Get the free Composite Cutting End Mills - Square - 2 Straight ... - Harvey Tool

Show details

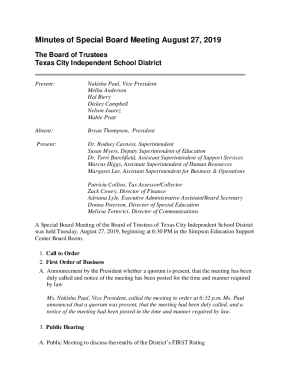

REQUEST FOR QUOTATION 2 FLUTE PLASTIC CUTTING END MILL (ABRASIVE) To help us serve you better, please fill in the information completely and either email it to tech harveytool.com or fax it to 978-948-8560.

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign composite cutting end mills

Edit your composite cutting end mills form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your composite cutting end mills form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit composite cutting end mills online

Here are the steps you need to follow to get started with our professional PDF editor:

1

Log in. Click Start Free Trial and create a profile if necessary.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit composite cutting end mills. Add and replace text, insert new objects, rearrange pages, add watermarks and page numbers, and more. Click Done when you are finished editing and go to the Documents tab to merge, split, lock or unlock the file.

4

Get your file. Select your file from the documents list and pick your export method. You may save it as a PDF, email it, or upload it to the cloud.

Dealing with documents is always simple with pdfFiller. Try it right now

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out composite cutting end mills

How to fill out composite cutting end mills:

01

Start by selecting the appropriate size and type of composite cutting end mill for the desired application. Consider factors such as the material being cut and the desired cutting speed.

02

Carefully inspect the end mill for any damage or wear before use. Check for any chips, cracks, or dullness in the cutting edges. Replace any damaged or worn-out end mills.

03

Secure the composite cutting end mill in a suitable tool holder or collet, ensuring a tight and secure fit. Follow the manufacturer's instructions for proper installation.

04

Adjust the cutting parameters on your milling machine or CNC router to match the requirements of the composite material being cut. This may include adjusting the spindle speed, feed rate, and depth of cut.

05

Position the composite material to be cut securely on the milling machine or CNC router table. Use clamps or other appropriate methods to prevent movement during the cutting process.

06

Start the milling machine or CNC router and carefully guide the composite cutting end mill into the material, following the desired cutting path. Take care to maintain a steady feed rate and avoid excessive tool engagement to prevent damage to the end mill and workpiece.

07

Continuously monitor the cutting process and adjust the cutting parameters as needed to achieve the desired results. Pay attention to signs of tool wear, such as decreased cutting performance or a rougher finish, and replace the end mill if necessary.

08

Once the cutting process is complete, carefully remove the composite cutting end mill from the tool holder or collet. Clean any chips or debris from the end mill and inspect it for any damage or wear.

09

Properly store the composite cutting end mill in a clean and dry environment to protect it from damage and extend its lifespan.

Who needs composite cutting end mills?

01

Machinists and manufacturers working with composite materials, such as carbon fiber, fiberglass, or laminates, often require composite cutting end mills. These materials can be challenging to machine due to their unique properties, and specialized tools like composite cutting end mills are designed to effectively cut through them.

02

Industries that commonly use composite materials, such as aerospace, automotive, marine, and sporting goods, may require composite cutting end mills for various applications. These include cutting composite panels, trimming edges, or creating intricate shapes and features in composite components.

03

DIY enthusiasts or hobbyists working with composite materials, such as in model-making or custom fabrication, may also benefit from using composite cutting end mills. These tools can help achieve precise and clean cuts in composite materials, enhancing the overall quality and finish of the project.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Can I create an eSignature for the composite cutting end mills in Gmail?

You may quickly make your eSignature using pdfFiller and then eSign your composite cutting end mills right from your mailbox using pdfFiller's Gmail add-on. Please keep in mind that in order to preserve your signatures and signed papers, you must first create an account.

How can I edit composite cutting end mills on a smartphone?

The pdfFiller apps for iOS and Android smartphones are available in the Apple Store and Google Play Store. You may also get the program at https://edit-pdf-ios-android.pdffiller.com/. Open the web app, sign in, and start editing composite cutting end mills.

How do I edit composite cutting end mills on an iOS device?

You certainly can. You can quickly edit, distribute, and sign composite cutting end mills on your iOS device with the pdfFiller mobile app. Purchase it from the Apple Store and install it in seconds. The program is free, but in order to purchase a subscription or activate a free trial, you must first establish an account.

What is composite cutting end mills?

Composite cutting end mills are used in machining operations to remove material from a workpiece using multiple cutting edges.

Who is required to file composite cutting end mills?

Manufacturers, distributors, and sellers of composite cutting end mills may be required to file reports.

How to fill out composite cutting end mills?

To fill out composite cutting end mills, one must provide detailed information about the product, including material composition, dimensions, and intended use.

What is the purpose of composite cutting end mills?

The purpose of composite cutting end mills is to efficiently cut and shape various materials, such as metal, wood, or plastic.

What information must be reported on composite cutting end mills?

Information such as product name, manufacturer details, material composition, dimensions, and intended use must be reported on composite cutting end mills.

Fill out your composite cutting end mills online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Composite Cutting End Mills is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.