Get the free Shielded Metal Arc Welding SMAWpub

Show details

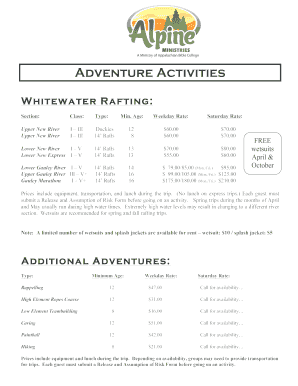

FMM Institute Center for Professional Development Inn- House Training Available SHIELDED METAL ARC WELDING (SAW) 1G/3G/6G This course is designed to offer necessary theoretical and practical exposure

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign shielded metal arc welding

Edit your shielded metal arc welding form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your shielded metal arc welding form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing shielded metal arc welding online

Use the instructions below to start using our professional PDF editor:

1

Log in. Click Start Free Trial and create a profile if necessary.

2

Simply add a document. Select Add New from your Dashboard and import a file into the system by uploading it from your device or importing it via the cloud, online, or internal mail. Then click Begin editing.

3

Edit shielded metal arc welding. Text may be added and replaced, new objects can be included, pages can be rearranged, watermarks and page numbers can be added, and so on. When you're done editing, click Done and then go to the Documents tab to combine, divide, lock, or unlock the file.

4

Get your file. Select the name of your file in the docs list and choose your preferred exporting method. You can download it as a PDF, save it in another format, send it by email, or transfer it to the cloud.

With pdfFiller, dealing with documents is always straightforward.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out shielded metal arc welding

How to fill out shielded metal arc welding:

01

Start by preparing the workpiece: Clean the surface to remove any dirt, rust, or paint. Ensure that the metal is free from contaminants as they can affect the quality of the weld.

02

Choose the appropriate electrode: Consider the type of metal being welded and the desired outcome. Select an electrode that is compatible with the base metal and provides the desired strength and characteristics.

03

Set up the welding machine: Adjust the voltage, amperage, and polarity according to the manufacturer's recommendations for the electrode being used. Ensure a stable power supply and proper grounding.

04

Insert the electrode into the welding machine: Make sure the electrode is securely fastened and properly positioned. Expose an appropriate length of the electrode, considering the welding position and joint configuration.

05

Prepare for welding: Put on appropriate personal protective equipment, including welding gloves, helmet, and clothing. Ensure proper ventilation in the work area to prevent the accumulation of toxic fumes.

06

Strike an arc: Touch the electrode to the workpiece and quickly withdraw it to create an arc. Maintain a suitable arc length, usually around 1/8 inch, to ensure stability and avoid excessive spatter.

07

Control the welding technique: Move the electrode in a controlled manner along the joint, maintaining the desired welding speed and angle. Ensure adequate penetration and fusion between the base metal and the electrode.

08

Monitor the welding process: Observe the appearance of the arc, the weld pool, and the weld bead. Ensure proper heat input, avoiding excessive or insufficient penetration. Make adjustments as necessary.

09

Fill the joint: Apply the electrode to the joint, adding filler metal as needed to create a sound and complete weld. Control the size and shape of the weld bead to meet the required specifications.

10

Finish the weld: Once the desired welding length is achieved, gradually reduce the welding current and allow the weld to cool down naturally. Remove any slag or spatter from the weld surface using appropriate tools.

Who needs shielded metal arc welding:

01

Professionals in the metalworking industry: Welders, fabricators, and manufacturers who work with various types of metals often require shielded metal arc welding to join metal components.

02

Construction and infrastructure sectors: Shielded metal arc welding is commonly used in the construction and infrastructure sectors to fabricate and repair metal structures, pipelines, bridges, and buildings.

03

Industrial maintenance and repair technicians: Professionals responsible for maintaining and repairing machinery, equipment, and structures often utilize shielded metal arc welding to fix metal components or perform onsite fabrications.

04

Automotive and transportation industry: Shielded metal arc welding is employed in the manufacturing and repair processes of vehicles, trailers, and other transportation equipment.

05

Artistic and creative applications: Artists, sculptors, and artisans may use shielded metal arc welding in creating metal sculptures, decorative pieces, and customized metalwork.

06

DIY enthusiasts and hobbyists: Individuals with a passion for metalworking or do-it-yourself projects may learn shielded metal arc welding techniques for personal projects, repairs, or creative pursuits.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is shielded metal arc welding?

Shielded metal arc welding is a welding process that uses a flux-covered electrode to form a weld.

Who is required to file shielded metal arc welding?

Welders and welding companies who perform shielded metal arc welding are required to file records of the welding process.

How to fill out shielded metal arc welding?

To fill out shielded metal arc welding, the welder or welding company must document the details of the welding job including date, location, materials used, and welding parameters.

What is the purpose of shielded metal arc welding?

The purpose of shielded metal arc welding is to join metal pieces together by creating a strong and durable weld.

What information must be reported on shielded metal arc welding?

The information that must be reported on shielded metal arc welding includes details of the welding job such as date, location, materials used, and welding parameters.

How do I make changes in shielded metal arc welding?

pdfFiller not only allows you to edit the content of your files but fully rearrange them by changing the number and sequence of pages. Upload your shielded metal arc welding to the editor and make any required adjustments in a couple of clicks. The editor enables you to blackout, type, and erase text in PDFs, add images, sticky notes and text boxes, and much more.

Can I create an electronic signature for the shielded metal arc welding in Chrome?

You certainly can. You get not just a feature-rich PDF editor and fillable form builder with pdfFiller, but also a robust e-signature solution that you can add right to your Chrome browser. You may use our addon to produce a legally enforceable eSignature by typing, sketching, or photographing your signature with your webcam. Choose your preferred method and eSign your shielded metal arc welding in minutes.

How can I edit shielded metal arc welding on a smartphone?

The best way to make changes to documents on a mobile device is to use pdfFiller's apps for iOS and Android. You may get them from the Apple Store and Google Play. Learn more about the apps here. To start editing shielded metal arc welding, you need to install and log in to the app.

Fill out your shielded metal arc welding online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Shielded Metal Arc Welding is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.