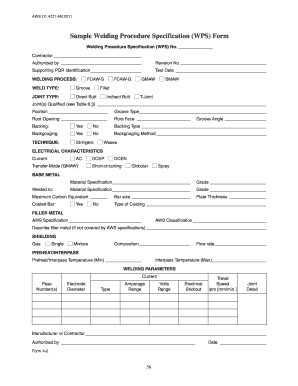

Welding Blank Sample WPS Form (GTAW & SMAW) 2013-2024 free printable template

Show details

Blank Sample WPS Form (GTA & SAW) WELDING PROCEDURE SPECIFICATION (WPS) Company Name WPS No. Authorized supporting PQR(s)BASE METALSDateSpecificationType or Grade AWS Group No. Rev. No.BASE METAL

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign

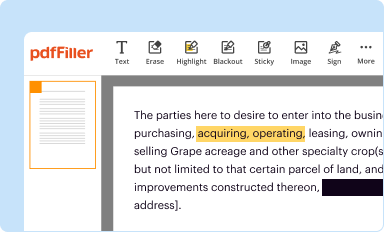

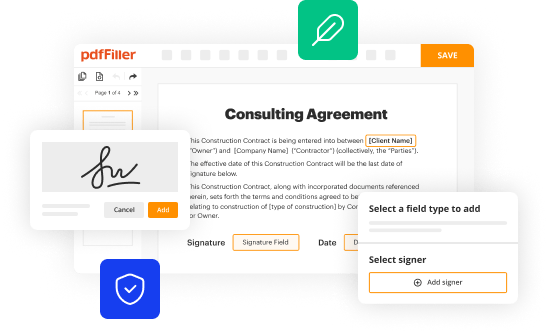

Edit your gtaw wps form form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

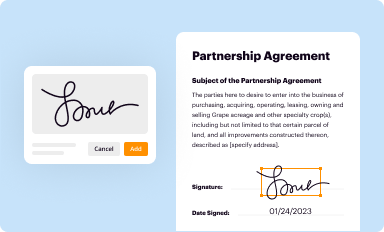

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your gtaw wps form form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing gtaw wps online

Use the instructions below to start using our professional PDF editor:

1

Register the account. Begin by clicking Start Free Trial and create a profile if you are a new user.

2

Upload a document. Select Add New on your Dashboard and transfer a file into the system in one of the following ways: by uploading it from your device or importing from the cloud, web, or internal mail. Then, click Start editing.

3

Edit sample welding procedure specification form. Add and replace text, insert new objects, rearrange pages, add watermarks and page numbers, and more. Click Done when you are finished editing and go to the Documents tab to merge, split, lock or unlock the file.

4

Save your file. Select it from your records list. Then, click the right toolbar and select one of the various exporting options: save in numerous formats, download as PDF, email, or cloud.

pdfFiller makes working with documents easier than you could ever imagine. Register for an account and see for yourself!

How to fill out gtaw wps form

How to fill out gtaw wps?

01

Gather all necessary information regarding the welding project, such as material type, thickness, and joint configuration.

02

Determine the appropriate welding parameters, including amperage, voltage, travel speed, and shielding gas type.

03

Identify the required pre-weld and post-weld heat treatments, if applicable.

04

Follow the provided WPS form, filling out each section accurately and legibly.

05

Provide detailed information about the base metal, filler metal, and any additional materials used in the welding process.

06

Document the welding technique and position used, highlighting any specific instructions or precautions.

07

Include any additional considerations or special requirements, such as back purging or surface preparation.

08

Review the completed WPS for accuracy and completeness before submitting it for approval.

Who needs gtaw wps?

01

Welding contractors and fabricators who use the Gas Tungsten Arc Welding (GTAW) process for various projects.

02

Manufacturing industries that require precise and high-quality welds on materials such as stainless steel, aluminum, and titanium.

03

Inspectors and quality control personnel who verify compliance with welding codes and standards.

04

Welders who need a documented procedure to ensure consistent and repeatable weld quality.

05

Engineering and design professionals who develop welding specifications and procedures for their projects.

06

Companies involved in industries such as aerospace, automotive, oil and gas, and nuclear power, where GTAW is commonly used.

Fill blank sample wps form : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is gtaw wps?

GTAW stands for Gas Tungsten Arc Welding, which is a type of arc welding process that uses a non-consumable tungsten electrode to produce the weld. The electrode creates a high-temperature arc that melts the base metal and filler material (if used) to form a weld joint.

WPS stands for Welding Procedure Specification, which is a document that outlines the details of a specific welding process. It includes information such as welding parameters, joint details, pre-weld and post-weld processes, and any additional requirements necessary for a specific welding job.

So, "GTAW WPS" refers to a Welding Procedure Specification for Gas Tungsten Arc Welding process.

Who is required to file gtaw wps?

Individuals or businesses who meet the following criteria are required to file a GTAW (Gas Tungsten Arc Welding) WPS (Welding Procedure Specification):

1. Welding Contractors: Contractors who perform GTAW welding operations must file a GTAW WPS with relevant authorities or clients to demonstrate compliance with welding standards and specifications.

2. Welding Fabricators: Companies or individuals engaged in fabrication work that involves GTAW welding processes are generally required to file GTAW WPS to ensure the quality and integrity of their welding procedures.

3. Regulatory Bodies: Some regulatory bodies may require GTAW WPS filings as part of their compliance and certification processes. This applies to organizations that need to obtain and maintain certain certifications or permits related to welding operations.

It is important to note that specific requirements for filing GTAW WPS may vary depending on regional regulations, industry standards, and client requirements. It is recommended to consult relevant authorities or industry experts to determine the exact filing requirements in a particular situation.

How to fill out gtaw wps?

To fill out the GTAW (Gas Tungsten Arc Welding) WPS (Welding Procedure Specification), follow these steps:

1. Start by gathering all the required information such as project details, welding code or standard, material specifications, joint design, welding position, and any special requirements or procedures.

2. Identify the base metal to be welded, including its type, grade, and thickness. Also, determine if any filler metal is required and specify its type and grade.

3. Determine the welding process, in this case, GTAW, and specify it in the WPS.

4. Identify the shielding gas to be used during the welding process, along with its composition, flow rate, and any specific requirements.

5. Define the welding parameters such as amperage, voltage, travel speed, preheat/interpass temperature, and post-weld heat treatment, if applicable. Make sure to refer to the appropriate code or standard for recommended values.

6. Specify the joint details, including the joint configuration (e.g., butt, fillet, etc.) and any specific joint preparation requirements (e.g., bevel angles, root openings, etc.).

7. Include any additional information or requirements regarding cleanliness, cleaning methods, fit-up tolerances, backing gas, etc.

8. Review and ensure that the WPS complies with the welding code or standard requirements and any project-specific guidelines or specifications.

9. Sign and date the completed WPS, including the name and signature of the qualified welding engineer or individual responsible for its development.

10. Once the WPS is completed, it may need to be submitted to the appropriate welding authority or governing body for approval, depending on the project requirements.

Remember, it is essential to follow the specific guidelines and requirements provided by the welding code or standard applicable to the particular project, as they might include additional or different information than mentioned above.

What is the purpose of gtaw wps?

The purpose of GTAW WPS (Gas Tungsten Arc Welding Welding Procedure Specification) is to provide guidelines and instructions for the process of gas tungsten arc welding. It outlines the necessary controls, parameters, and techniques required to ensure a successful and reliable weld. The GTAW WPS covers aspects such as base metals, filler material, pre-weld and post-weld treatments, amperage, voltage, travel speed, shielding gas, and other variables. It aims to ensure standardization and quality control in the welding process, promoting the production of consistent and high-quality welds.

What information must be reported on gtaw wps?

The information that must be reported on the GTAW (Gas Tungsten Arc Welding) WPS (Welding Procedure Specification) includes:

1. General Information: This includes the name of the welding procedure, the welding process (GTAW), and the applicable codes or standards.

2. Welding Procedure Identification: It includes a unique identification number or code for the welding procedure.

3. Base Metal Information: This includes the type and specification of the base metal being welded, such as the material grade, thickness, and dimensions.

4. Weld Joint Details: It includes a description of the joint design, such as the joint type (butt, fillet, etc.) and dimensions.

5. Welding Filler Metal: It includes the specification and classification of the welding filler metal, including the designation, grade, and diameter.

6. Welding Parameters: It includes the specific welding parameters required for the GTAW process, such as the welding current, voltage, travel speed, gas flow rate, pre-heat/post-heat temperatures, and any specialized techniques or settings.

7. Heat Input: It includes the calculated heat input, which is the amount of energy transferred into the base metal during welding. Heat input is typically measured in joules or kilojoules per unit length.

8. Preheat and Interpass Temperature Requirements: It specifies any preheating or interpass temperature requirements for the base metal to ensure proper weld quality and prevention of cracking or distortion.

9. Welding Technique and Sequence: It outlines the recommended welding technique and sequence for achieving the specified weld quality, including any specific instructions for electrode manipulation or positional requirements.

10. Testing and Inspection: It details the required non-destructive testing (NDT) or destructive testing (DT) methods, such as visual inspection, liquid penetrant testing, radiographic examination, or mechanical testing, to be performed on the completed welds.

11. Welding Personnel Qualification: It specifies the qualification requirements for the welding personnel, including their certifications, training records, and any additional requirements or restrictions.

12. Acceptance Criteria: It defines the acceptance criteria and allowable defects or discontinuities for the completed welds based on the applicable codes or standards.

These are some of the key information that should be reported on a GTAW WPS, but additional specific requirements may vary depending on the project, industry, or applicable welding codes and standards.

How can I manage my gtaw wps directly from Gmail?

pdfFiller’s add-on for Gmail enables you to create, edit, fill out and eSign your sample welding procedure specification form and any other documents you receive right in your inbox. Visit Google Workspace Marketplace and install pdfFiller for Gmail. Get rid of time-consuming steps and manage your documents and eSignatures effortlessly.

Where do I find sample wps smaw?

The pdfFiller premium subscription gives you access to a large library of fillable forms (over 25 million fillable templates) that you can download, fill out, print, and sign. In the library, you'll have no problem discovering state-specific sample gtaw and other forms. Find the template you want and tweak it with powerful editing tools.

How do I make edits in wps form without leaving Chrome?

Adding the pdfFiller Google Chrome Extension to your web browser will allow you to start editing smaw wps form and other documents right away when you search for them on a Google page. People who use Chrome can use the service to make changes to their files while they are on the Chrome browser. pdfFiller lets you make fillable documents and make changes to existing PDFs from any internet-connected device.

Fill out your gtaw wps form online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Sample Wps Smaw is not the form you're looking for?Search for another form here.

Keywords relevant to wps gtaw smaw form

Related to blank sample wps

If you believe that this page should be taken down, please follow our DMCA take down process

here

.