Get the free STEEL WELD

Show details

MASON INDUSTRIES, Inc. MERCER RUBBER Co. CRAVEN JOB NAME CUSTOMER 350 Ra bro Drive, Haulage, NY 11788 Mason 631×3480282 Info MasonInd.com Mercer 631×5821524 Info MercerRubber.com FAX 631×3480279

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign steel weld

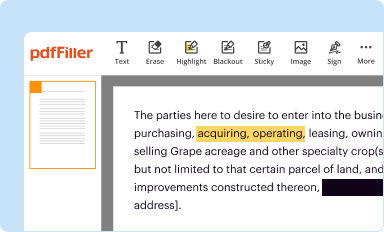

Edit your steel weld form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

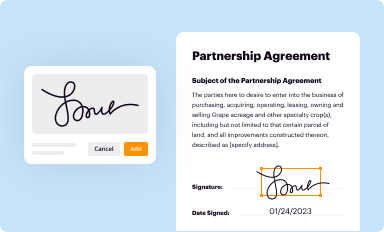

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your steel weld form via URL. You can also download, print, or export forms to your preferred cloud storage service.

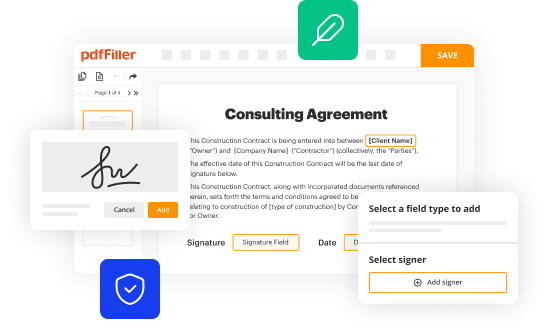

How to edit steel weld online

To use the professional PDF editor, follow these steps below:

1

Log in. Click Start Free Trial and create a profile if necessary.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit steel weld. Rearrange and rotate pages, add and edit text, and use additional tools. To save changes and return to your Dashboard, click Done. The Documents tab allows you to merge, divide, lock, or unlock files.

4

Save your file. Select it from your list of records. Then, move your cursor to the right toolbar and choose one of the exporting options. You can save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud, among other things.

With pdfFiller, it's always easy to work with documents. Try it!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out steel weld

How to fill out steel weld:

01

Clean the surface: Before filling out the steel weld, it is important to ensure that the surface is clean and free from any dirt, rust, or debris. Use a wire brush or sandpaper to remove any contaminants.

02

Prepare the weld area: Next, prepare the weld area by removing any edges or burrs that may interfere with the welding process. Use a grinder or a file to smooth out the edges and create a clean surface for the weld.

03

Choose the right welding method: There are various welding methods available for filling out steel weld, such as stick welding, MIG welding, and TIG welding. Select the method that is suitable for your project and ensure that you have the necessary equipment and safety gear.

04

Set up the welding equipment: Follow the manufacturer's instructions to set up your welding equipment properly. This may involve connecting the welding machine to a power source, installing the appropriate electrode or wire, and adjusting the settings for the specific type and thickness of steel you are working with.

05

Preheat the steel: Depending on the thickness and type of steel, preheating may be required to reduce the risk of cracking. Consult the welding specifications or guidelines to determine the appropriate preheating temperature.

06

Begin the welding process: Position the electrode or welding gun at a 10-15 degree angle to the workpiece and start the welding process. Move the electrode or welding gun in a controlled motion, applying the filler metal to the weld area. Ensure that the weld bead is of sufficient size and fully penetrates the joint.

07

Control the heat input: One of the key aspects of filling out a steel weld is controlling the heat input. Excessive heat can result in distortion or failure of the weld, while insufficient heat may lead to incomplete fusion. Practice proper heat control by adjusting the welding settings and maintaining a consistent travel speed.

08

Inspect and clean the weld: Once the weld is completed, inspect it for any defects or imperfections. Use a wire brush or grinder to remove any slag or spatter from the surface. A clean and smooth weld is essential for strong and durable joint.

Who needs steel weld?

01

Construction industry: Steel welds are crucial in the construction industry for joining and fabricating structural steel components. From buildings and bridges to pipelines and offshore platforms, steel welds are used to create strong and reliable structures.

02

Manufacturing industry: Various manufacturing processes require steel welds, including the production of machinery, automobiles, and appliances. Steel welds are used to assemble and join different components, ensuring proper functionality and durability.

03

Maintenance and repair work: Steel welds are also necessary for maintenance and repair work in different industries. Whether it is repairing a damaged steel structure or replacing a broken part, steel welds play a vital role in restoring functionality and extending the lifespan of various equipment and assets.

04

Metal fabrication: Metal fabricators use steel welds to create intricate and customized metal products. From decorative art pieces to industrial machinery, steel welds are essential for joining and manipulating metal pieces to achieve the desired shape and structure.

05

DIY enthusiasts: Even for individuals undertaking DIY projects at home or in their workshops, steel welds can be useful. From crafting metal furniture to building metal structures, knowing how to fill out steel weld can empower DIY enthusiasts to create their own projects with strength and precision.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit steel weld online?

pdfFiller not only allows you to edit the content of your files but fully rearrange them by changing the number and sequence of pages. Upload your steel weld to the editor and make any required adjustments in a couple of clicks. The editor enables you to blackout, type, and erase text in PDFs, add images, sticky notes and text boxes, and much more.

How do I make edits in steel weld without leaving Chrome?

Download and install the pdfFiller Google Chrome Extension to your browser to edit, fill out, and eSign your steel weld, which you can open in the editor with a single click from a Google search page. Fillable documents may be executed from any internet-connected device without leaving Chrome.

How do I edit steel weld on an iOS device?

Create, edit, and share steel weld from your iOS smartphone with the pdfFiller mobile app. Installing it from the Apple Store takes only a few seconds. You may take advantage of a free trial and select a subscription that meets your needs.

What is steel weld?

Steel weld is the process of joining two or more pieces of steel together by heating them to a high temperature and then allowing them to cool, creating a strong bond.

Who is required to file steel weld?

Steel weld must be filed by individuals or companies involved in welding steel as part of their business operations.

How to fill out steel weld?

Steel weld can be filled out by providing information about the type of steel being welded, the welding process used, and any other relevant details.

What is the purpose of steel weld?

The purpose of steel weld is to create a secure and durable bond between steel components, ensuring structural integrity and safety.

What information must be reported on steel weld?

Information such as the type of steel used, the welding technique employed, and any safety measures taken must be reported on steel weld.

Fill out your steel weld online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Steel Weld is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.