Fort Worth Operations SPF 02-01 2008-2026 free printable template

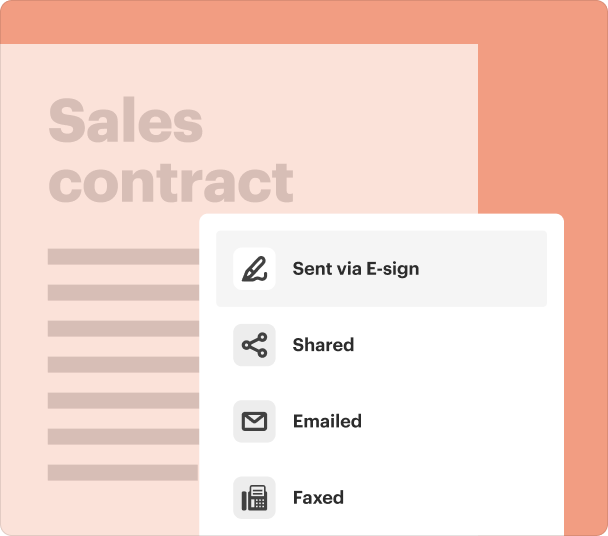

Fill out, sign, and share forms from a single PDF platform

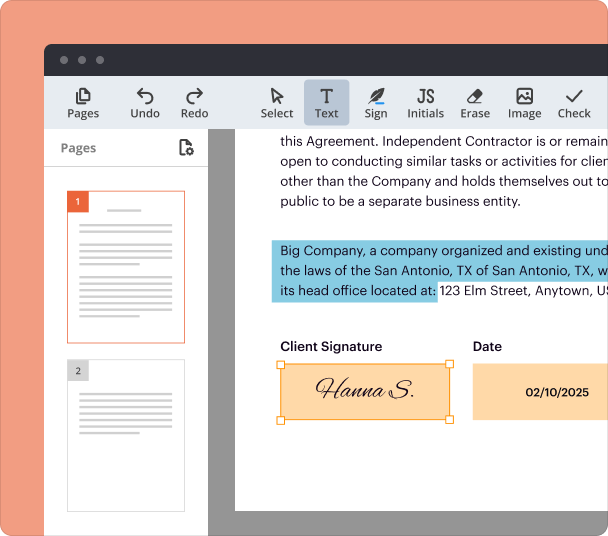

Edit and sign in one place

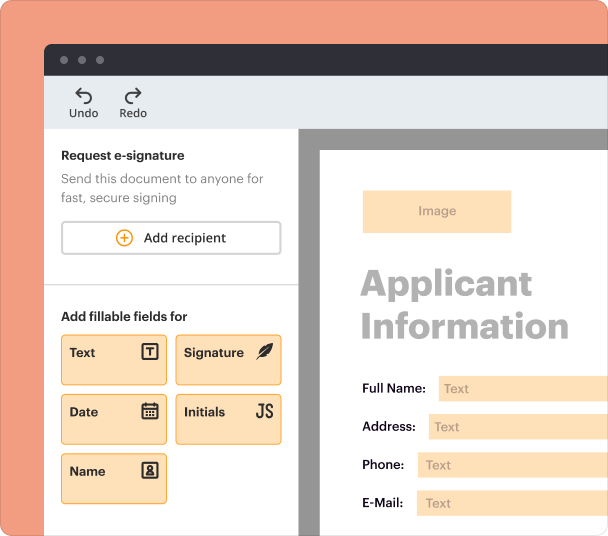

Create professional forms

Simplify data collection

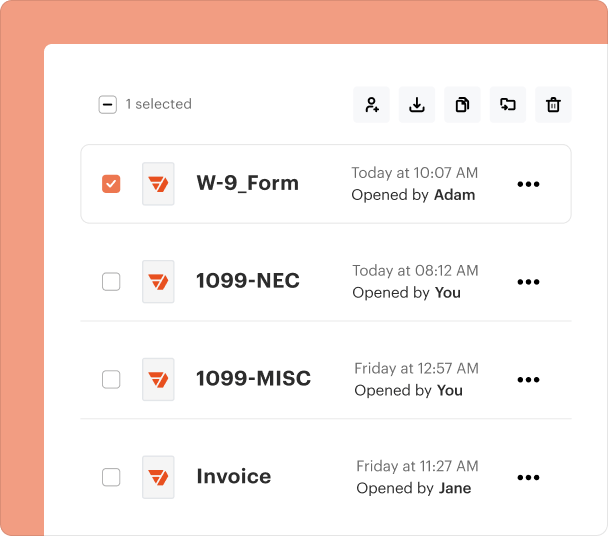

Manage forms centrally

Why pdfFiller is the best tool for your documents and forms

End-to-end document management

Accessible from anywhere

Secure and compliant

Comprehensive Guide to Fort Worth Operations SPF Form

The Fort Worth Operations SPF form is essential for ensuring compliance with AS9102 standards in aerospace manufacturing. This guide provides clear instructions on how to fill out the Fort Worth operations SPF form, manage document submissions, and avoid common pitfalls.

What is the Fort Worth Operations SPF Form?

The SPF form, or Standard Parts Form, is vital in tracking the compliance and quality of parts delivered for production. It plays a significant role in ensuring that all design and manufacturing processes adhere to aerospace standards. Each manufacturer is required to fill out this form to provide transparency in operations.

-

The SPF form serves as proof that all parts meet the specified standards and requirements. This ensures quality control and helps avoid costly errors.

-

All manufacturers and suppliers involved in the aerospace industry, especially those working with Fort Worth operations, need to complete this form to meet compliance standards.

How do you fill out the SPF 02-01 fields?

Understanding the fields on the SPF 02-01 form is crucial for accurate completion. Each field has specific requirements which can affect both compliance and production processes.

-

The fields are categorized based on their importance: Required (R), Conditional Required (CR), and Optional (O), helping users prioritize the information needed.

-

Typical fields include Part Number, Part Name, and Serial Number. Each entry should be completed thoroughly to ensure accuracy.

Additionally, users need to interpret each field correctly to ensure a seamless submission process.

What are the steps for completing the SPF form?

-

Before starting, gather all necessary documents such as part specifications and previous compliance reports to ensure accuracy in your entries.

-

Navigate through the pdfFiller platform to fill out the form, upload any supporting documents, and save your work as you progress.

-

Follow the outlined steps to submit your form and consider using the verification process available in pdfFiller to double-check your information.

What are some examples and case studies?

-

Reviewing a fully filled SPF 02-01 can illustrate proper documentation practices and highlight why thoroughness is critical.

-

Discussing real-world consequences of incorrect form completion, such as delays in production or compliance failures, emphasizes the need for attention to detail.

-

Case studies demonstrating how companies effectively used pdfFiller for managing their operations provide valuable insights.

What are common mistakes and how to avoid them?

Many users encounter common pitfalls when completing the SPF 02-01. Learning to identify these errors can save time and reduce frustration.

-

Missing fields and misinterpretation of requirements are prevalent. It is crucial to ensure all fields are completed and understood as per the guidelines.

-

Understanding regional differences in form requirements can also help to avoid complications in the submission process.

What are best practices for compliance and record-keeping?

-

Maintaining precise records is essential for audit readiness. This helps in demonstrating compliance with AS9102 even during unexpected inspections.

-

Adopt recommended electronic storage practices for easy access and security of documentation.

-

Stay informed about compliance requirements specific to the Fort Worth area to ensure that your operations meet all necessary regulations.

How can pdfFiller enhance your document management?

pdfFiller empowers users by providing robust features for editing PDFs, eSigning documents, and collaborative work within the cloud. This platform streamlines the process of managing documents like the Fort Worth operations SPF form.

-

Users can easily edit their documents and forms, making it simple to update necessary information quickly.

-

Collaboration with team members becomes easier, allowing for real-time updates and comments.

-

Integrate the SPF form into your workflow, simplifying submission and ensuring compliance through an organized system.

Frequently Asked Questions about as9102 rev c pdf form

What is an SPF form?

An SPF form, or Standard Parts Form, tracks the compliance and quality of manufactured parts, specifically in aerospace industries. It verifies that all parts meet the required standards and are properly documented.

Who is required to complete the SPF 02-01 form?

Any manufacturer or supplier involved in the aerospace sector, particularly those in regions like Fort Worth, must fill out the SPF 02-01 form to maintain compliance with industry standards and regulations.

What are the key fields in the SPF 02-01 form?

Key fields include Part Number, Part Name, and Serial Number. Each field must be completed accurately to ensure compliance and avoid errors during audits.

What can I do if I make a mistake on the SPF form?

If a mistake occurs, it's crucial to correct it before submission. Review the relevant regulations and consider using pdfFiller's editing tools for easy adjustments.

How can pdfFiller assist with SPF form management?

pdfFiller offers features like PDF editing, eSigning, and collaborative tools that can significantly enhance the efficiency of managing the SPF form, ensuring a smooth workflow and compliance.

pdfFiller scores top ratings on review platforms