Get the free SIMATIC PCS 7 Advanced ES

Show details

本文主要介绍如何利用 SIMATIC PCS 7 Advanced Engineering System (AdvES) 进行高效的工程组态,包括项目创建、数据导入、组态调整以及与其他系统的数据交换。

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign simatic pcs 7 advanced

Edit your simatic pcs 7 advanced form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your simatic pcs 7 advanced form via URL. You can also download, print, or export forms to your preferred cloud storage service.

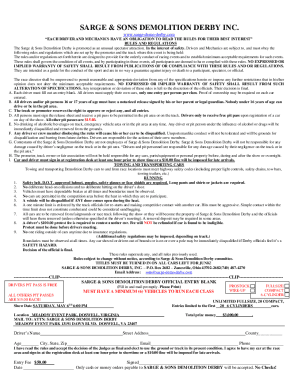

How to edit simatic pcs 7 advanced online

Follow the guidelines below to take advantage of the professional PDF editor:

1

Set up an account. If you are a new user, click Start Free Trial and establish a profile.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit simatic pcs 7 advanced. Add and change text, add new objects, move pages, add watermarks and page numbers, and more. Then click Done when you're done editing and go to the Documents tab to merge or split the file. If you want to lock or unlock the file, click the lock or unlock button.

4

Get your file. Select the name of your file in the docs list and choose your preferred exporting method. You can download it as a PDF, save it in another format, send it by email, or transfer it to the cloud.

pdfFiller makes dealing with documents a breeze. Create an account to find out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

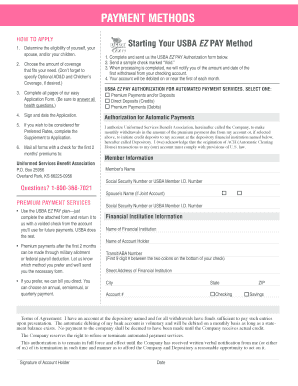

How to fill out simatic pcs 7 advanced

How to fill out SIMATIC PCS 7 Advanced ES

01

Launch the SIMATIC PCS 7 Advanced ES application.

02

Create a new project or open an existing project.

03

Specify the project settings, including hardware configuration and software options.

04

Add necessary components to your project, such as process objects, libraries, and control strategies.

05

Configure the communication settings for your hardware and PLCs.

06

Develop process automation logic using the available programming languages.

07

Set up visualization elements for monitoring the process.

08

Validate the project for errors and ensure all configurations are correct.

09

Compile the project to generate the necessary runtime files.

10

Download the project to the target hardware and perform testing.

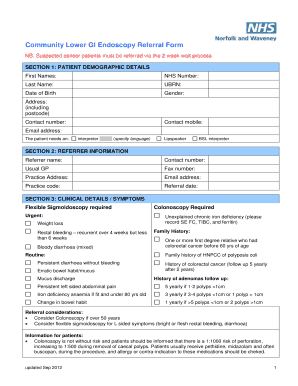

Who needs SIMATIC PCS 7 Advanced ES?

01

Industrial automation engineers and technicians.

02

Process control system designers.

03

Plant managers and operators.

04

Companies in manufacturing and process industries.

05

Educational institutions teaching automation technologies.

Fill

form

: Try Risk Free

People Also Ask about

What is the difference between WinCC and PCS7?

PCS7 and WinCC are both Siemens products, but differ in their functionality. PCS7 is a complete process control system (DCS) that integrates both automation and process visualisation and is suitable for complex industrial applications. WinCC is SCADA software for visualising and monitoring processes.

What are the benefits of PCS 7?

SIMATIC PCS 7: Revolutionizing Industrial Control Systems Scalability and Flexibility: One of the standout features of SIMATIC PCS 7 is its scalability. Integration: Redundancy and Reliability: Engineering Efficiency: Advanced Process Control: Increased Productivity: Cost Reduction: Compliance and Safety:

What is the difference between WinCC and PCS 7?

PCS7 and WinCC are both Siemens products, but differ in their functionality. PCS7 is a complete process control system (DCS) that integrates both automation and process visualisation and is suitable for complex industrial applications. WinCC is SCADA software for visualising and monitoring processes.

What is PCS 7 in Siemens?

PCS 7 (Process Control System 7) was developed by Siemens AG. The PCS 7 is used for process control and supervision in various industrial sectors, including oil and gas, power, water and wastewater, chemical, pharmaceutical, food and beverage, and more.

What is the difference between PCS7 and S7?

PCS7 is a set of "high level" tools to program the S7-400 controllers. Broadly speaking this means you have two options to configure/program the S7-400 PLC's. One is to buy just STEP7 and create a (low level) S7 program.

What is the difference between PLC and PCS7?

A PLC is still used in conjunction with the process control system, but PCS7 is used to build the control software and interrelations. PCS7 is more likely to replace a system HMI than the PLC. PCS7 uses WinCC to provide a SCADA solution for supervisory control and the acquisition of data for a process environment.

What is the difference between PLC and PCS 7?

A PLC is still used in conjunction with the process control system, but PCS7 is used to build the control software and interrelations. PCS7 is more likely to replace a system HMI than the PLC. PCS7 uses WinCC to provide a SCADA solution for supervisory control and the acquisition of data for a process environment.

What is SIMATIC PCS 7?

SIMATIC PCS 7 is based on PROFINET, the world's leading industrial Ethernet standard. PROFINET plays a key role in the digital transformation of the process industries, providing the prerequisites for powerful, plant-wide communication in real time – which is indispensable in the era of Big Data.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

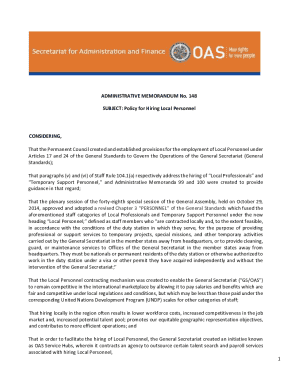

What is SIMATIC PCS 7 Advanced ES?

SIMATIC PCS 7 Advanced Engineering System (ES) is a comprehensive process control system designed for automation and control of industrial processes, allowing efficient management and optimization of operations.

Who is required to file SIMATIC PCS 7 Advanced ES?

Entities or organizations that utilize the SIMATIC PCS 7 system in their industrial processes and require a structured method for process control documentation are required to file the SIMATIC PCS 7 Advanced ES.

How to fill out SIMATIC PCS 7 Advanced ES?

To fill out SIMATIC PCS 7 Advanced ES, users should gather the necessary process data, utilize the software tools provided within the PCS 7 environment, and follow the guidelines and templates for inputting relevant information accurately.

What is the purpose of SIMATIC PCS 7 Advanced ES?

The purpose of SIMATIC PCS 7 Advanced ES is to streamline the design, implementation, and management of control systems in industrial environments, enhancing efficiency, accuracy, and safety in automated processes.

What information must be reported on SIMATIC PCS 7 Advanced ES?

Information that must be reported on SIMATIC PCS 7 Advanced ES includes process data, control strategies, system configurations, safety measures, and any relevant operational parameters critical for effective monitoring and control.

Fill out your simatic pcs 7 advanced online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Simatic Pcs 7 Advanced is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.