Get the free Cold Galvanize Coating Zinc Rich 7007VG - US - Aervoe

Show details

Safety Data Sheet (SDS) Date Prepared×Revised: 10×2/2014 Version no.: 01 Supersedes: () 1.) Identification of the Mixture and of the Company Product identifier: Crown 7007VG Cold Galvanize Coating

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign cold galvanize coating zinc

Edit your cold galvanize coating zinc form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your cold galvanize coating zinc form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing cold galvanize coating zinc online

In order to make advantage of the professional PDF editor, follow these steps:

1

Register the account. Begin by clicking Start Free Trial and create a profile if you are a new user.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit cold galvanize coating zinc. Rearrange and rotate pages, add and edit text, and use additional tools. To save changes and return to your Dashboard, click Done. The Documents tab allows you to merge, divide, lock, or unlock files.

4

Get your file. When you find your file in the docs list, click on its name and choose how you want to save it. To get the PDF, you can save it, send an email with it, or move it to the cloud.

With pdfFiller, it's always easy to work with documents.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out cold galvanize coating zinc

How to fill out cold galvanize coating zinc:

01

Clean the surface: Before applying the cold galvanize coating zinc, it is important to clean the surface thoroughly. Remove any dirt, grease, rust, or old coatings using a wire brush or sandpaper.

02

Prepare the coating: Shake the can of cold galvanize coating zinc well to ensure the contents are properly mixed. If necessary, stir the coating with a stick or paint mixer to achieve a uniform consistency.

03

Apply the coating: Use a paintbrush or roller to apply a thin and even layer of cold galvanize coating zinc onto the surface. Ensure that the entire area is covered, including any nooks or crevices.

04

Allow drying time: Let the first coat of cold galvanize coating zinc dry for the recommended time mentioned on the product label. This typically ranges from a few hours to overnight, depending on the brand.

05

Apply additional coats: If desired or required, apply additional coats of cold galvanize coating zinc. Follow the same application process as mentioned above and allow each coat to dry before applying the next.

06

Final curing: After the last coat, let the cold galvanize coating zinc cure for the recommended time mentioned on the product label. This is essential to ensure proper adhesion and durability.

Who needs cold galvanize coating zinc:

01

Metal fabrication industry: Cold galvanize coating zinc is commonly used in the metal fabrication industry to protect surfaces from corrosion and rust. It provides a durable and long-lasting coating that extends the lifespan of metal structures, equipment, and machinery.

02

DIY enthusiasts and homeowners: Cold galvanize coating zinc can also be used by DIY enthusiasts and homeowners for various applications. It can be applied to metal gates, fences, railings, outdoor furniture, and other metal items exposed to moisture or harsh weather conditions.

03

Automotive and marine industry: The automotive and marine industry often relies on cold galvanize coating zinc to protect vehicles, trailers, boats, and other metal components from corrosion caused by road salt, water, and other environmental factors.

In conclusion, anyone looking to protect metal surfaces from corrosion and rust can benefit from using cold galvanize coating zinc. It is suitable for both professional and DIY use, making it a versatile and effective solution for various industries and applications.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

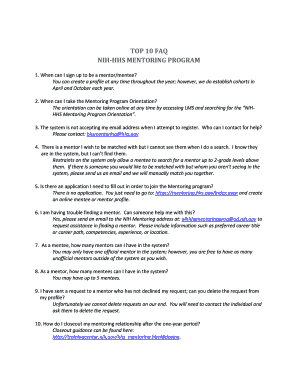

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Where do I find cold galvanize coating zinc?

The premium pdfFiller subscription gives you access to over 25M fillable templates that you can download, fill out, print, and sign. The library has state-specific cold galvanize coating zinc and other forms. Find the template you need and change it using powerful tools.

How do I execute cold galvanize coating zinc online?

Easy online cold galvanize coating zinc completion using pdfFiller. Also, it allows you to legally eSign your form and change original PDF material. Create a free account and manage documents online.

How can I fill out cold galvanize coating zinc on an iOS device?

Install the pdfFiller iOS app. Log in or create an account to access the solution's editing features. Open your cold galvanize coating zinc by uploading it from your device or online storage. After filling in all relevant fields and eSigning if required, you may save or distribute the document.

What is cold galvanize coating zinc?

Cold galvanize coating zinc is a method of applying a protective zinc coating to metal surfaces through a cold galvanizing process.

Who is required to file cold galvanize coating zinc?

Businesses or individuals that apply cold galvanize coating zinc to metal surfaces may be required to file reports on the process.

How to fill out cold galvanize coating zinc?

To fill out the cold galvanize coating zinc report, you must provide detailed information about the process, including the type of metal surface, the method of application, and any safety precautions taken.

What is the purpose of cold galvanize coating zinc?

The purpose of cold galvanize coating zinc is to provide a protective layer of zinc to metal surfaces, preventing corrosion and rust.

What information must be reported on cold galvanize coating zinc?

Information such as the type of metal surface, the zinc coating thickness, the date of application, and any safety measures taken must be reported on cold galvanize coating zinc.

Fill out your cold galvanize coating zinc online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Cold Galvanize Coating Zinc is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.