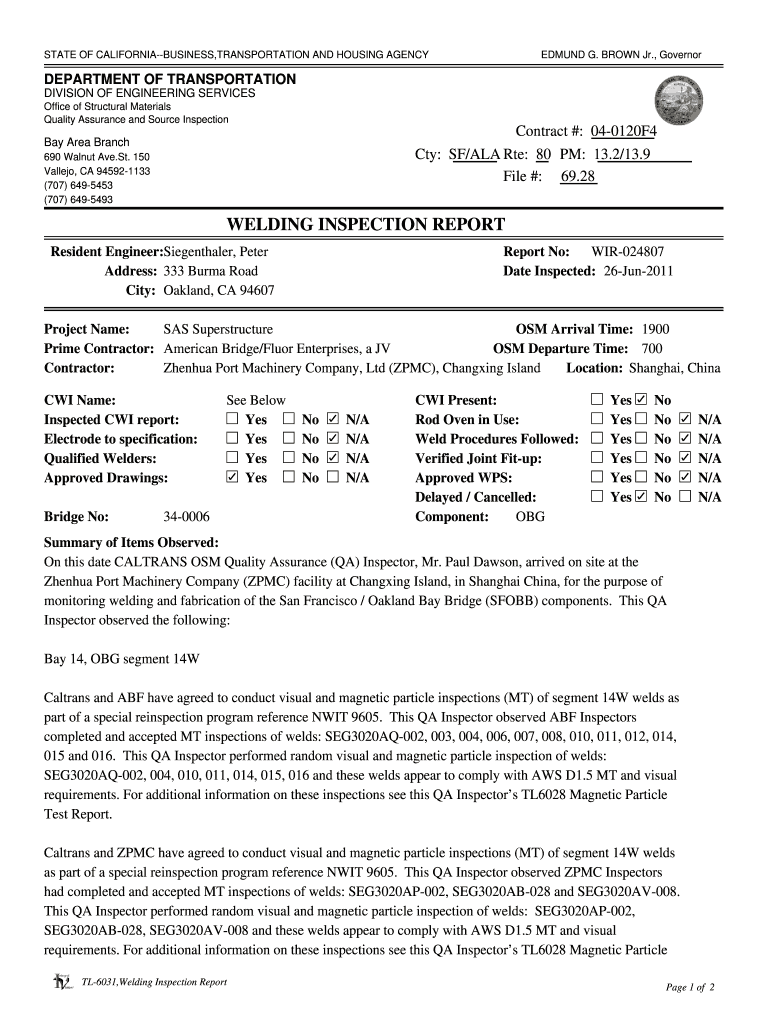

Get the free welding inspection report - Caltrans - California - dot ca

Show details

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign welding inspection report

Edit your welding inspection report form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your welding inspection report form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing welding inspection report online

Here are the steps you need to follow to get started with our professional PDF editor:

1

Register the account. Begin by clicking Start Free Trial and create a profile if you are a new user.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit welding inspection report. Text may be added and replaced, new objects can be included, pages can be rearranged, watermarks and page numbers can be added, and so on. When you're done editing, click Done and then go to the Documents tab to combine, divide, lock, or unlock the file.

4

Save your file. Select it from your list of records. Then, move your cursor to the right toolbar and choose one of the exporting options. You can save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud, among other things.

It's easier to work with documents with pdfFiller than you could have believed. Sign up for a free account to view.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out welding inspection report

How to fill out a welding inspection report:

01

Begin by documenting the basic information such as the project name, location, and the date of the inspection.

02

Clearly state the scope and purpose of the inspection, specifying the type of welding that was performed.

03

Provide details of the welding procedure, including the type of welding process used, the materials being welded, and any relevant welding standards or codes that apply.

04

Document the welding equipment used, such as the type of welding machine, electrode, or filler wire.

05

Record the welding parameters, such as the welding voltage, current, and travel speed.

06

Inspect and record the condition of the welding joints, checking for any visible defects such as cracks, porosity, or incomplete penetration.

07

Measure and record the dimensions of the welded joints, ensuring they meet the specified requirements.

08

Conduct any necessary non-destructive testing, such as visual inspection, radiographic testing, or ultrasonic testing, and record the results.

09

Provide a comprehensive summary of any defects or deviations from the welding specifications, as well as any corrective actions taken.

10

Finally, sign and date the inspection report, ensuring that it is complete and accurate.

Who needs a welding inspection report:

01

Welding contractors: They need a welding inspection report to demonstrate the quality and compliance of their welding work to clients and regulatory bodies.

02

Construction managers: They require welding inspection reports to assess the integrity and safety of welded structures and ensure compliance with project specifications.

03

Inspectors and certifying authorities: They rely on welding inspection reports to verify the quality and compliance of welding work and issue relevant certifications.

04

Engineering and design teams: They utilize welding inspection reports to evaluate the performance and reliability of welds in their designs and make any necessary improvements.

05

Maintenance personnel: They may reference welding inspection reports to understand the condition and potential issues with existing welds, allowing them to perform necessary repairs or replacements.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I make changes in welding inspection report?

With pdfFiller, the editing process is straightforward. Open your welding inspection report in the editor, which is highly intuitive and easy to use. There, you’ll be able to blackout, redact, type, and erase text, add images, draw arrows and lines, place sticky notes and text boxes, and much more.

Can I edit welding inspection report on an iOS device?

Yes, you can. With the pdfFiller mobile app, you can instantly edit, share, and sign welding inspection report on your iOS device. Get it at the Apple Store and install it in seconds. The application is free, but you will have to create an account to purchase a subscription or activate a free trial.

How do I edit welding inspection report on an Android device?

Yes, you can. With the pdfFiller mobile app for Android, you can edit, sign, and share welding inspection report on your mobile device from any location; only an internet connection is needed. Get the app and start to streamline your document workflow from anywhere.

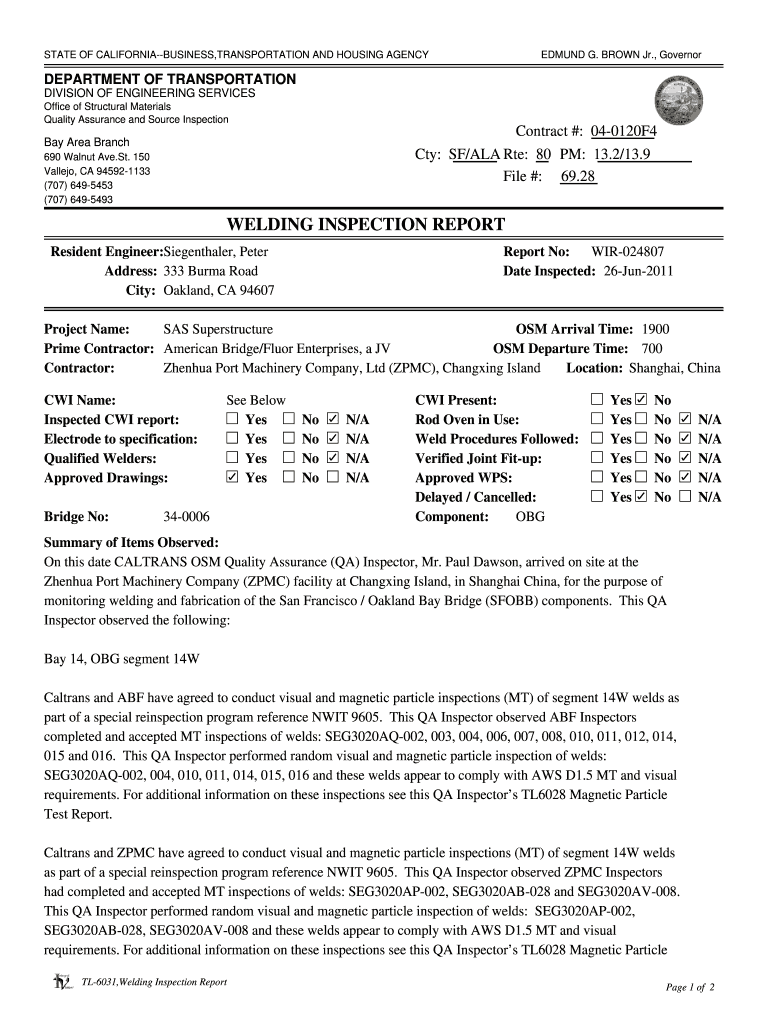

What is welding inspection report?

A welding inspection report is a document that records the results of inspections carried out on welds to ensure they meet industry standards and regulations.

Who is required to file welding inspection report?

Welding inspectors or welding supervisors are typically required to file welding inspection reports.

How to fill out welding inspection report?

To fill out a welding inspection report, inspectors must document details such as weld location, welder information, inspection results, and any required actions.

What is the purpose of welding inspection report?

The purpose of a welding inspection report is to ensure the quality and safety of welds in various structures or equipment.

What information must be reported on welding inspection report?

Information such as weld location, inspection date, inspector's name, inspection results, and any necessary follow-up actions must be reported on a welding inspection report.

Fill out your welding inspection report online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Welding Inspection Report is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.