Get the free Process Modeling for Metal Forming

Show details

Process Modeling for Metal Forming Die Stress Analysis Industry leaders have known for years that traditional methods of designing and troubleshooting tools and dies are not competitive. The cost

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign process modeling for metal

Edit your process modeling for metal form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your process modeling for metal form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit process modeling for metal online

To use our professional PDF editor, follow these steps:

1

Log in to your account. Start Free Trial and sign up a profile if you don't have one.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit process modeling for metal. Replace text, adding objects, rearranging pages, and more. Then select the Documents tab to combine, divide, lock or unlock the file.

4

Save your file. Choose it from the list of records. Then, shift the pointer to the right toolbar and select one of the several exporting methods: save it in multiple formats, download it as a PDF, email it, or save it to the cloud.

pdfFiller makes working with documents easier than you could ever imagine. Create an account to find out for yourself how it works!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out process modeling for metal

How to fill out process modeling for metal:

01

Identify the specific metal you are working with and gather information on its properties and characteristics. This will help in accurately representing the behavior of the metal during the modeling process.

02

Determine the desired outcome or objective of the process modeling. Are you trying to optimize a manufacturing process, improve efficiency, or simulate the performance of a metal component?

03

Define the inputs and variables that will be used in the modeling. This may include parameters such as temperature, pressure, alloy composition, and mechanical properties of the metal.

04

Select an appropriate process modeling software or tool that is capable of handling metal-specific simulations. There are various software options available that specialize in metal processing, such as finite element analysis (FEA) software or computational fluid dynamics (CFD) software.

05

Input the relevant data and parameters into the chosen software. This may involve creating a 3D model of the metal component or setting up the simulation environment for the process.

06

Run the simulation or modeling process based on the defined inputs. This will generate results and insights related to the behavior of the metal during the process being modeled.

07

Analyze the results and evaluate their significance. This step involves interpreting the data and making conclusions regarding the performance, efficiency, or improvements that can be made based on the modeling.

08

Implement any necessary changes or optimizations based on the insights gained from the process modeling. This may involve adjusting parameters, modifying manufacturing processes, or refining product designs.

09

Continuously validate and verify the accuracy of the process modeling by comparing the simulation results with real-world experiments or observations. This helps ensure the reliability and effectiveness of the modeling approach.

Who needs process modeling for metal?

01

Manufacturers and engineers involved in metal processing industries, such as automotive, aerospace, construction, and manufacturing sectors. Process modeling helps them optimize manufacturing processes, reduce costs, and improve product performance.

02

Researchers and scientists working on developing new metal alloys or materials. Process modeling enables them to simulate and predict the behavior of novel materials, aiding in the design and development process.

03

Quality control professionals who need to ensure consistent and reliable production of metal components. Process modeling allows them to identify and address potential issues or variations in the manufacturing process that may affect product quality.

04

Educational institutions and academic researchers who study the behavior and properties of metals. Process modeling serves as a valuable tool for teaching and research purposes, enhancing the understanding of metal processing and its applications.

05

Maintenance and repair technicians who work with metal components or structures. Process modeling helps them analyze and predict the performance of metal parts, aiding in the maintenance and predictive maintenance practices.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I edit process modeling for metal from Google Drive?

You can quickly improve your document management and form preparation by integrating pdfFiller with Google Docs so that you can create, edit and sign documents directly from your Google Drive. The add-on enables you to transform your process modeling for metal into a dynamic fillable form that you can manage and eSign from any internet-connected device.

Can I edit process modeling for metal on an Android device?

You can edit, sign, and distribute process modeling for metal on your mobile device from anywhere using the pdfFiller mobile app for Android; all you need is an internet connection. Download the app and begin streamlining your document workflow from anywhere.

How do I fill out process modeling for metal on an Android device?

Use the pdfFiller Android app to finish your process modeling for metal and other documents on your Android phone. The app has all the features you need to manage your documents, like editing content, eSigning, annotating, sharing files, and more. At any time, as long as there is an internet connection.

What is process modeling for metal?

Process modeling for metal is a method of representing the various steps and interactions involved in the production of metal products.

Who is required to file process modeling for metal?

Manufacturers and suppliers in the metal industry are required to file process modeling for metal.

How to fill out process modeling for metal?

Process modeling for metal can be filled out by documenting each stage of the metal production process and any relevant data.

What is the purpose of process modeling for metal?

The purpose of process modeling for metal is to ensure that the metal production process is efficient, safe, and environmentally friendly.

What information must be reported on process modeling for metal?

Information such as input materials, energy use, emissions, waste generation, and process efficiency must be reported on process modeling for metal.

Fill out your process modeling for metal online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Process Modeling For Metal is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

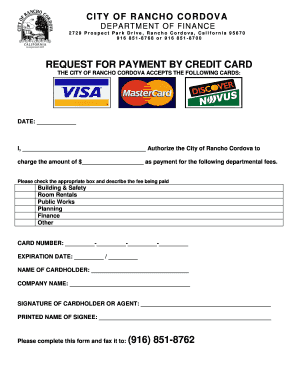

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.