Get the free XPress Compression Molded

Show details

Press Compression Molded

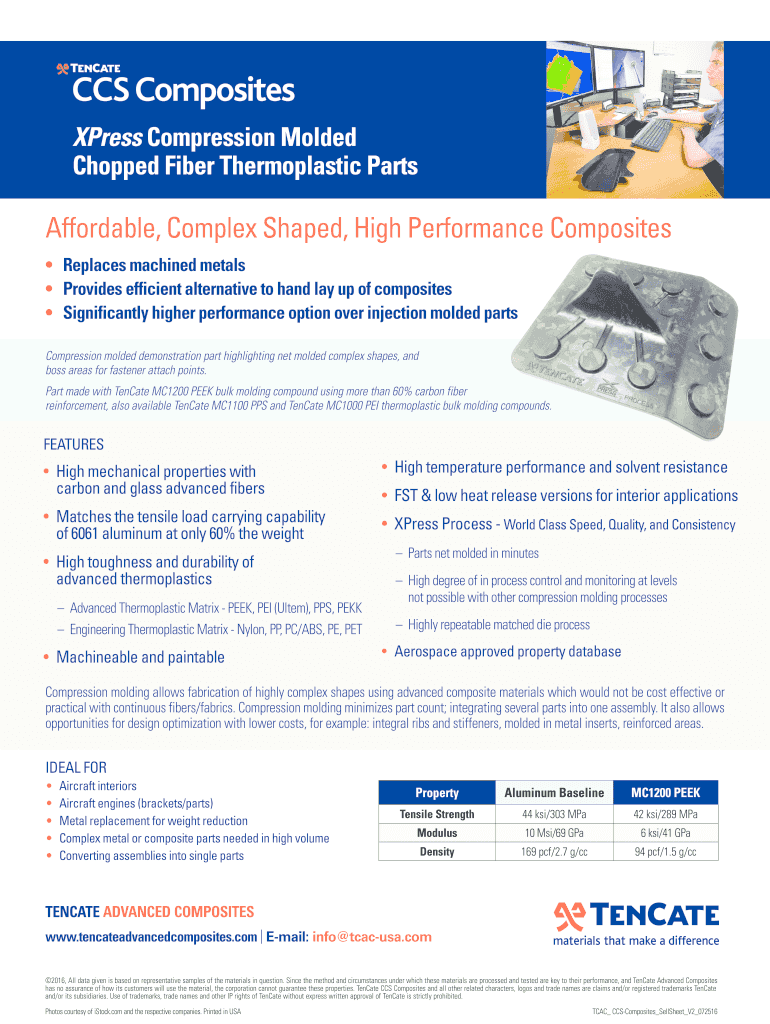

Chopped Fiber Thermoplastic PartsAffordable, Complex Shaped, High Performance Composites

Replaces machined metals

Provides efficient alternative to hand lay up of composites

Significantly

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign xpress compression molded

Edit your xpress compression molded form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your xpress compression molded form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit xpress compression molded online

To use our professional PDF editor, follow these steps:

1

Log in to your account. Start Free Trial and register a profile if you don't have one.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit xpress compression molded. Replace text, adding objects, rearranging pages, and more. Then select the Documents tab to combine, divide, lock or unlock the file.

4

Get your file. Select your file from the documents list and pick your export method. You may save it as a PDF, email it, or upload it to the cloud.

pdfFiller makes dealing with documents a breeze. Create an account to find out!

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out xpress compression molded

How to fill out xpress compression molded

01

To fill out xpress compression molded, follow these steps:

02

Prepare the materials needed for the molding process, such as the mold, resin, and any additives or reinforcements.

03

Clean the mold thoroughly to ensure there are no contaminants or debris that could affect the molding process.

04

Preheat the mold to the appropriate temperature, typically specified by the manufacturer or process guidelines.

05

Measure and mix the correct ratio of resin and any additives or reinforcements, following the manufacturer's instructions.

06

Pour or inject the resin mixture into the mold, ensuring it is evenly distributed and fills all desired areas.

07

Close the mold and apply the necessary pressure or compression to the mold, typically using a hydraulic or mechanical press.

08

Maintain the pressure and temperature for the required curing time, allowing the resin to solidify and form the molded part.

09

Once the curing time is complete, release the pressure and open the mold carefully.

10

Remove the xpress compression molded part from the mold, inspect for any defects or flaws, and perform any necessary post-processing or finishing steps.

11

Repeat the process as necessary to produce additional xpress compression molded parts.

Who needs xpress compression molded?

01

Xpress compression molded is needed by various industries and applications that require precise and high-quality molded parts. Some examples of who needs xpress compression molded are:

02

- Automotive industry for manufacturing components like interior trim, body panels, and structural parts.

03

- Aerospace industry for producing lightweight and durable parts like aircraft interiors, engine components, and structural elements.

04

- Medical industry for creating customized and high-performance medical devices, implants, and prosthetics.

05

- Consumer goods industry for manufacturing products like appliances, electronics, and furniture components.

06

- Industrial and manufacturing sectors for producing a wide range of parts used in machinery, equipment, and infrastructure.

07

These are just a few examples, but xpress compression molded can be utilized by any industry or application that requires precise and efficient molding of various materials.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How do I execute xpress compression molded online?

Filling out and eSigning xpress compression molded is now simple. The solution allows you to change and reorganize PDF text, add fillable fields, and eSign the document. Start a free trial of pdfFiller, the best document editing solution.

How do I fill out xpress compression molded using my mobile device?

Use the pdfFiller mobile app to fill out and sign xpress compression molded. Visit our website (https://edit-pdf-ios-android.pdffiller.com/) to learn more about our mobile applications, their features, and how to get started.

How do I edit xpress compression molded on an iOS device?

Use the pdfFiller mobile app to create, edit, and share xpress compression molded from your iOS device. Install it from the Apple Store in seconds. You can benefit from a free trial and choose a subscription that suits your needs.

What is xpress compression molded?

Xpress compression molded is a manufacturing process that involves using high pressure to create products out of materials such as plastics, rubber, or composites.

Who is required to file xpress compression molded?

Anyone involved in the manufacturing or production of products using the xpress compression molded process may be required to file reports related to compliance, quality control, or regulatory requirements.

How to fill out xpress compression molded?

Filling out reports related to xpress compression molded may involve documenting details of the manufacturing process, materials used, quality control measures, and compliance with regulations.

What is the purpose of xpress compression molded?

The purpose of xpress compression molded is to efficiently and effectively produce high-quality products using a specific manufacturing process that involves compression under high pressure.

What information must be reported on xpress compression molded?

Information that may need to be reported on xpress compression molded includes details of the manufacturing process, materials used, quality control measures, and compliance with regulations.

Fill out your xpress compression molded online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Xpress Compression Molded is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.