Get the free CTS COPPER TUBING – GROOVED COUPLINGS

Show details

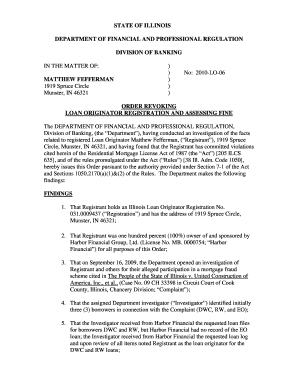

This document provides detailed information about the Victaulic copper connection system for joining large diameter copper tubing using grooved couplings. It includes specifications, installation

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign cts copper tubing grooved

Edit your cts copper tubing grooved form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your cts copper tubing grooved form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing cts copper tubing grooved online

To use our professional PDF editor, follow these steps:

1

Log into your account. In case you're new, it's time to start your free trial.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit cts copper tubing grooved. Add and replace text, insert new objects, rearrange pages, add watermarks and page numbers, and more. Click Done when you are finished editing and go to the Documents tab to merge, split, lock or unlock the file.

4

Save your file. Choose it from the list of records. Then, shift the pointer to the right toolbar and select one of the several exporting methods: save it in multiple formats, download it as a PDF, email it, or save it to the cloud.

pdfFiller makes working with documents easier than you could ever imagine. Register for an account and see for yourself!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out cts copper tubing grooved

How to fill out CTS COPPER TUBING – GROOVED COUPLINGS

01

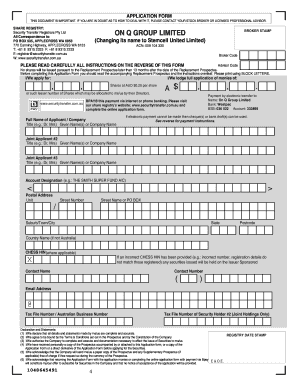

Gather all necessary materials, including CTS copper tubing, grooved couplings, fittings, and a pipe cutter.

02

Measure and cut the CTS copper tubing to the desired lengths using a pipe cutter.

03

Ensure that the ends of the copper tubing are clean and free of burrs. Use a deburring tool if necessary.

04

Select the appropriate size of grooved coupling for the tubing diameter.

05

Align the ends of the copper tubing with the grooved coupling.

06

Slide the grooved coupling over the ends of the tubing, ensuring they are fully inserted.

07

Secure the coupling in place by tightening any bolts or screws provided with the coupling.

08

Check for proper alignment and ensure there are no gaps.

09

Test the connection for leaks by running water through the system once installation is complete.

Who needs CTS COPPER TUBING – GROOVED COUPLINGS?

01

Plumbers and HVAC contractors working on residential or commercial plumbing systems.

02

Construction professionals involved in installing water supply and distribution systems.

03

Maintenance personnel responsible for repairing or upgrading existing piping systems.

04

Anyone involved in renovation projects that require new piping installations.

Fill

form

: Try Risk Free

People Also Ask about

What is a grooved coupling?

coupling. The pipe groove is made by forming or machining an actual groove into the ends of two pipes. A gasket wraps around and on top of the pipe ends, the housings wrap around the gasket and sit in the pipe grooves, and the bolts and nuts are tightened with a wrench to hold it all together.

What are the three types of couplings?

Types of Couplings Rigid coupling. Flexible coupling. Sleeve or coupling. Split coupling. Flange coupling. Gear coupling. Universal joint (Hooke's joint) Oldham coupling.

What is the purpose of a Victaulic coupling?

Victaulic couplings, or mechanical grooved couplings (also called mechanical pipe joining systems), are components that join mechanical pipes together to create a watertight joint.

What is the purpose of a groove joint?

Grooved joints are a versatile and efficient method of connecting pipes or shafts in a variety of applications, offering benefits such as faster installation, easier maintenance, and greater flexibility.

What are the different types of copper tubing connections?

Because of its high level of corrosion resistance, it is used for water distribution systems, oil fuel transfer lines, non-flammable medical-gas systems, and as a refrigerant line in HVAC systems. Copper tubing is joined using flare connection, compression connection, pressed connection, or solder.

How are grooved pipe couplings held together?

coupling. The pipe groove is made by forming or machining an actual groove into the ends of two pipes. A gasket wraps around and on top of the pipe ends, the housings wrap around the gasket and sit in the pipe grooves, and the bolts and nuts are tightened with a wrench to hold it all together.

What are grooved couplings?

Figure 774 Grooved Rigid Couplings are a proven dependable method of joining pipe and are an economical alternative to welding, threading, or using flanges. It is capable of pressures up to 34.5 Bar (500 psi) depending on pipe size and wall thickness when used in fire protection services.

What size copper tube is available when using the grooved method of joining?

This method of mechanical joining is also available in a system for copper tube in sizes from 2 through 8 inches. Included are couplings, gaskets and a myriad of fitting configurations. The system offers a practical alternative to soldering and brazing larger-diameter copper tube.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is CTS COPPER TUBING – GROOVED COUPLINGS?

CTS Copper Tubing – Grooved Couplings are specialized fittings used in plumbing and HVAC systems to connect sections of copper tubing. These couplings feature grooves that allow for quick and secure joining without the need for welding or soldering.

Who is required to file CTS COPPER TUBING – GROOVED COUPLINGS?

Typically, manufacturers, suppliers, and contractors involved in the installation or provision of CTS Copper Tubing – Grooved Couplings are required to file any necessary documentation or reports related to these products.

How to fill out CTS COPPER TUBING – GROOVED COUPLINGS?

Filling out CTS Copper Tubing – Grooved Couplings involves providing accurate product specifications, including size, material details, and application information. It may also require a declaration of compliance with relevant standards.

What is the purpose of CTS COPPER TUBING – GROOVED COUPLINGS?

The purpose of CTS Copper Tubing – Grooved Couplings is to facilitate the secure and efficient connection of copper tubing in various systems, ensuring leak-free joins and ease of maintenance in plumbing and HVAC applications.

What information must be reported on CTS COPPER TUBING – GROOVED COUPLINGS?

Information that must be reported includes the dimensions of the couplings, material specifications, compliance with industry standards, manufacturer details, and any applicable installation guidelines.

Fill out your cts copper tubing grooved online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Cts Copper Tubing Grooved is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.