Get the free WELDING bPROCEDURE SPECIFICATIONb - engstandards lanl

Show details

WELDING PROCEDURE SPECIFICATION WPS: REV. NO.: 0 CODE: ASHE IX 2010xxxx8F00 WELDING PROCESS: GTAWSUPPORTING PQR: DATE: 1/28/2015 **APPLICABILITY** OTHER: FCS4AR ASME01 JOINT: This WPS shall be used

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign welding bprocedure specificationb

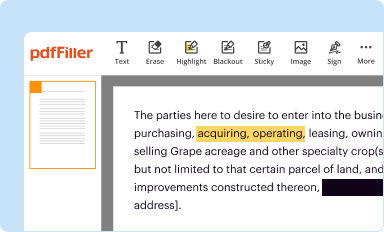

Edit your welding bprocedure specificationb form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

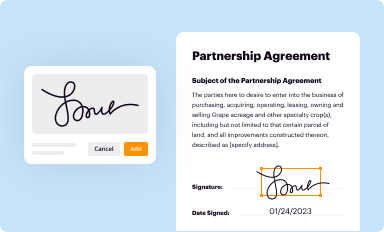

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

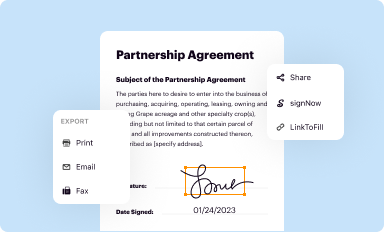

Share your form instantly

Email, fax, or share your welding bprocedure specificationb form via URL. You can also download, print, or export forms to your preferred cloud storage service.

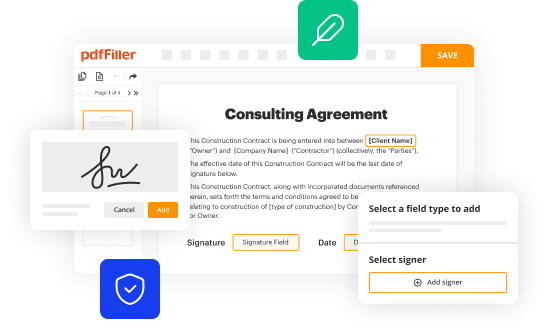

Editing welding bprocedure specificationb online

In order to make advantage of the professional PDF editor, follow these steps:

1

Log in. Click Start Free Trial and create a profile if necessary.

2

Simply add a document. Select Add New from your Dashboard and import a file into the system by uploading it from your device or importing it via the cloud, online, or internal mail. Then click Begin editing.

3

Edit welding bprocedure specificationb. Add and replace text, insert new objects, rearrange pages, add watermarks and page numbers, and more. Click Done when you are finished editing and go to the Documents tab to merge, split, lock or unlock the file.

4

Save your file. Select it in the list of your records. Then, move the cursor to the right toolbar and choose one of the available exporting methods: save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud.

With pdfFiller, it's always easy to deal with documents.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out welding bprocedure specificationb

How to fill out a welding procedure specification?

01

Start by gathering all necessary information: Before you begin filling out the welding procedure specification (WPS), make sure you have all the relevant details. This includes information about the base material, welding process, welding position, joint design, welding consumables, and any specific requirements or codes that need to be followed.

02

Identify the base material: The first step in filling out the WPS is to identify the base material being welded. This includes determining the material type (such as carbon steel, stainless steel, aluminum, etc.), its thickness, and any specific grades or specifications.

03

Determine the welding process: Decide on the welding process that will be used for the project. This can include processes like shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), etc. Consider factors such as the required weld quality, efficiency, and the specific welding equipment available.

04

Select the welding consumables: Choose the appropriate welding consumables, including electrodes or filler wires, gases, fluxes, and any other materials required for the welding process. Make sure the selected consumables are compatible with the base material and the chosen welding process.

05

Define the joint design: Determine the specific joint configuration and design that will be used for the welding project. This can include details such as joint type (butt joint, lap joint, etc.), groove angle, and beveling requirements.

06

Set the welding parameters: Specify the welding parameters that need to be followed during the welding process. This can include information about current, voltage, travel speed, preheat temperature, interpass temperature, and any post-weld heat treatment requirements.

07

Include any special instructions or requirements: If there are any special instructions or additional requirements for the welding project, such as specific weld inspections, testing, or any applicable codes or standards, make sure to include them in the WPS.

Who needs a welding procedure specification?

01

Welding fabricators: Welding procedure specifications are essential for welding fabricators who need to ensure that specific welding processes are followed to meet project requirements. These specifications help maintain consistency in weld quality and ensure that the necessary codes and standards are complied with.

02

Welding inspectors: Welding inspectors rely on welding procedure specifications to verify that welding activities are being carried out correctly and in compliance with industry standards. These specifications serve as a reference for inspections and help ensure the integrity and quality of welded joints.

03

Quality control personnel: Those responsible for quality control in welding operations use welding procedure specifications to monitor and document the adherence to prescribed welding processes. This helps maintain the desired weld quality and prevents deviations from approved procedures.

04

Welding engineers: Welding procedure specifications are an essential tool for welding engineers who are responsible for designing and implementing welding processes. These specifications serve as a guide for creating and validating welding procedures to ensure the desired weld quality and structural integrity.

05

Regulatory bodies: Regulatory bodies involved in ensuring product safety, such as government agencies or certification organizations, often require welding procedure specifications to verify that welding processes meet established standards. These specifications provide a means of evaluating compliance with industry regulations and codes.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is welding procedure specification?

A Welding Procedure Specification (WPS) is a document that provides guidance on the proper procedures and variables for a specific welding process.

Who is required to file welding procedure specification?

Welding procedure specifications are typically required to be filed by the welding engineer or the organization responsible for overseeing welding operations.

How to fill out welding procedure specification?

To fill out a welding procedure specification, one must detail the welding process, materials, techniques, and quality control measures to be used during welding.

What is the purpose of welding procedure specification?

The purpose of a welding procedure specification is to ensure consistency, quality, and safety in welding operations.

What information must be reported on welding procedure specification?

Information such as welding process details, material specifications, preheating requirements, welding parameters, and post-welding treatments must be reported on a welding procedure specification.

How do I fill out the welding bprocedure specificationb form on my smartphone?

You can easily create and fill out legal forms with the help of the pdfFiller mobile app. Complete and sign welding bprocedure specificationb and other documents on your mobile device using the application. Visit pdfFiller’s webpage to learn more about the functionalities of the PDF editor.

How do I edit welding bprocedure specificationb on an Android device?

You can. With the pdfFiller Android app, you can edit, sign, and distribute welding bprocedure specificationb from anywhere with an internet connection. Take use of the app's mobile capabilities.

How do I fill out welding bprocedure specificationb on an Android device?

Complete your welding bprocedure specificationb and other papers on your Android device by using the pdfFiller mobile app. The program includes all of the necessary document management tools, such as editing content, eSigning, annotating, sharing files, and so on. You will be able to view your papers at any time as long as you have an internet connection.

Fill out your welding bprocedure specificationb online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Welding Bprocedure Specificationb is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.