Get the free Industrial Aluminum Electrolysis - tms

Show details

This document provides details about a definitive course on the theory and practice of primary aluminum production, including course topics, objectives, registration information, and presenter details.

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign industrial aluminum electrolysis

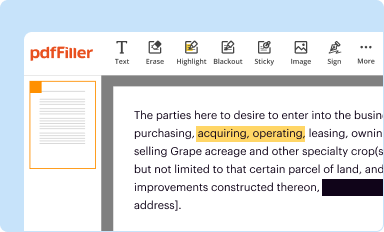

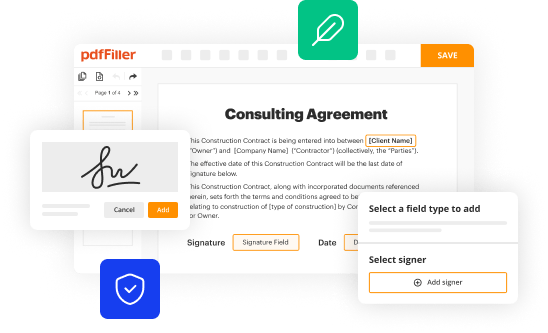

Edit your industrial aluminum electrolysis form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

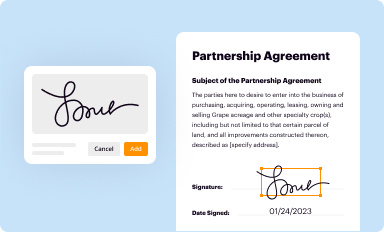

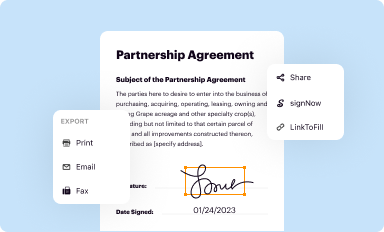

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your industrial aluminum electrolysis form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing industrial aluminum electrolysis online

Here are the steps you need to follow to get started with our professional PDF editor:

1

Log in. Click Start Free Trial and create a profile if necessary.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit industrial aluminum electrolysis. Add and change text, add new objects, move pages, add watermarks and page numbers, and more. Then click Done when you're done editing and go to the Documents tab to merge or split the file. If you want to lock or unlock the file, click the lock or unlock button.

4

Save your file. Choose it from the list of records. Then, shift the pointer to the right toolbar and select one of the several exporting methods: save it in multiple formats, download it as a PDF, email it, or save it to the cloud.

pdfFiller makes working with documents easier than you could ever imagine. Register for an account and see for yourself!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out industrial aluminum electrolysis

How to fill out Industrial Aluminum Electrolysis

01

Gather all necessary materials and equipment for the aluminum electrolysis process.

02

Prepare the electrolytic cell by cleaning and assembling it appropriately.

03

Fill the cell with the aluminum oxide (alumina) feedstock.

04

Add a suitable electrolyte, such as cryolite, to the electrolytic cell.

05

Connect the electrical power supply to the electrodes in the cell.

06

Set the power supply to the correct voltage and current levels required for electrolysis.

07

Monitor the temperature of the cell to ensure proper melting of the alumina and electrolyte.

08

Maintain the operating conditions and parameters throughout the electrolysis process.

09

Collect the aluminum once the electrolysis process is complete.

Who needs Industrial Aluminum Electrolysis?

01

Aluminum manufacturing companies looking to produce aluminum metal.

02

Industries requiring aluminum for various applications such as construction, automotive, and aerospace.

03

Research institutions studying metal extraction processes.

04

Companies focusing on recycling aluminum materials.

Fill

form

: Try Risk Free

People Also Ask about

What solvent is used in electrolysis of aluminium oxide?

Instead, it is dissolved. in molten. cryolite – an aluminium compound with a lower melting point than aluminium oxide. The use of molten cryolite as a solvent.

What is the process of electrolysis of aluminum?

Aluminum oxide is dissolved in molten cryolite, and the molten mixture is electrolyzed using carbon electrodes by passing a direct electric current through it producing pure aluminum metal. Therefore, it is called the Hall–Héroult process for manufacturing aluminum.

Why is electrolysis of aluminum expensive?

Extracting aluminium from its ore is expensive because its electrolysis requires a lot of energy.

How is aluminum produced using an electrolytic refining process?

The electrolytic process for aluminum production was discovered by Charles Hall in the USA and Paul Héroult in France independently in 1886. The Hall–Héroult process is based on electrolysis of alumina dissolved in molten cryolite.

What is the process of extraction of aluminum?

To extract aluminium, a process called electrolysis is employed, in which electrical current is used to reduce aluminium oxide to pure aluminium. Electrolysis: A chemical process that uses an electric current to drive a non-spontaneous reaction.

What is the process of aluminum electrolysis?

AlF63− and O2− are moved to the anode, where oxygen ions are discharged: 2O2− − 4e− → O2. Overall process of aluminum electrolysis is described by the following equation: (2)Al2O3 → 2Al + 1.5O2.

Does aluminium lose or gain electrons in electrolysis?

Aluminium electrolysis cell At the cathode, they gain electrons and are reduced to form aluminium metal. The negative oxide ions are attracted to the positive anode. At the anode, they lose electrons and are oxidised to form oxygen gas.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is Industrial Aluminum Electrolysis?

Industrial Aluminum Electrolysis is a process used to extract aluminum from its oxide, alumina, through an electrolytic method. This process involves passing an electric current through a molten mixture of alumina and other materials to separate aluminum from oxygen, resulting in the production of pure aluminum metal.

Who is required to file Industrial Aluminum Electrolysis?

Entities involved in the industrial production of aluminum through electrolysis are typically required to file Industrial Aluminum Electrolysis. This includes aluminum manufacturing plants and facilities that operate electrolytic reduction processes.

How to fill out Industrial Aluminum Electrolysis?

To fill out Industrial Aluminum Electrolysis, one must collect accurate data on the amount of alumina processed, the quantity of aluminum produced, energy consumption, and any emissions generated during the process. This information is then recorded and submitted on the required forms as specified by regulatory authorities.

What is the purpose of Industrial Aluminum Electrolysis?

The purpose of Industrial Aluminum Electrolysis is to efficiently and effectively produce aluminum metal from its ore while managing the environmental impacts associated with the production process. It aims to optimize yield and minimize energy consumption while adhering to regulatory standards.

What information must be reported on Industrial Aluminum Electrolysis?

Information that must be reported on Industrial Aluminum Electrolysis includes the total volume of alumina processed, the amount of aluminum produced, electricity usage, operational hours, and any relevant emissions data, along with compliance with environmental regulations.

Fill out your industrial aluminum electrolysis online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Industrial Aluminum Electrolysis is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.