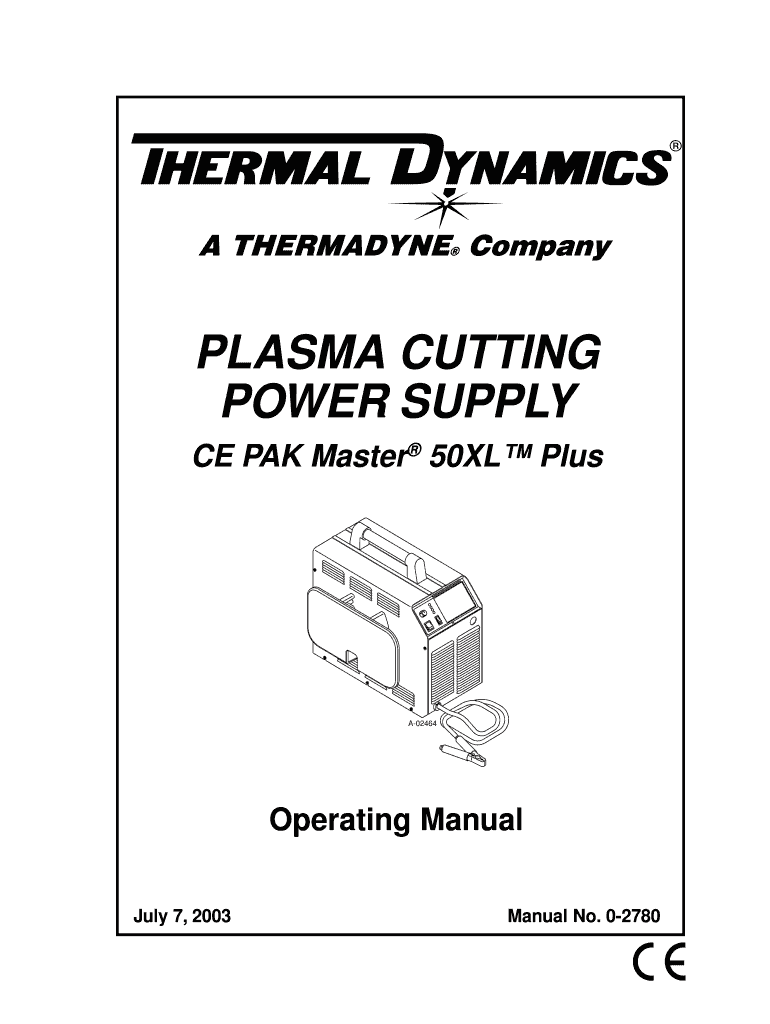

Get the free PLASMA CUTTING POWER SUPPLY CE PAK Master® 50XL™ Plus Operating Manual

Show details

This manual provides operating instructions, safety guidelines, and maintenance procedures for the CE PAK Master® 50XL™ Plus Plasma Cutting Power Supply.

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign plasma cutting power supply

Edit your plasma cutting power supply form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your plasma cutting power supply form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit plasma cutting power supply online

In order to make advantage of the professional PDF editor, follow these steps below:

1

Set up an account. If you are a new user, click Start Free Trial and establish a profile.

2

Simply add a document. Select Add New from your Dashboard and import a file into the system by uploading it from your device or importing it via the cloud, online, or internal mail. Then click Begin editing.

3

Edit plasma cutting power supply. Add and replace text, insert new objects, rearrange pages, add watermarks and page numbers, and more. Click Done when you are finished editing and go to the Documents tab to merge, split, lock or unlock the file.

4

Get your file. When you find your file in the docs list, click on its name and choose how you want to save it. To get the PDF, you can save it, send an email with it, or move it to the cloud.

pdfFiller makes working with documents easier than you could ever imagine. Create an account to find out for yourself how it works!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out plasma cutting power supply

How to fill out PLASMA CUTTING POWER SUPPLY CE PAK Master® 50XL™ Plus Operating Manual

01

Read the introduction section to understand the purpose and features of the PLASMA CUTTING POWER SUPPLY CE PAK Master® 50XL™ Plus.

02

Review the safety precautions to ensure safe operation while working with plasma cutting equipment.

03

Gather the necessary tools and materials outlined in the manual for proper setup and operation.

04

Follow the step-by-step installation instructions to set up the plasma cutting power supply correctly.

05

Refer to the electrical connection guidelines to ensure proper wiring and voltage specifications are met.

06

Check the adjustment settings for air pressure and amperage according to the specific cutting requirements.

07

Consult the troubleshooting section for common issues and their solutions to ensure smooth operation.

08

Review the maintenance section to understand how to properly care for and service the equipment over time.

Who needs PLASMA CUTTING POWER SUPPLY CE PAK Master® 50XL™ Plus Operating Manual?

01

Welders and metal fabricators who utilize plasma cutting technology in their projects.

02

Individuals or businesses that have purchased the PLASMA CUTTING POWER SUPPLY CE PAK Master® 50XL™ Plus.

03

Technical support personnel who assist in the setup and operation of plasma cutting machines.

04

Training instructors who educate others on the usage and benefits of plasma cutting equipment.

Fill

form

: Try Risk Free

People Also Ask about

What is the air pressure for thermal dynamics plasma cutter?

Most hand-held air plasma systems operate best around 70–80 PSI (4.8–5.5 bar). The exact value depends on the model, torch style, and material thickness. Always refer to your specific manual. For Thermal Dynamics Cutmaster systems, published True Cut™ ratings assume the correct pressure and flow at the torch.

What should air pressure be on a plasma cutter?

Cut50 Plasma Cutter Suggested Amperage & Air Setting Cutter Chart VoltageThickness (mm/inch)Air Pressure (psi) 220V 15mm (5/8 inch) 110V 110V 5mm (3/16 inch) 40-50 110V 6mm (1/4 inch) 40-50 110V 8mm (5/16 inch) 50-605 more rows • May 29, 2023

What is the code P1C on a Cutmaster 40?

The P1C code on a Cut Master 40 indicates a thermal overload or internal fault. First, ensure proper cooling by cleaning air vents and checking the fan operation. Inspect the power supply connections for tightness and corrosion. Overheating can trigger the thermal sensor, shutting down the unit to prevent damage.

What is the recommended air pressure for a titanium 45 plasma cutter?

Use a compressor that is capable of supplying 4.2 CFM @ 80-110 PSI.

How much air flow for a plasma cutter?

For a small handheld plasma cutter running at 20-30 amps, you'll need as little as 80 psi (5.5 bar). Larger, automated plasma cutting systems in the 130 to 800 amp range may require 115 psi (8 bar) or more.

What is the air pressure for a thermal dynamics plasma cutter?

Most hand-held air plasma systems operate best around 70–80 PSI (4.8–5.5 bar). The exact value depends on the model, torch style, and material thickness. Always refer to your specific manual. For Thermal Dynamics Cutmaster systems, published True Cut™ ratings assume the correct pressure and flow at the torch.

Which of the following is a common issue when plasma cutting?

Piercing too low One common error operators make is piercing too low. This causes molten metal to spatter onto the front of the nozzle and shield. Arc "snuffing" can even occur if the torch pierces when touching the metal, or drags along the surface while cutting.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is PLASMA CUTTING POWER SUPPLY CE PAK Master® 50XL™ Plus Operating Manual?

The PLASMA CUTTING POWER SUPPLY CE PAK Master® 50XL™ Plus Operating Manual is a comprehensive guide that provides instructions on the operation, maintenance, and troubleshooting of the plasma cutting power supply unit.

Who is required to file PLASMA CUTTING POWER SUPPLY CE PAK Master® 50XL™ Plus Operating Manual?

Users of the PLASMA CUTTING POWER SUPPLY CE PAK Master® 50XL™ Plus, including technicians and operators involved in plasma cutting processes, are required to reference and adhere to the guidelines in the operating manual.

How to fill out PLASMA CUTTING POWER SUPPLY CE PAK Master® 50XL™ Plus Operating Manual?

To fill out the PLASMA CUTTING POWER SUPPLY CE PAK Master® 50XL™ Plus Operating Manual, users should complete the relevant sections regarding operating procedures, safety measures, maintenance schedules, and any troubleshooting steps that apply to their specific usage.

What is the purpose of PLASMA CUTTING POWER SUPPLY CE PAK Master® 50XL™ Plus Operating Manual?

The purpose of the PLASMA CUTTING POWER SUPPLY CE PAK Master® 50XL™ Plus Operating Manual is to provide essential information and instructions to ensure safe and efficient operation of the plasma cutting equipment, as well as to outline proper maintenance practices.

What information must be reported on PLASMA CUTTING POWER SUPPLY CE PAK Master® 50XL™ Plus Operating Manual?

The information that must be reported in the PLASMA CUTTING POWER SUPPLY CE PAK Master® 50XL™ Plus Operating Manual includes safety warnings, technical specifications, operational procedures, maintenance instructions, and any compliance or regulatory information relevant to the equipment.

Fill out your plasma cutting power supply online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Plasma Cutting Power Supply is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.