Get the free Metal Seal Design Guide

Show details

The document serves as a comprehensive guide for understanding and selecting metal seals for various applications, emphasizing on design, materials, installation, and performance data.

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign metal seal design guide

Edit your metal seal design guide form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your metal seal design guide form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing metal seal design guide online

Use the instructions below to start using our professional PDF editor:

1

Check your account. If you don't have a profile yet, click Start Free Trial and sign up for one.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit metal seal design guide. Text may be added and replaced, new objects can be included, pages can be rearranged, watermarks and page numbers can be added, and so on. When you're done editing, click Done and then go to the Documents tab to combine, divide, lock, or unlock the file.

4

Save your file. Select it in the list of your records. Then, move the cursor to the right toolbar and choose one of the available exporting methods: save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud.

pdfFiller makes working with documents easier than you could ever imagine. Try it for yourself by creating an account!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

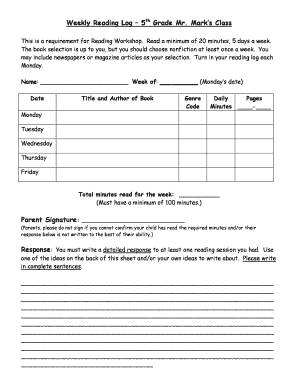

How to fill out metal seal design guide

How to fill out Metal Seal Design Guide

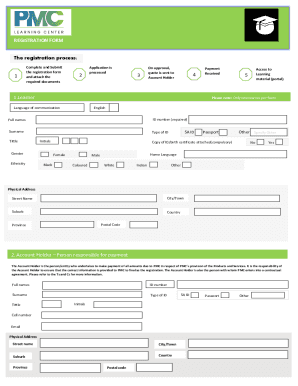

01

Gather all necessary design data and specifications for the metal seal.

02

Review the sections of the Metal Seal Design Guide to understand the required information.

03

Fill in the 'General Information' section with details about the application and environment.

04

Specify the seal type and material based on application requirements.

05

Input dimensions and tolerances, ensuring accuracy to prevent sealing issues.

06

Discuss pressure and temperature conditions that the seal will encounter.

07

Complete any additional sections relevant to special features or considerations for the design.

08

Review the guide to ensure all data is accurate and complete before submission.

Who needs Metal Seal Design Guide?

01

Engineers and designers involved in seal design for machinery and equipment.

02

Manufacturers of seals looking for standardized design guidelines.

03

Quality assurance teams ensuring compliance with design specifications.

04

Academics and students studying mechanical engineering or fluid dynamics.

Fill

form

: Try Risk Free

People Also Ask about

How to design a good seal?

There are 3 key considerations for designing a good seal: Cross sectional “squeeze” Gland fill. Material selection for seal and gland.

What is the difference between E seal and C seal?

Note that typically only O-Rings and C-Seals are plated because they generate enough assembly load to deform the plating. E-Seals are usually not plated because they do not generate enough assembly load to deform the plating.

How to design a mechanical seal?

Fundamentals of Mechanical Seal Design The seal design includes a rotating face, a stationary face, and an interface region where these faces meet. Material selection, such as using carbon graphite or silicon carbide, enhances durability, especially for abrasive fluids.

What is the surface finish for metal to metal seal?

Importance of surface finish for metal seal applications Most of the metal seal applications require surface finish of 32 u inch RA or better. Anything over 32 u in RA will not be bubble tight sealing (leakage rate of 1x10^4 cc/sec) which could be okay for certain applications.

What are the considerations for seal design?

Selecting the right material is the first and most critical step in designing a custom seal. Physical, resistance, and mechanical properties must all be taken into consideration for performance requirements, while material cost and processing must be considered to stay within budget.

How to design a family seal?

Designing a Family Crest Choose a shape for your coat of arms — shields are traditional, but any shape will work. Divide the shape into four sections with a symbol in each, or fill the space with one symbol. Choose symbols that represent your family's identity, values, or interests.

How to seal metal to metal?

If you are joining two pieces of metal, use hybrid products for bonding and sealing, not only a sealant. Apply a layer of about 5mm of the adhesive sealant for metal to one surface and push firmly together, using a spacer.

What makes a good seal?

Medium, temperature, pressure and time say a lot about the requirements the seal must meet. These factors also have a major influence on the performance and design of the rubber seals. Other aspects such as the shape, operating time and, for example, quality brands are also important.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is Metal Seal Design Guide?

The Metal Seal Design Guide is a comprehensive document that provides guidelines and standards for the design, selection, and application of metal seals in various engineering and manufacturing processes.

Who is required to file Metal Seal Design Guide?

Individuals or organizations involved in the manufacturing, distribution, or usage of metal seals in their products are required to file the Metal Seal Design Guide.

How to fill out Metal Seal Design Guide?

To fill out the Metal Seal Design Guide, you need to follow the specified format, providing all required technical information, including seal specifications, application conditions, and compliance with relevant standards.

What is the purpose of Metal Seal Design Guide?

The purpose of the Metal Seal Design Guide is to ensure that proper design practices are followed, enhancing performance, reliability, and safety in applications where metal seals are used.

What information must be reported on Metal Seal Design Guide?

Information that must be reported includes seal dimensions, material specifications, operating conditions, performance data, and any relevant testing or compliance results.

Fill out your metal seal design guide online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Metal Seal Design Guide is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.