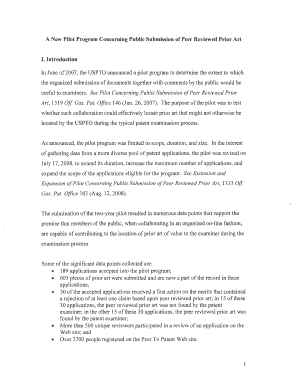

Get the free Engineering Perform basic welding thermal cutting

Show details

Unit of Competency: VBN782 engineering structures Learning Outcomes 1 Plan welding and thermal cutting Assessment Record Perform basic welding & thermal cutting processes to fabricate Performance

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign engineering perform basic welding

Edit your engineering perform basic welding form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your engineering perform basic welding form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing engineering perform basic welding online

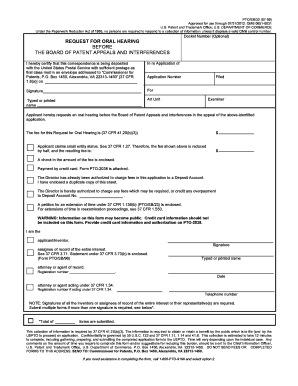

To use our professional PDF editor, follow these steps:

1

Set up an account. If you are a new user, click Start Free Trial and establish a profile.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit engineering perform basic welding. Rearrange and rotate pages, add new and changed texts, add new objects, and use other useful tools. When you're done, click Done. You can use the Documents tab to merge, split, lock, or unlock your files.

4

Save your file. Select it in the list of your records. Then, move the cursor to the right toolbar and choose one of the available exporting methods: save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud.

With pdfFiller, dealing with documents is always straightforward. Try it right now!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out engineering perform basic welding

How to fill out engineering perform basic welding:

01

First, gather all the necessary equipment and tools needed for welding. This includes a welding machine, welding helmet, gloves, and protective clothing.

02

Next, ensure that the area you will be welding in is well-ventilated and free from any flammable materials. Safety precautions are essential in welding, so make sure you have a fire extinguisher nearby.

03

Before starting the welding process, inspect the materials you will be working with and clean them thoroughly. Remove any grease, oil, or rust that may affect the quality of the weld.

04

Set up your welding machine according to the specifications of the materials and the type of welding you will be performing. Make sure to adjust the voltage, amperage, and wire feed speed accordingly.

05

Put on your welding helmet and gloves, ensuring that your eyes, face, and hands are fully protected from the intense heat and sparks generated during the welding process.

06

Position the materials you will be welding together in the desired configuration, using clamps or fixtures if necessary to hold them in place.

07

Start the welding process by striking an arc between the material and the welding electrode. Maintain a steady hand and travel speed to create a clean and consistent weld.

08

Continue welding along the desired joint, gradually moving along and applying filler metal if needed. Pay attention to the appearance of the weld and make any necessary adjustments to achieve the desired result.

09

Once you have completed the welding, allow the weld to cool down before inspecting it. Check for any defects such as cracks, porosity, or incomplete fusion. If any issues are found, rework the weld as necessary.

10

Finally, clean up the work area, properly store the welding equipment, and ensure everything is in a safe condition for future use.

Who needs engineering perform basic welding:

01

Engineering students who want to enhance their skillset and have a basic knowledge of welding techniques and processes can benefit from learning how to perform basic welding. It can be a valuable addition to their educational background and make them more marketable in the job market.

02

Professionals in the engineering field who work with metal structures, machinery, or manufacturing processes may require basic welding skills. Being able to perform basic welding can help them repair or modify equipment as needed, saving time and money in outsourcing welding work.

03

Hobbyists or DIY enthusiasts who engage in metalwork projects can greatly benefit from learning how to perform basic welding. Whether it's for building furniture, sculptures, or other creative projects, having welding skills can open up a world of possibilities and allow them to bring their ideas to life.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I sign the engineering perform basic welding electronically in Chrome?

Yes. You can use pdfFiller to sign documents and use all of the features of the PDF editor in one place if you add this solution to Chrome. In order to use the extension, you can draw or write an electronic signature. You can also upload a picture of your handwritten signature. There is no need to worry about how long it takes to sign your engineering perform basic welding.

Can I edit engineering perform basic welding on an iOS device?

Create, modify, and share engineering perform basic welding using the pdfFiller iOS app. Easy to install from the Apple Store. You may sign up for a free trial and then purchase a membership.

Can I edit engineering perform basic welding on an Android device?

You can. With the pdfFiller Android app, you can edit, sign, and distribute engineering perform basic welding from anywhere with an internet connection. Take use of the app's mobile capabilities.

What is engineering perform basic welding?

Engineering performing basic welding involves using welding techniques to join two metal pieces together.

Who is required to file engineering perform basic welding?

Engineers or welding professionals who are tasked with performing basic welding tasks.

How to fill out engineering perform basic welding?

To fill out engineering perform basic welding, one must document the welding process, materials used, and any inspections or tests conducted.

What is the purpose of engineering perform basic welding?

The purpose of engineering perform basic welding is to securely join metal pieces together to create a strong bond.

What information must be reported on engineering perform basic welding?

Information such as welding procedure, materials used, equipment utilized, and any quality control measures taken must be reported on engineering perform basic welding.

Fill out your engineering perform basic welding online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Engineering Perform Basic Welding is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.