CO AST Monthly Visual Inspection Checklist 2013-2026 free printable template

Show details

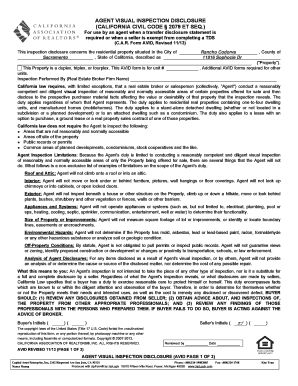

This document is a checklist for the monthly visual inspection of aboveground storage tanks, ensuring they are in compliance with safety regulations and free from leaks and other hazards.

pdfFiller is not affiliated with any government organization

Get, Create, Make and Sign pcb visual inspection checklist form

Edit your visual inspection procedure pdf form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your lev checklist template form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing lev monthly inspection checklist online

To use the professional PDF editor, follow these steps below:

1

Log in to your account. Start Free Trial and sign up a profile if you don't have one yet.

2

Prepare a file. Use the Add New button to start a new project. Then, using your device, upload your file to the system by importing it from internal mail, the cloud, or adding its URL.

3

Edit visual inspection pdf form. Replace text, adding objects, rearranging pages, and more. Then select the Documents tab to combine, divide, lock or unlock the file.

4

Save your file. Select it in the list of your records. Then, move the cursor to the right toolbar and choose one of the available exporting methods: save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out CO AST Monthly Visual Inspection Checklist

How to fill out CO AST Monthly Visual Inspection Checklist

01

Obtain the CO AST Monthly Visual Inspection Checklist form.

02

Review the checklist for the specific items to be inspected.

03

Start with the inspection date and fill in the data at the top of the form.

04

Inspect the aboveground storage tank (AST) for any visible signs of leaks, corrosion, or damage.

05

Check the condition of the tank's fittings, valves, and piping connections.

06

Assess the integrity of the secondary containment area, ensuring it is free from debris and damage.

07

Note any irregularities or maintenance needs directly on the checklist.

08

Complete the checklist by providing your name and signature, along with the date of completion.

09

Submit the completed checklist to the designated supervisor or environmental compliance officer.

Who needs CO AST Monthly Visual Inspection Checklist?

01

Individuals responsible for environmental compliance.

02

Facility managers overseeing aboveground storage tanks.

03

Maintenance personnel tasked with inspecting storage tanks.

04

Regulatory bodies requiring documentation of inspections.

Fill

form

: Try Risk Free

People Also Ask about

How do you document visual inspection?

Visual Inspection Report Form Indicate product ID and location. Capture photo evidence of products and/or defects. Determine pass/fail decisions based on a reference image. Identify visual defects based on defect criteria. Complete the visual inspection with a digital signature.

What is a general visual inspection?

A visual examination of an interior or exterior area, installation or assembly to detect obvious damage, failure or irregularity.

What items should be on the inspection checklist?

Inspection Checklists - General Information Environment. dust, gases, fumes, sprays, lighting, noise, ventilation. Buildings. windows, doors, floors, stairs, roofs, walls, elevators. Containers. Electrical. Fire protection equipment. Hand tools. Hazardous products. Materials handling.

What are the requirements of visual inspection?

Visual Inspection Report Form Indicate product ID and location. Capture photo evidence of products and/or defects. Determine pass/fail decisions based on a reference image. Identify visual defects based on defect criteria. Complete the visual inspection with a digital signature.

What is basic visual inspection?

What is visual inspection? Visual inspection is a technique for detecting defects using the naked eye to ensure equipment is working properly or that manufactured products are being made to specification. This can include visual inspections done in person or remotely using digital images.

What is the visual inspection checklist for piping systems?

Visual inspection is the first step in assessing a pipe's condition. Features to observe are cracks, erosion, corrosion, debris, grinding, scouring, welding, manufacturing defects, discolouration, weld splatter, location of insertions and state of the coating.

How do you write an inspection report?

Inspection Report Writing: 8 Best Practices Don't rush it. Know your report writing template. Cater each report to the property. Stick to the facts. Be concise and understandable. Take LOTS of photos. Manage your risk.

How do you write a visual inspection report?

Visual Inspection Report Form Indicate product ID and location. Capture photo evidence of products and/or defects. Determine pass/fail decisions based on a reference image. Identify visual defects based on defect criteria. Complete the visual inspection with a digital signature.

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I modify CO AST Monthly Visual Inspection Checklist without leaving Google Drive?

Using pdfFiller with Google Docs allows you to create, amend, and sign documents straight from your Google Drive. The add-on turns your CO AST Monthly Visual Inspection Checklist into a dynamic fillable form that you can manage and eSign from anywhere.

How can I edit CO AST Monthly Visual Inspection Checklist on a smartphone?

The pdfFiller apps for iOS and Android smartphones are available in the Apple Store and Google Play Store. You may also get the program at https://edit-pdf-ios-android.pdffiller.com/. Open the web app, sign in, and start editing CO AST Monthly Visual Inspection Checklist.

How do I fill out CO AST Monthly Visual Inspection Checklist using my mobile device?

You can quickly make and fill out legal forms with the help of the pdfFiller app on your phone. Complete and sign CO AST Monthly Visual Inspection Checklist and other documents on your mobile device using the application. If you want to learn more about how the PDF editor works, go to pdfFiller.com.

What is CO AST Monthly Visual Inspection Checklist?

The CO AST Monthly Visual Inspection Checklist is a document used to ensure that Aboveground Storage Tanks (ASTs) containing potentially hazardous substances are visually inspected on a monthly basis to identify any signs of leaks, corrosion, spills, or other operational problems.

Who is required to file CO AST Monthly Visual Inspection Checklist?

Operators of facilities that have Aboveground Storage Tanks (ASTs) containing regulated substances are required to file the CO AST Monthly Visual Inspection Checklist as part of their environmental compliance obligations.

How to fill out CO AST Monthly Visual Inspection Checklist?

To fill out the CO AST Monthly Visual Inspection Checklist, the inspector should complete each section by noting the date of inspection, observing and recording the condition of the tank, checking for any leaks or issues, and providing comments on the overall status of the tank. Any deficiencies must be documented and corrective actions should be noted.

What is the purpose of CO AST Monthly Visual Inspection Checklist?

The purpose of the CO AST Monthly Visual Inspection Checklist is to maintain safety and environmental protection by ensuring that Aboveground Storage Tanks are regularly monitored for integrity and functionality, preventing leaks and potential hazards.

What information must be reported on CO AST Monthly Visual Inspection Checklist?

The information that must be reported on the CO AST Monthly Visual Inspection Checklist includes the date of inspection, tank identification, visual observations, conditions of the tank and surrounding area, any signs of leaks or corrosion, and any corrective actions taken or needed.

Fill out your CO AST Monthly Visual Inspection Checklist online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

CO AST Monthly Visual Inspection Checklist is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.