Get the free Welded Tube and Pipe Market Tracker - Metal Bulletin Research

Show details

THE S IS This t is A On he is lat Prius is e y val subs st Ana sue a UAB crib lies ND LE an ERS is, f do end had ore s n up e a cast OT c to cues s or onto DAT s to the in e in of ta. for r m ma OST

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign welded tube and pipe

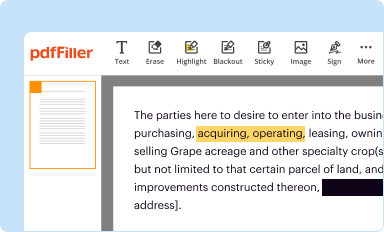

Edit your welded tube and pipe form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

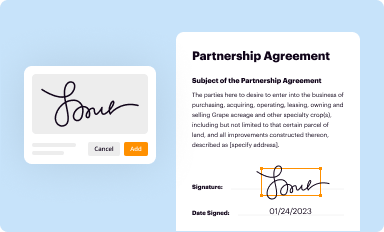

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

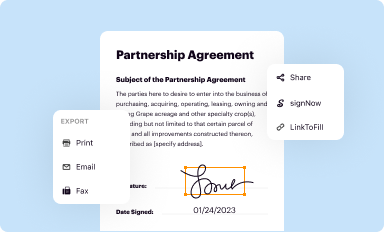

Share your form instantly

Email, fax, or share your welded tube and pipe form via URL. You can also download, print, or export forms to your preferred cloud storage service.

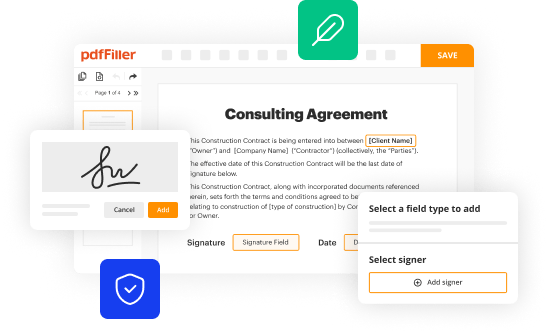

How to edit welded tube and pipe online

To use the services of a skilled PDF editor, follow these steps:

1

Log in to your account. Start Free Trial and register a profile if you don't have one yet.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit welded tube and pipe. Rearrange and rotate pages, insert new and alter existing texts, add new objects, and take advantage of other helpful tools. Click Done to apply changes and return to your Dashboard. Go to the Documents tab to access merging, splitting, locking, or unlocking functions.

4

Get your file. Select your file from the documents list and pick your export method. You may save it as a PDF, email it, or upload it to the cloud.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out welded tube and pipe

How to fill out welded tube and pipe?

01

Start by preparing the materials and tools needed for the job, such as the tube or pipe to be filled, welding equipment, protective gear, and any applicable filler material.

02

Before beginning the filling process, ensure that the tube or pipe is clean and free from any contaminants. Use a wire brush or grinder to remove any rust, scale, or debris from the surface.

03

Choose the appropriate filler material based on the type of tube or pipe and the application requirements. Common filler materials include welding rods, wires, or flux-cored wires.

04

Position the tube or pipe in the desired location, ensuring it is properly aligned and supported. Use clamps or fixtures if necessary to hold it in place.

05

Set up the welding equipment according to the manufacturer's instructions. Adjust the welding parameters, such as voltage, amperage, and wire feed speed, based on the thickness of the tube or pipe and the filler material being used.

06

Start the welding process by striking an arc at the desired starting point. Maintain a steady and controlled motion, ensuring that the filler material is evenly distributed along the weld joint.

07

Continue welding along the entire length of the tube or pipe, taking care to maintain a consistent heat input and proper penetration. Avoid excessive heat buildup or distortion by using proper techniques, such as intermittent welding or backstepping.

08

Once the welding is completed, inspect the weld joint for any defects or imperfections. Use visual inspection methods or non-destructive testing techniques, such as dye penetrant or radiographic inspection, to ensure the quality of the weld.

09

Clean and post-treat the welded tube or pipe as required. This may involve removing any welding slag, applying anti-corrosion coatings, or performing additional surface treatments.

Who needs welded tube and pipe?

01

Industries such as construction, manufacturing, and automotive rely on welded tube and pipe for various applications. These include structural support, fluid transportation, heat exchangers, and exhaust systems, among others.

02

Fabricators, welders, and metalworkers are among the professionals who often require welded tube and pipe to complete their projects. They use these materials to build or repair structures and components that require a high level of strength and durability.

03

Individuals or businesses involved in plumbing, HVAC (heating, ventilation, and air conditioning), or other types of piping systems also regularly use welded tube and pipe. These materials provide a reliable and efficient solution for transporting fluids, gases, or air in residential, commercial, or industrial settings.

In conclusion, filling out welded tube and pipe requires proper preparation, welding techniques, and post-treatment to ensure quality and reliability. Various industries and professionals, as well as individuals needing piping solutions, rely on welded tube and pipe for their specific applications.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I edit welded tube and pipe online?

With pdfFiller, you may not only alter the content but also rearrange the pages. Upload your welded tube and pipe and modify it with a few clicks. The editor lets you add photos, sticky notes, text boxes, and more to PDFs.

Can I create an eSignature for the welded tube and pipe in Gmail?

You may quickly make your eSignature using pdfFiller and then eSign your welded tube and pipe right from your mailbox using pdfFiller's Gmail add-on. Please keep in mind that in order to preserve your signatures and signed papers, you must first create an account.

How can I edit welded tube and pipe on a smartphone?

You can do so easily with pdfFiller’s applications for iOS and Android devices, which can be found at the Apple Store and Google Play Store, respectively. Alternatively, you can get the app on our web page: https://edit-pdf-ios-android.pdffiller.com/. Install the application, log in, and start editing welded tube and pipe right away.

What is welded tube and pipe?

Welded tube and pipe are metal products formed by joining pieces of metal through welding.

Who is required to file welded tube and pipe?

Manufacturers, distributors, and exporters of welded tube and pipe are required to file.

How to fill out welded tube and pipe?

Welded tube and pipe can be filled out electronically on the designated platform provided by the relevant governing body.

What is the purpose of welded tube and pipe?

The purpose of welded tube and pipe is to provide a means of transporting fluids or gases in various industries such as construction, automotive, and manufacturing.

What information must be reported on welded tube and pipe?

Information such as material composition, dimensions, weight, production country, and intended use must be reported on welded tube and pipe.

Fill out your welded tube and pipe online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Welded Tube And Pipe is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.