Get the free Mold-ready components unilifter core blades t-shaped

Show details

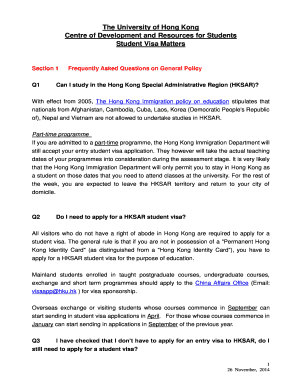

Mold ready components unilifter core blades: shaped A STANDARD TOLERANCES C1 W1 MW T1 W1 W2 Ref. An L C2 +.000 .001 +.000 .001 +.020 .000 +.020 .000 INCH +0 .025 +0 .025 +.5 .0 +.5 .0 METRIC Series

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign mold-ready components unilifter core

Edit your mold-ready components unilifter core form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your mold-ready components unilifter core form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit mold-ready components unilifter core online

In order to make advantage of the professional PDF editor, follow these steps:

1

Log in to your account. Click on Start Free Trial and register a profile if you don't have one.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit mold-ready components unilifter core. Rearrange and rotate pages, add and edit text, and use additional tools. To save changes and return to your Dashboard, click Done. The Documents tab allows you to merge, divide, lock, or unlock files.

4

Get your file. Select your file from the documents list and pick your export method. You may save it as a PDF, email it, or upload it to the cloud.

It's easier to work with documents with pdfFiller than you can have believed. You may try it out for yourself by signing up for an account.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out mold-ready components unilifter core

How to fill out mold-ready components unilifter core:

01

First, gather all the necessary components for the unilifter core. This may include the mold, lifting mechanism, and any additional accessories.

02

Carefully follow the instructions provided by the manufacturer to assemble the mold-ready components unilifter core. Make sure to connect each component securely and according to the designated guidelines.

03

Once the unilifter core is assembled, inspect it for any defects or irregularities. Ensure that all parts are aligned and functioning correctly before proceeding.

04

Next, prepare the mold by properly cleaning and lubricating it to ensure the smooth movement of the unilifter core. This step is crucial for preventing any damage to the mold or the unilifter core.

05

Carefully insert the mold-ready components unilifter core into the mold, ensuring that it is centered and properly aligned. Take caution not to force the unilifter core into the mold, as this could cause damage.

06

Double-check the fitment of the unilifter core within the mold, making any necessary adjustments if needed. It is crucial to ensure that the unilifter core moves smoothly and seamlessly within the mold.

07

Finally, secure the mold and unilifter core assembly according to the recommended guidelines. This may involve using clamps or other fastening methods to ensure stability during the molding process.

Who needs mold-ready components unilifter core?

01

Manufacturers or companies involved in injection molding processes often require mold-ready components unilifter core. This component helps in the efficient movement of molds and facilitates smoother production.

02

Mold designers and engineers who work on creating molds for various industries and applications rely on mold-ready components unilifter core to optimize their designs and ensure proper functionality.

03

Any individual or organization involved in custom mold making or mold production may require mold-ready components unilifter core to enhance the overall performance and precision of their molds.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I send mold-ready components unilifter core for eSignature?

When you're ready to share your mold-ready components unilifter core, you can send it to other people and get the eSigned document back just as quickly. Share your PDF by email, fax, text message, or USPS mail. You can also notarize your PDF on the web. You don't have to leave your account to do this.

How do I execute mold-ready components unilifter core online?

pdfFiller has made filling out and eSigning mold-ready components unilifter core easy. The solution is equipped with a set of features that enable you to edit and rearrange PDF content, add fillable fields, and eSign the document. Start a free trial to explore all the capabilities of pdfFiller, the ultimate document editing solution.

How do I edit mold-ready components unilifter core on an iOS device?

Yes, you can. With the pdfFiller mobile app, you can instantly edit, share, and sign mold-ready components unilifter core on your iOS device. Get it at the Apple Store and install it in seconds. The application is free, but you will have to create an account to purchase a subscription or activate a free trial.

What is mold-ready components unilifter core?

Mold-ready components unilifter core is a standardized component used in injection molding for lifting purposes.

Who is required to file mold-ready components unilifter core?

Manufacturers and suppliers who use mold-ready components unilifter core in their production processes are required to file.

How to fill out mold-ready components unilifter core?

To fill out mold-ready components unilifter core, you need to provide detailed information about the component, including specifications and usage instructions.

What is the purpose of mold-ready components unilifter core?

The purpose of mold-ready components unilifter core is to facilitate the lifting of molded parts during the production process.

What information must be reported on mold-ready components unilifter core?

Information such as component dimensions, material composition, weight capacity, and intended use must be reported on mold-ready components unilifter core.

Fill out your mold-ready components unilifter core online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Mold-Ready Components Unilifter Core is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.