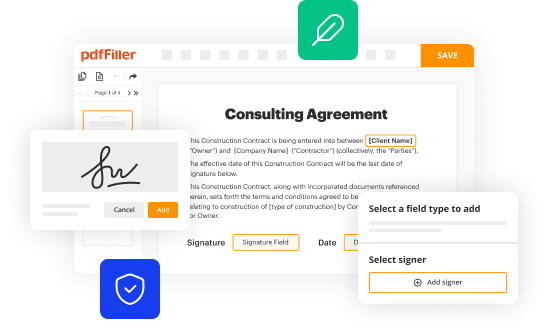

How to edit nav 30 - forging online

To use the services of a skilled PDF editor, follow these steps:

1

Register the account. Begin by clicking Start Free Trial and create a profile if you are a new user.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit nav 30 - forging. Add and replace text, insert new objects, rearrange pages, add watermarks and page numbers, and more. Click Done when you are finished editing and go to the Documents tab to merge, split, lock or unlock the file.

4

Save your file. Select it from your records list. Then, click the right toolbar and select one of the various exporting options: save in numerous formats, download as PDF, email, or cloud.

Dealing with documents is always simple with pdfFiller.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out nav 30 - forging

How to fill out NAV 30 - FORGING PROCESS

01

Step 1: Obtain a copy of the NAV 30 form for the forging process.

02

Step 2: Begin by filling out the top section with identifying information about the batch being forged.

03

Step 3: Provide details about the materials used in the forging process.

04

Step 4: Record the temperature and any specific conditions required during forging.

05

Step 5: Include information on the tools and equipment utilized in the process.

06

Step 6: Fill in any safety measures taken during the forging process.

07

Step 7: Review the completed form for accuracy and completeness before submission.

Who needs NAV 30 - FORGING PROCESS?

01

Manufacturers engaged in forging operations.

02

Quality assurance teams overseeing the forging process.

03

Regulatory bodies requiring documentation of forging activities.

04

Employees involved in training and safety audits related to forging.

Fill

form

: Try Risk Free

People Also Ask about

What is the process of forging?

In this process, a metal is shaped through hammering, pressing, or rolling. A hammer or die is used to impart compressive forces on the metal. Carbon, alloy, and stainless steel are frequently used in forging. Aluminum, brass, and copper, which are very soft metals, can also be forged.

Which is better hot forging or cold forging?

Read Cold Forging Process Vs Hot Forging ValueHot ForgingCold Forging Force Required Because the Metal is Softer and More Flexible, Less Force is Needed. High Force Needed Because of the Harder Material Dimensional Accuracy Good Accuracy, Although Further Finishing Might Be Necessary Extreme Precision and Close Tolerances9 more rows

What are the four steps of forging?

Forging Process Steps Die Design and Manufacturing. Modern forging processes use dies to enhance the accuracy, precision and speed of parts produced. Billet/Ingot Preparation. Heating. Forging. Heat Treatment. Cooling. Finishing. Hot Forging.

What are the four types of forging?

Four types of forging manufacturing processes are commonly used to shape metal parts. These metal forging processes include impression die forging (closed die), open die forging, cold forging, and seamless rolled ring forging.

What are the 5 forging operations?

Common forging processes include: roll forging, swaging, cogging, open-die forging, impression-die forging (closed die forging), press forging, cold forging, automatic hot forging and upsetting.

What are the various 5 steps in the forging process?

Forging Process Steps Die Design and Manufacturing. Modern forging processes use dies to enhance the accuracy, precision and speed of parts produced. Billet/Ingot Preparation. Heating. Forging. Heat Treatment. Cooling. Finishing. Hot Forging.

What are the 4 types of forging?

Four types of forging manufacturing processes are commonly used to shape metal parts. These metal forging processes include impression die forging (closed die), open die forging, cold forging, and seamless rolled ring forging.

What is forging process pdf?

Forging is a bulk forming process where metal is deformed into shaped components. ▪ It can be performed cold, warm, or hot. ▪ With warm and hot forging, there is a required preheating operation.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is NAV 30 - FORGING PROCESS?

NAV 30 - FORGING PROCESS is a form used to report and document the forging process within a specified timeframe in the naval and industrial sectors, detailing the production procedures and quality assurance measures.

Who is required to file NAV 30 - FORGING PROCESS?

Manufacturers and contractors involved in the forging of materials for naval applications are required to file NAV 30 - FORGING PROCESS.

How to fill out NAV 30 - FORGING PROCESS?

To fill out NAV 30 - FORGING PROCESS, provide necessary details such as company information, production data, quality control measures, and any specific forging techniques used.

What is the purpose of NAV 30 - FORGING PROCESS?

The purpose of NAV 30 - FORGING PROCESS is to ensure compliance with manufacturing standards, enhance oversight of production quality, and facilitate traceability of forged materials in naval applications.

What information must be reported on NAV 30 - FORGING PROCESS?

The information that must be reported includes details about the forging process, production dates, quality assurance results, any non-conformities observed, and the signatures of responsible personnel.

Fill out your nav 30 - forging online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Nav 30 - Forging is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.