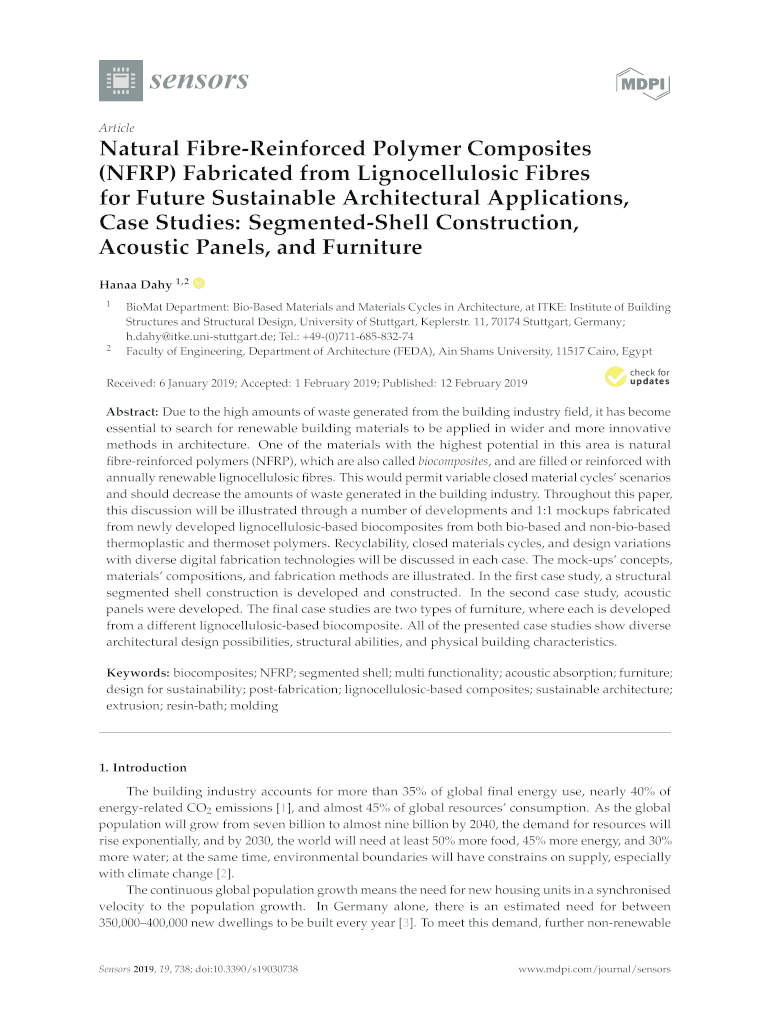

Get the free Natural Fibre-Reinforced Polymer Composites (NFRP) Fabricated from Lignocellulosic F...

Show details

Sensors

ArticleNatural FibreReinforced Polymer Composites

(CFRP) Fabricated from Lignocellulosic Fibers

for Future Sustainable Architectural Applications,

Case Studies: Segmented Shell Construction,

Acoustic

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign natural fibre-reinforced polymer composites

Edit your natural fibre-reinforced polymer composites form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your natural fibre-reinforced polymer composites form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit natural fibre-reinforced polymer composites online

To use the professional PDF editor, follow these steps below:

1

Check your account. If you don't have a profile yet, click Start Free Trial and sign up for one.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit natural fibre-reinforced polymer composites. Rearrange and rotate pages, insert new and alter existing texts, add new objects, and take advantage of other helpful tools. Click Done to apply changes and return to your Dashboard. Go to the Documents tab to access merging, splitting, locking, or unlocking functions.

4

Save your file. Select it from your list of records. Then, move your cursor to the right toolbar and choose one of the exporting options. You can save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud, among other things.

With pdfFiller, it's always easy to deal with documents.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out natural fibre-reinforced polymer composites

How to fill out natural fibre-reinforced polymer composites

01

Start by selecting the appropriate natural fibres and polymers for your composite. This typically depends on the desired properties and application of the final product.

02

Clean and prepare the natural fibres by removing any impurities, such as dust or dirt. This can be done through processes like washing or drying.

03

Mix the natural fibres with the polymer matrix in the desired ratio. This can be achieved by using methods like melt blending or solution blending.

04

Apply pressure and heat to the mixture to facilitate the bonding between the fibres and the polymer. This step is crucial for achieving a strong and durable composite.

05

Shape the composite material into the desired form, either through molding or extrusion techniques.

06

Allow the composite to cool and solidify, ensuring that the fibres are well-embedded within the polymer matrix.

07

Perform any necessary post-processing steps, such as trimming or sanding, to achieve the desired final shape and finish of the composite product.

08

Test the mechanical, thermal, and other properties of the composite to ensure it meets the required specifications.

09

If necessary, make any adjustments to the composition or processing parameters to optimize the properties of the composite.

10

Finally, document and evaluate the manufacturing process for future reference and improvement.

Who needs natural fibre-reinforced polymer composites?

01

Industries that require lightweight materials with high strength and durability may need natural fibre-reinforced polymer composites. These materials offer a good balance between weight reduction and mechanical performance.

02

Automotive manufacturers can benefit from using natural fibre-reinforced polymer composites in components like car interiors, body panels, and even structural parts. The composites can reduce weight, improve fuel efficiency, and provide better impact resistance.

03

Construction companies may use natural fibre-reinforced composites in applications such as façade cladding, roofing, and insulation. These composites can provide better thermal and acoustic insulation properties compared to traditional materials.

04

Aerospace and aviation industries can benefit from the use of natural fibre-reinforced polymer composites in aircraft components. The composites offer reduced weight, improved fuel efficiency, and increased resistance to impact and fatigue.

05

Renewable energy sectors, such as wind energy, can utilize natural fibre-reinforced polymer composites in turbine blades. These composites offer high strength-to-weight ratio, corrosion resistance, and fatigue performance, making them suitable for such applications.

06

Sporting goods manufacturers may find natural fibre-reinforced polymer composites useful in products like bicycles, tennis rackets, or snowboards. The composites can enhance performance by providing lightweight yet strong and rigid materials.

07

Furniture and interior design industries can incorporate natural fibre-reinforced polymer composites into products like chairs, tables, or decorative elements. The composites offer unique aesthetic qualities along with good mechanical performance.

08

Packaging manufacturers may use natural fibre-reinforced composites for sustainable and eco-friendly packaging solutions. These composites offer biodegradability, reduced carbon footprint, and good mechanical strength for packaging purposes.

Fill

form

: Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

How can I edit natural fibre-reinforced polymer composites from Google Drive?

People who need to keep track of documents and fill out forms quickly can connect PDF Filler to their Google Docs account. This means that they can make, edit, and sign documents right from their Google Drive. Make your natural fibre-reinforced polymer composites into a fillable form that you can manage and sign from any internet-connected device with this add-on.

Can I sign the natural fibre-reinforced polymer composites electronically in Chrome?

You can. With pdfFiller, you get a strong e-signature solution built right into your Chrome browser. Using our addon, you may produce a legally enforceable eSignature by typing, sketching, or photographing it. Choose your preferred method and eSign in minutes.

How do I complete natural fibre-reinforced polymer composites on an iOS device?

Install the pdfFiller iOS app. Log in or create an account to access the solution's editing features. Open your natural fibre-reinforced polymer composites by uploading it from your device or online storage. After filling in all relevant fields and eSigning if required, you may save or distribute the document.

What is natural fibre-reinforced polymer composites?

Natural fibre-reinforced polymer composites are materials made from a combination of natural fibres, such as hemp or flax, and a polymer resin, such as epoxy or polyester.

Who is required to file natural fibre-reinforced polymer composites?

Any company or individual involved in the production or use of natural fibre-reinforced polymer composites may be required to file information about their usage.

How to fill out natural fibre-reinforced polymer composites?

To fill out natural fibre-reinforced polymer composites, you will need to provide detailed information about the type and quantity of natural fibres used, the type of polymer resin used, and the intended application of the composite.

What is the purpose of natural fibre-reinforced polymer composites?

The purpose of natural fibre-reinforced polymer composites is to create materials that are lighter, stronger, and more environmentally friendly than traditional materials like metal or plastic.

What information must be reported on natural fibre-reinforced polymer composites?

Information that must be reported on natural fibre-reinforced polymer composites includes the type of natural fibres used, the type of polymer resin used, the manufacturing process, and any testing or performance data.

Fill out your natural fibre-reinforced polymer composites online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Natural Fibre-Reinforced Polymer Composites is not the form you're looking for?Search for another form here.

Relevant keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.