Get the free SECONDARY ALUMINUM SWEAT FURNACES - dep state fl

Show details

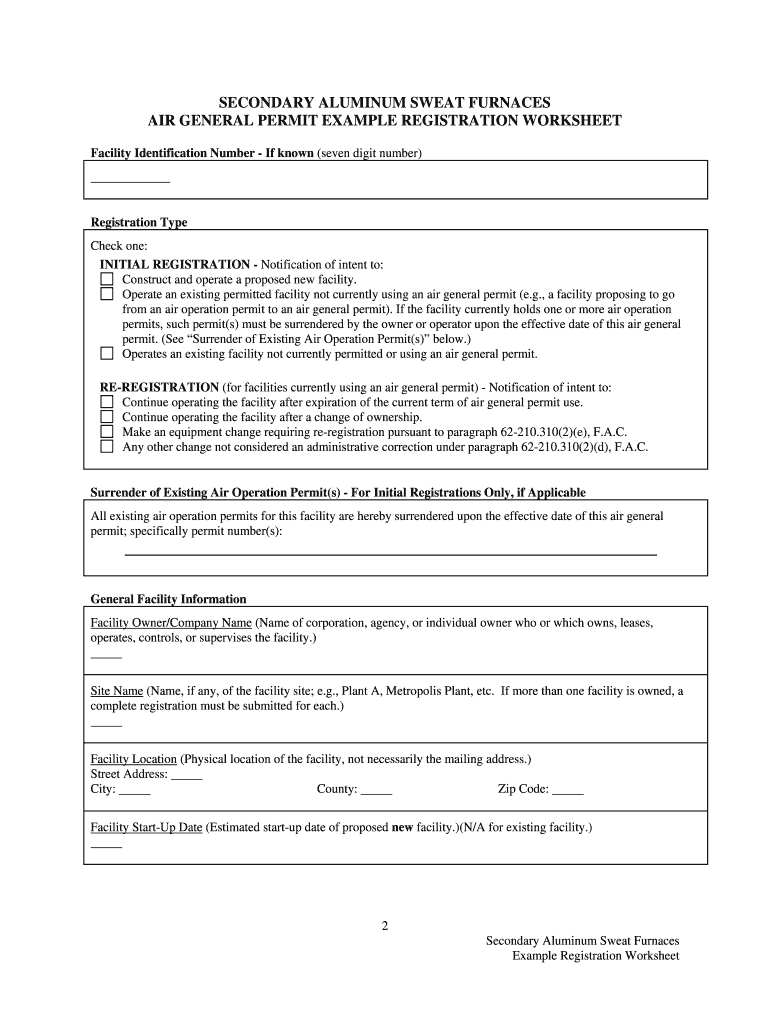

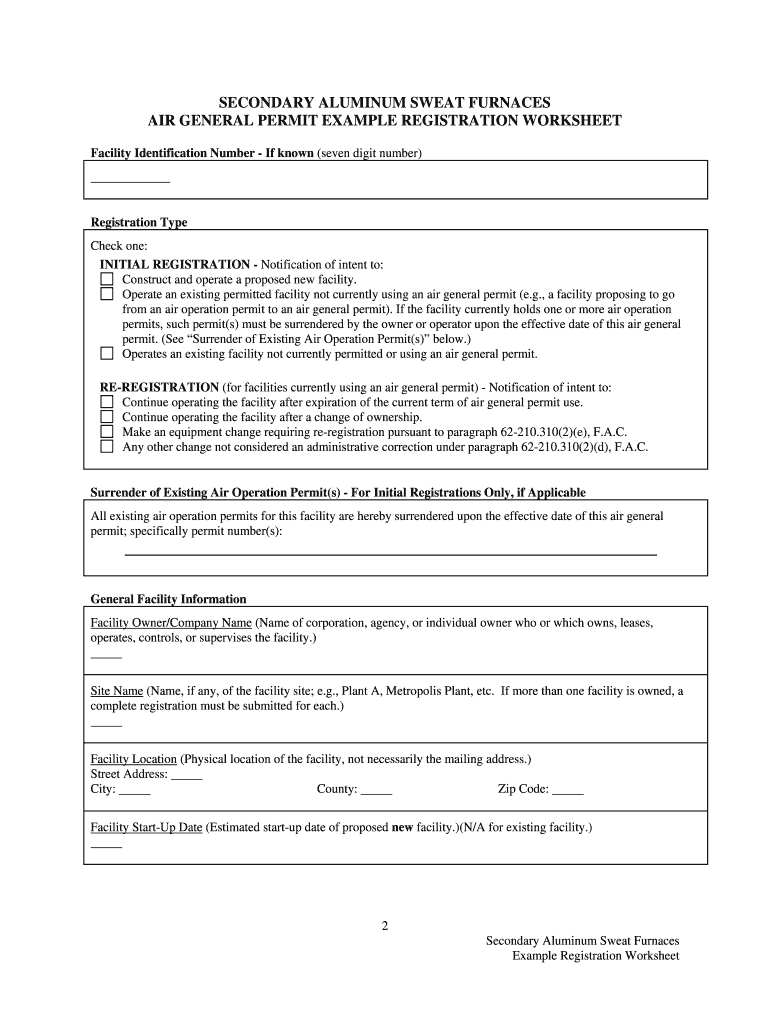

This document serves as a registration worksheet for facilities that wish to obtain an air general permit for secondary aluminum sweat furnaces as established by the Florida Department of Environmental

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign secondary aluminum sweat furnaces

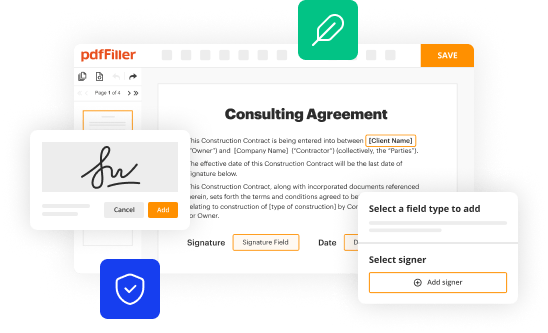

Edit your secondary aluminum sweat furnaces form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your secondary aluminum sweat furnaces form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing secondary aluminum sweat furnaces online

Here are the steps you need to follow to get started with our professional PDF editor:

1

Check your account. If you don't have a profile yet, click Start Free Trial and sign up for one.

2

Prepare a file. Use the Add New button to start a new project. Then, using your device, upload your file to the system by importing it from internal mail, the cloud, or adding its URL.

3

Edit secondary aluminum sweat furnaces. Add and replace text, insert new objects, rearrange pages, add watermarks and page numbers, and more. Click Done when you are finished editing and go to the Documents tab to merge, split, lock or unlock the file.

4

Save your file. Select it from your list of records. Then, move your cursor to the right toolbar and choose one of the exporting options. You can save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud, among other things.

pdfFiller makes dealing with documents a breeze. Create an account to find out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out secondary aluminum sweat furnaces

How to fill out SECONDARY ALUMINUM SWEAT FURNACES

01

Gather all necessary materials and equipment.

02

Ensure the furnace is clean and free from contaminants.

03

Preheat the furnace to the specified temperature.

04

Prepare the aluminum scrap for loading by removing any non-aluminum materials.

05

Load the aluminum scrap into the furnace slowly and evenly.

06

Monitor the temperature and adjust as needed to maintain optimal melting conditions.

07

Allow the aluminum to melt completely, stirring occasionally to ensure uniform melting.

08

Once melted, pour the aluminum into molds or transport it as needed for further processing.

Who needs SECONDARY ALUMINUM SWEAT FURNACES?

01

Metal recycling companies looking to process aluminum scrap.

02

Foundries that need to melt aluminum for casting.

03

Manufacturers of aluminum products requiring recycled materials.

04

Businesses involved in producing aluminum alloys.

Fill

form

: Try Risk Free

People Also Ask about

What is secondary production of aluminium?

Secondary Production is the process of recycling aluminum scrap into aluminum that can be used again — an environmentally sound process that is around 95% more energy efficient than primary production.

What is a sweat furnace?

A sweat furnace is a furnace that is used only to reclaim aluminum from scrap metal that contains aluminum and iron. Sweat furnaces reclaim aluminum by applying heat to the scrap to melt the aluminum but not so much heat that the iron melts.

What is the difference between primary and secondary smelting?

Lead processing and smelting plants work with both primary and secondary lead. Primary lead is mined, separated from ore, and refined into various products, whereas secondary lead is recovered from used objects, such as used lead-acid batteries, for reuse in other products.

What is the difference between primary and secondary aluminium ingots?

These primary aluminum ingots are created from raw bauxite ore, while secondary aluminum ingots are made from recycled scrap aluminum. They serve different purposes and have the benefits each type brings to the user based on cost, quality, and environmental considerations.

What is secondary smelting of aluminum?

The Secondary Aluminum Smelting Process Due to new sustainability drivers and environmental impacts, aluminum smelting in the scrap and secondary market is gaining popularity. This is the process of recycling aluminum scrap into aluminum that can be reused to form a green aluminum closed-loop process.

What is secondary smelting?

Secondary lead smelting - Secondary smelting produces lead and lead alloys from lead-bearing scrap metal. Raw materials used in secondary lead smelting include scrap automobile batteries, wheel balance weights, pipe, solder, drosses, and lead sheathing.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is SECONDARY ALUMINUM SWEAT FURNACES?

Secondary aluminum sweat furnaces are industrial systems used to melt and reclaim aluminum from scrap materials. They operate by applying heat to the aluminum scrap, which causes impurities to 'sweat' out, thus purifying the aluminum.

Who is required to file SECONDARY ALUMINUM SWEAT FURNACES?

Facilities that operate secondary aluminum sweat furnaces and are subject to environmental regulations, particularly regarding emissions and air quality, are required to file permits or reports related to their operations.

How to fill out SECONDARY ALUMINUM SWEAT FURNACES?

To fill out documentation for secondary aluminum sweat furnaces, operators must follow specific regional or federal guidelines, which typically include details about the furnace's operation, emissions data, and compliance with environmental standards.

What is the purpose of SECONDARY ALUMINUM SWEAT FURNACES?

The purpose of secondary aluminum sweat furnaces is to recycle aluminum scrap, reducing waste and conserving natural resources by allowing the recovery of aluminum for reuse in manufacturing.

What information must be reported on SECONDARY ALUMINUM SWEAT FURNACES?

Information that must be reported includes operational data, emissions measurements, types and amounts of scrap processed, and compliance with environmental regulations.

Fill out your secondary aluminum sweat furnaces online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Secondary Aluminum Sweat Furnaces is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.