What is PROCESS INATION: Foundry, Smelting & Die Cast Operations INSTRUCTIONS Form?

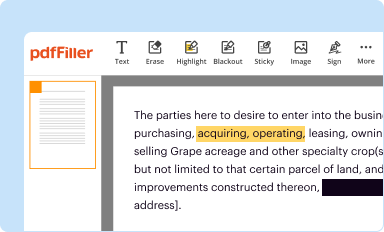

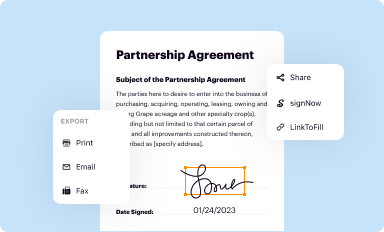

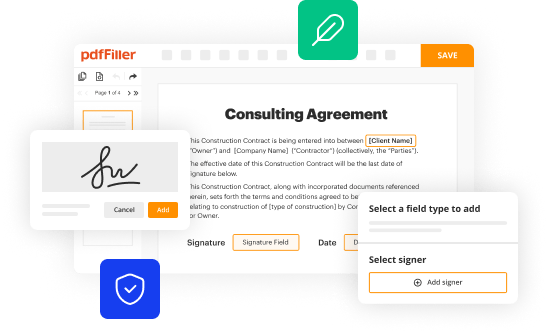

The PROCESS INATION: Foundry, Smelting & Die Cast Operations INSTRUCTIONS is a writable document that can be completed and signed for certain reasons. In that case, it is provided to the relevant addressee in order to provide certain details of any kinds. The completion and signing is possible in hard copy or via an appropriate tool e. g. PDFfiller. Such services help to complete any PDF or Word file online. It also allows you to edit it for your requirements and put a valid digital signature. Upon finishing, the user ought to send the PROCESS INATION: Foundry, Smelting & Die Cast Operations INSTRUCTIONS to the recipient or several recipients by mail and even fax. PDFfiller has a feature and options that make your document of MS Word extension printable. It provides various settings when printing out. It doesn't matter how you will file a form after filling it out - physically or electronically - it will always look neat and clear. In order not to create a new writable document from scratch all the time, make the original form into a template. After that, you will have an editable sample.

Template PROCESS INATION: Foundry, Smelting & Die Cast Operations INSTRUCTIONS instructions

When you're ready to start completing the PROCESS INATION: Foundry, Smelting & Die Cast Operations INSTRUCTIONS writable form, you have to make clear all the required details are well prepared. This one is important, due to errors and simple typos can lead to unwanted consequences. It's actually uncomfortable and time-consuming to resubmit forcedly the whole word template, not to mention penalties came from missed deadlines. Working with figures requires more attention. At first sight, there’s nothing tricky about it. Nonetheless, there's no anything challenging to make an error. Professionals recommend to record all required info and get it separately in a document. When you have a sample so far, you can easily export it from the file. In any case, it's up to you how far can you go to provide true and solid info. Check the information in your PROCESS INATION: Foundry, Smelting & Die Cast Operations INSTRUCTIONS form twice when filling all required fields. In case of any mistake, it can be promptly corrected with PDFfiller editor, so all deadlines are met.

Frequently asked questions about the form PROCESS INATION: Foundry, Smelting & Die Cast Operations INSTRUCTIONS

1. Can I submit confidential documents on the web safely?

Solutions dealing with such an information (even intel one) like PDFfiller do care about you to be satisfied with how secure your forms are. We offer you::

- Cloud storage where all data is kept protected with encryption. The user is the only person who has to access their personal documents. Disclosure of the information by the service is strictly prohibited.

- To prevent identity stealing, every file receives its unique ID number once signed.

- If you think that is not safe enough for you, choose additional security features you prefer then. They can set authorization for recipients, for example, request a photo or password. PDFfiller also provides specific folders where you can put your PROCESS INATION: Foundry, Smelting & Die Cast Operations INSTRUCTIONS fillable template and secure them with a password.

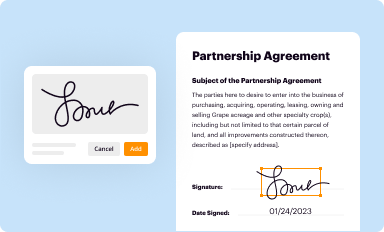

2. Have never heard about electronic signatures. Are they same comparing to physical ones?

Yes, it is absolutely legal. After ESIGN Act released in 2000, an electronic signature is considered as a legal tool. You are able to complete a file and sign it, and to official businesses it will be the same as if you signed a hard copy with pen, old-fashioned. While submitting PROCESS INATION: Foundry, Smelting & Die Cast Operations INSTRUCTIONS form, you have a right to approve it with a digital solution. Be sure that it matches to all legal requirements as PDFfiller does.

3. I have a sheet with some of required information all set. Can I use it with this form somehow?

In PDFfiller, there is a feature called Fill in Bulk. It helps to make an export of data from document to the online word template. The key advantage of this feature is that you can use it with Excel spread sheets.